. .

Dyadic Systems – Mechatronics Cylinder Manual MF-005500-EN-23/63

4.1.5. Servo Amplifier Mounting and Environmental Installation Limits

(1) Ambient temperature under 40°C.

(2) Minimal shock and vibration. (should be lower than 0.5G)

(3) Environment free of corrosive gas and dust.

(4) Ambient humidity under 90%RH, non condensing.

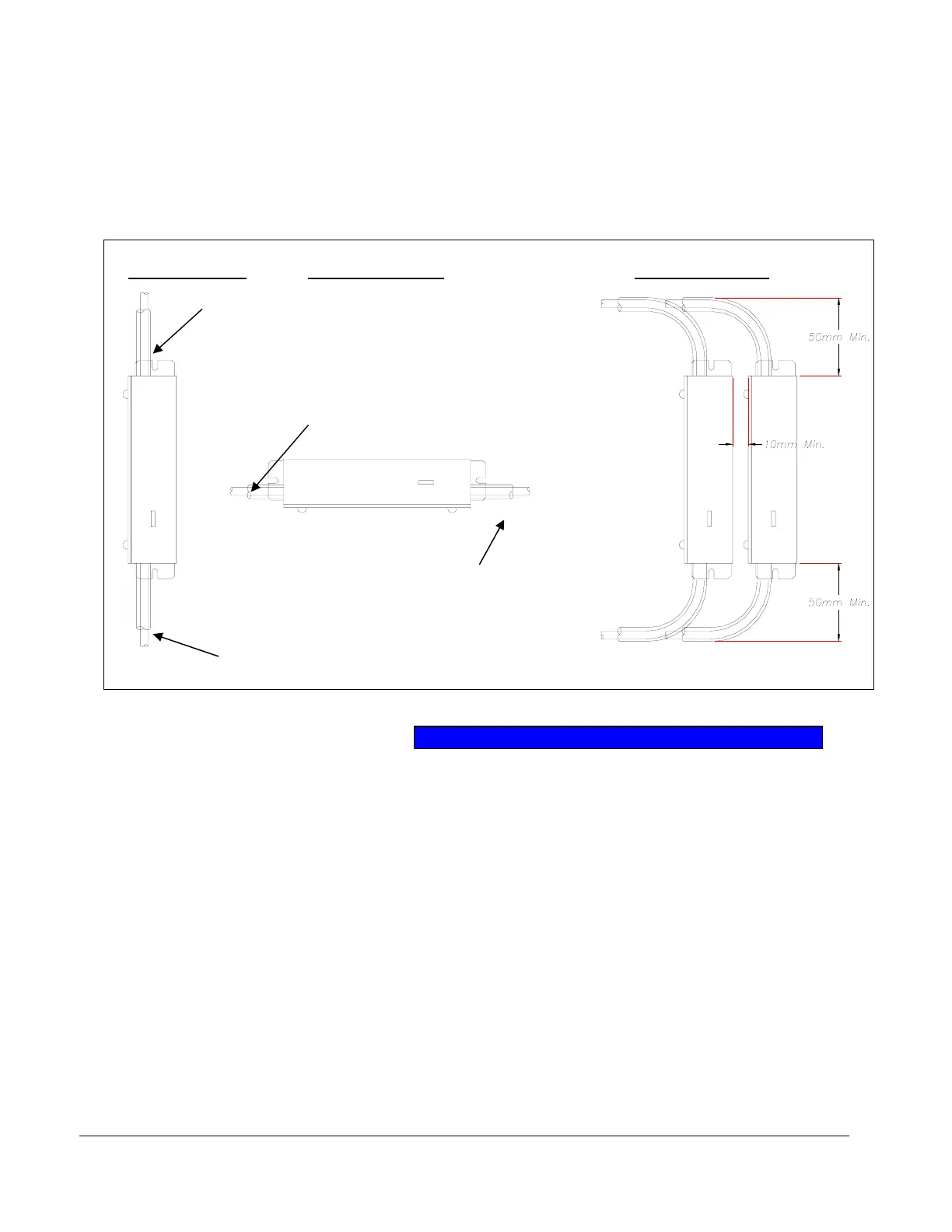

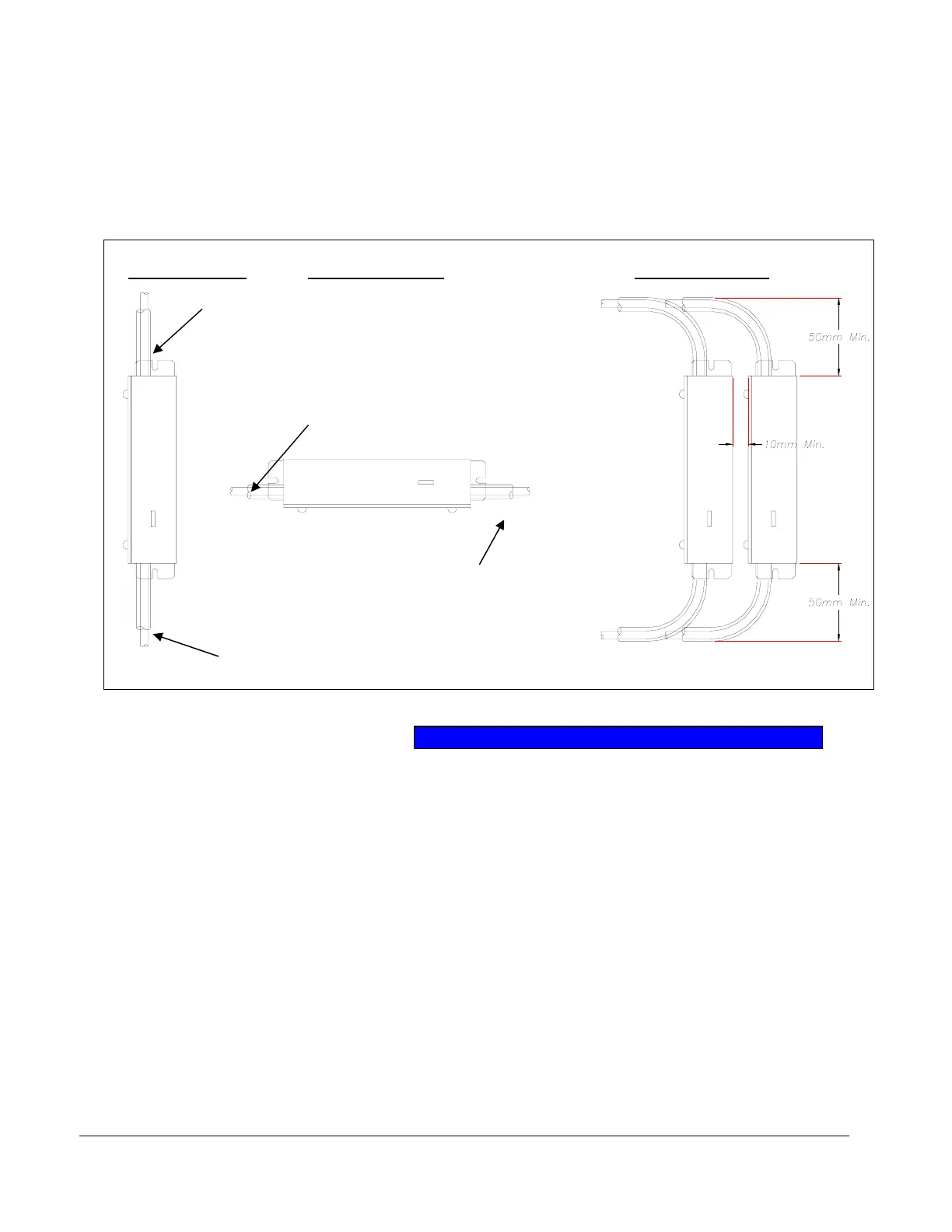

(5) Please use 2 ea of M3 screws to mount amplifiers as per the sketch below. Please leave 10mm

distance or greater between amplifiers, and leave 50mm or greater space for cables:

4.2. Wiring

Please wire with reference to section 3.2.3.

4.2.1. Wiring

(1) The following precautions may help to avoid problems with electrical noise:

① The wires from the Controller to the PLC and noise filter should be as short as possible.

② Power to coils of relays and solenoids should be managed by surge hardware.

③ Separate the wiring from other equipment.

(2) When the Mechatronics Cylinder system is being controlled by 24V I/O:

① Design the system to allow shut off of the 24V line to the actuator in case of “SERVO ALARM”.

② The sequences of power up and down should be as follows:

Vertical mounting

Horizontal mounting

Motor, Encoder cables

Power parallel cable &

Serial cable

Top

Lower

Lower

Top

Motor, Encoder cables

Power parallel cable &

Serial cable

Installation distance

PNP T

e

Loading...

Loading...