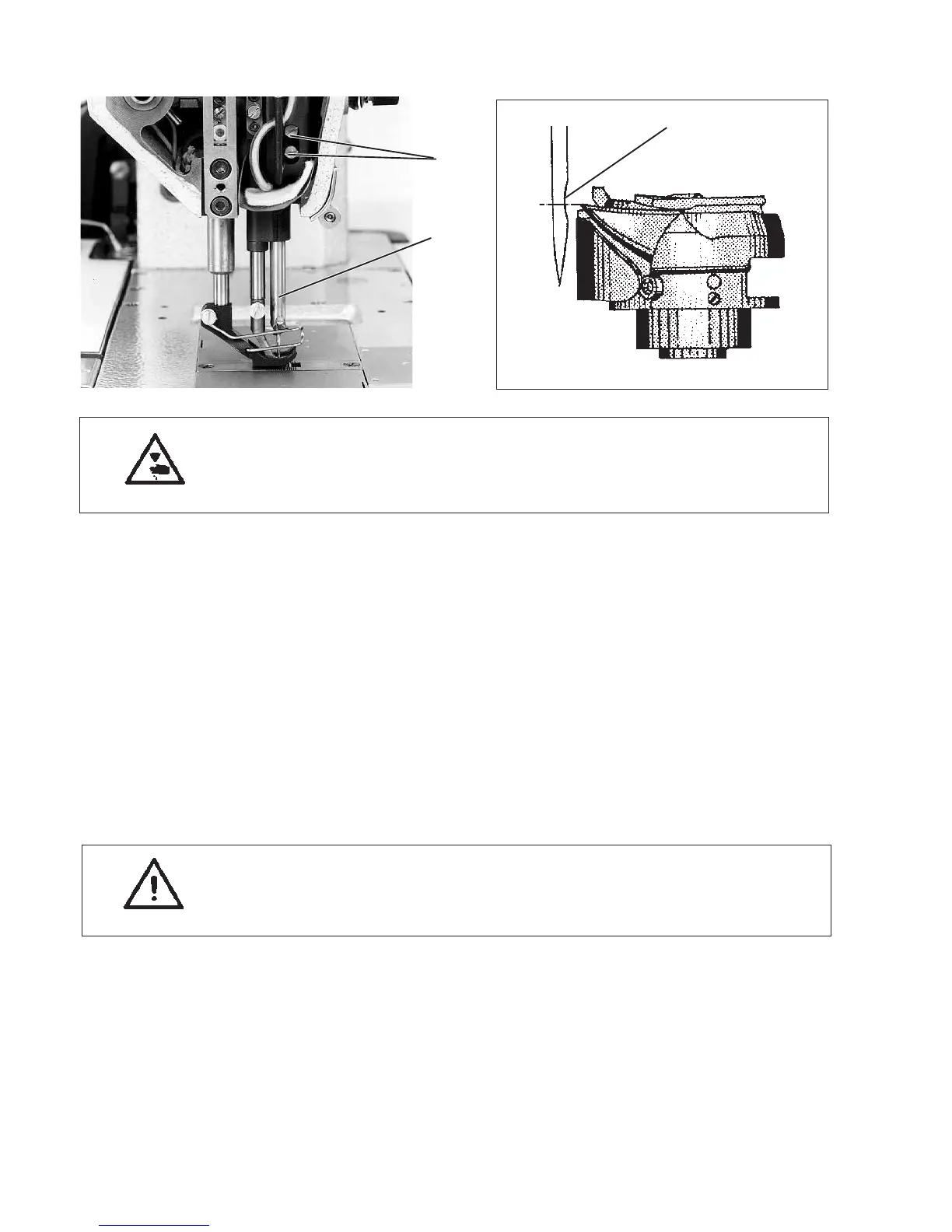

4.2 Needle bar height

Caution: Danger of injury !

Switch off main switch.

Check and adjust needle bar height only when sewing machine is

switched off.

Standard checking

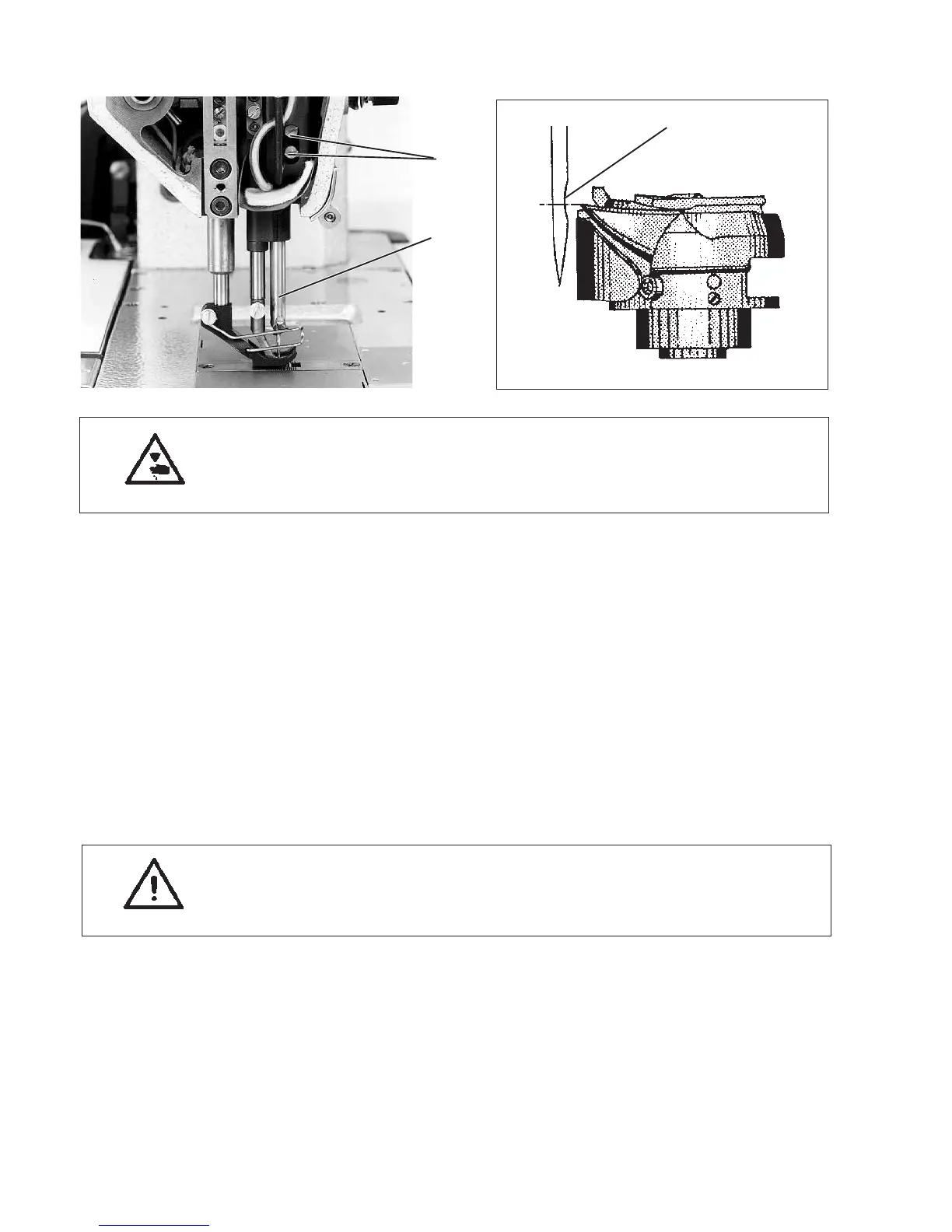

In looping stroke position the hook tip must be a t the level of the middle

of the needle hollow groove 3.

–

Move needle in looping stroke position by handwheel.

In looping stroke position the hook tip is at the level of the middle of

the needle.

–

Check position of the hook tip to the needle hollow groove 3.

Correction

–

Take off head cover.

–

Loosen both screws 1.

–

Adjust the height of needle bar 2 in such a way that the hook tip is

at the level of the middle of the needle hollow groove 3.

Attention!

Needle bar 2 must not be twisted when being shifted.

–

Tighten screws 1.

ATTENTION !

After a correction of the needle bar height:

Check position of the hook protection and correct it, if necessary.

A wrong adjustment of the needle bar height can have the following

consequences:

–

Damage to the hook tip

–

Jamming of the bobbin thread between needle and needle

protection

16

1

2

3

Loading...

Loading...