. .

Dyadic Systems – Mechatronics Cylinder Manual MF-005500-EN-5/63

1. Summary

The Mechatronics Cylinder consists of a rotary-linear motion transfer mechanism, a stepper motor, an

encoder, and a servo controller. Manufactured by Dyadic Systems, this product can be a replacement for

pneumatic cylinders. Motion is programmed and controlled using Dyadic’s simple interfaces, allowing for a wide

variety of inputs and inter-operability.

1.1. Features

1.1.1 Overcoming weaknesses of Pneumatic Cylinders

(1) Simplifying wiring and related equipment.

(2) Multiple positioning: Easy program for up to 16 motions per axis

(3) Programmable Push Force

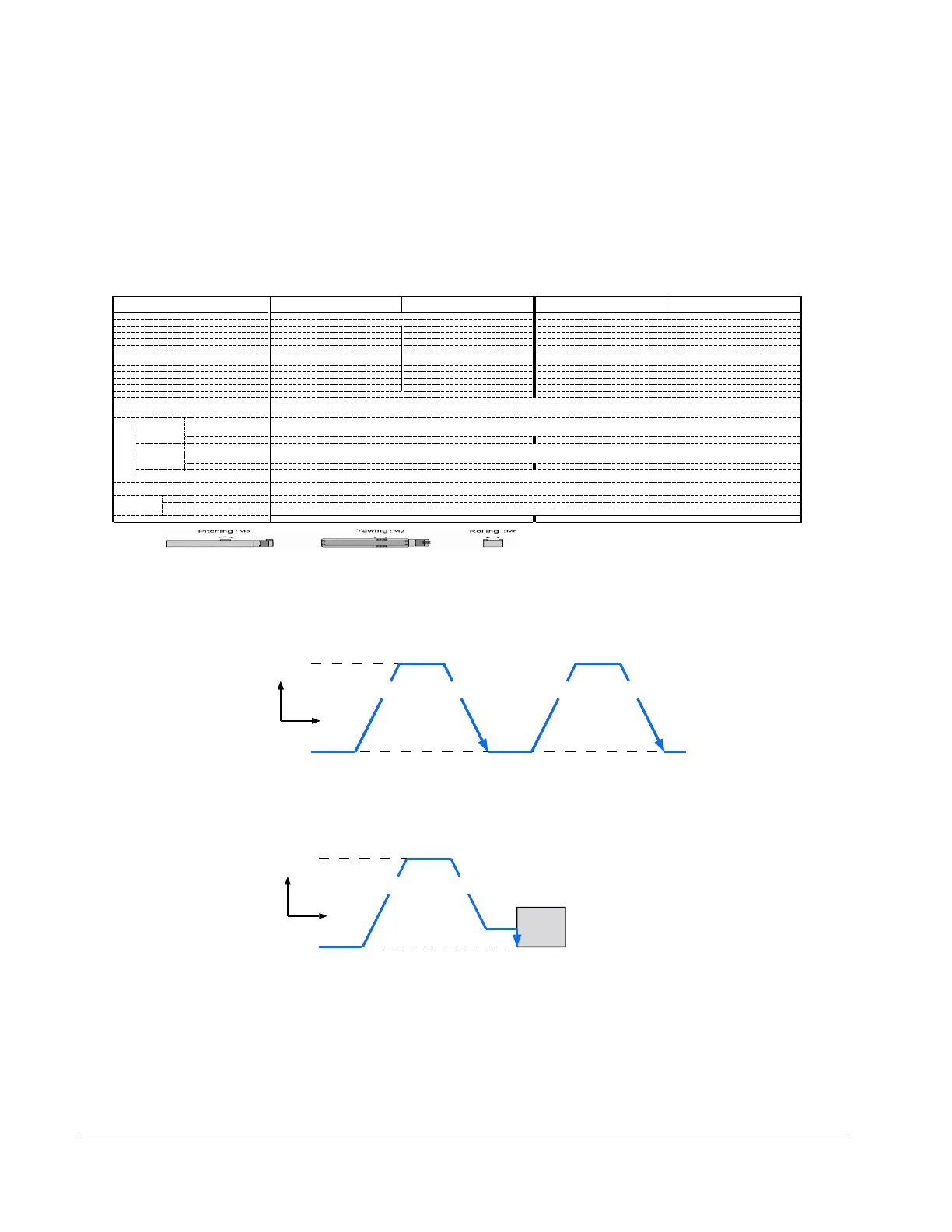

MODEL SCLT4-015

SCLT4-030

SC LT6-025 SCLT6-050

-XXX AS -XXX AS -XXX AB -XXX AB

Am plifier B u ilt-in to a c tu a to r External

S troke (m m ) 50 / 100 / 150 / 200 / 300 / 400 / 500 50 / 100 / 150 / 200 / 300 / 400 / 500 / 600 / 700

M ax. Thrust (N ) / (kgf) 150 / 15 300 / 30 250 / 25 500 / 50

M ax. carriable w t at pw r O N (kg) 1.5 2.5 46

P ush m ode m ax. Thrust (N )/(kgf) 105 / 10.5 210 / 21 175 / 17.5 350 / 35

B all screw lead (m m ) 12 6 12 6

M ax. S peed (m m /s) * note 1 700 (680m m /s for 400 (340m m /s for 600 (500m m /s for 350 (600m m : 340m m /s)

500m m stroke) 500m m stroke) for 700m m stroke) (700m m : 250m m /s)

R epeatability (m m ) ± 0.02 ± 0.02 ± 0.2 ± 0.2

B ackla sh (m m ) 0.1 0.1 0.1 0.1

M ax. H or Load w eight (kg) 5 10 16 30

M ax. vertical load (kg) 1.5 2.5 46

Load m om ent (N m / kgf-cm ) *2 M p=12 / 120, M y=12 / 120, M r= 31 / 310 M p=25.7 / 257, M y=25.7 / 257, M r=58 / 580

P rogram C apacity 16 P ositions

Power Supply D C 24V ± 10% (D rive P ow er m ax. 2.0 A m ps, C ontrol pow er m ax. 0.2A )

Life 3 years after delivery, or 10,000 km operation w hen used w ithin all specs.

P a ra lle l D C 2 4 V ty p e D ig ita l In p u t In te rfa c e

Input N am es P osition select bits (4 bit binary coded decim al: P C 1,P C 2,P C 4,P C 8)

S tart (C S T R ), M ovem ent Interlock (ILK )

Input curren t

M ax. 4m A / port, P N P S tandard M ax. 4m A / port, P N P S tandard

I/O P a ra lle l D C 2 4 V ty p e D ig ita l O u tp u t In te rfa c e

O utput N am es C om pleted P osition N um ber (4bit binary: P M 1,P M 2,P M 4,P M 8) : (S C LT 6 O nly)

H om ed signal (ZFIN ), Z one signal(ZO N E ), A larm (A LM ), P osition com plete (P FIN /IN P )

O utp ut current

M ax. 10m A / port, P N P S tandard M ax. 10m A / port, P N P S tandard

S erial S ignal S erial Interface (C onnector S IO )

+5V , 0V , S + , S -, A S C II P rotocol F reely A vailable

P rotection function O ver speed, M ain pow er over voltage, abnorm al voltage,

O verload, S ensor abnorm al, S ervo abnorm al, E ncoder w ire disconnected

A m bience O perate T em perature 0 ~ 40°C

S torage T em perature -20 ~ 60°C

O pe/S torage H um idity =< 90% R H , non-condensing

W eight (kgs) 1.42/1.53/1.64/1.74/1.96/2.18/2.4 2.7 / 2.9 / 3.1 / 3.3 / 3.7 / 4.1 / 4.5 / 5.0 / 5.4

N o te s : (* 1 ) T y p ic a l d a ta , ( *2 ) T h is is a lo a d th a t th e w t (m k g ) is g e n e ra te d b y th e o v e rh a n g ( L m ) fr o m th e a r rio r s lid e r.

(T he calculation of the load m oe m ent (kgf-cm ) is: m (kg) x L (cm ) < M p, M y, M r)

The actual m om ent will be com binations of those m om ents (M p, P y, M r).

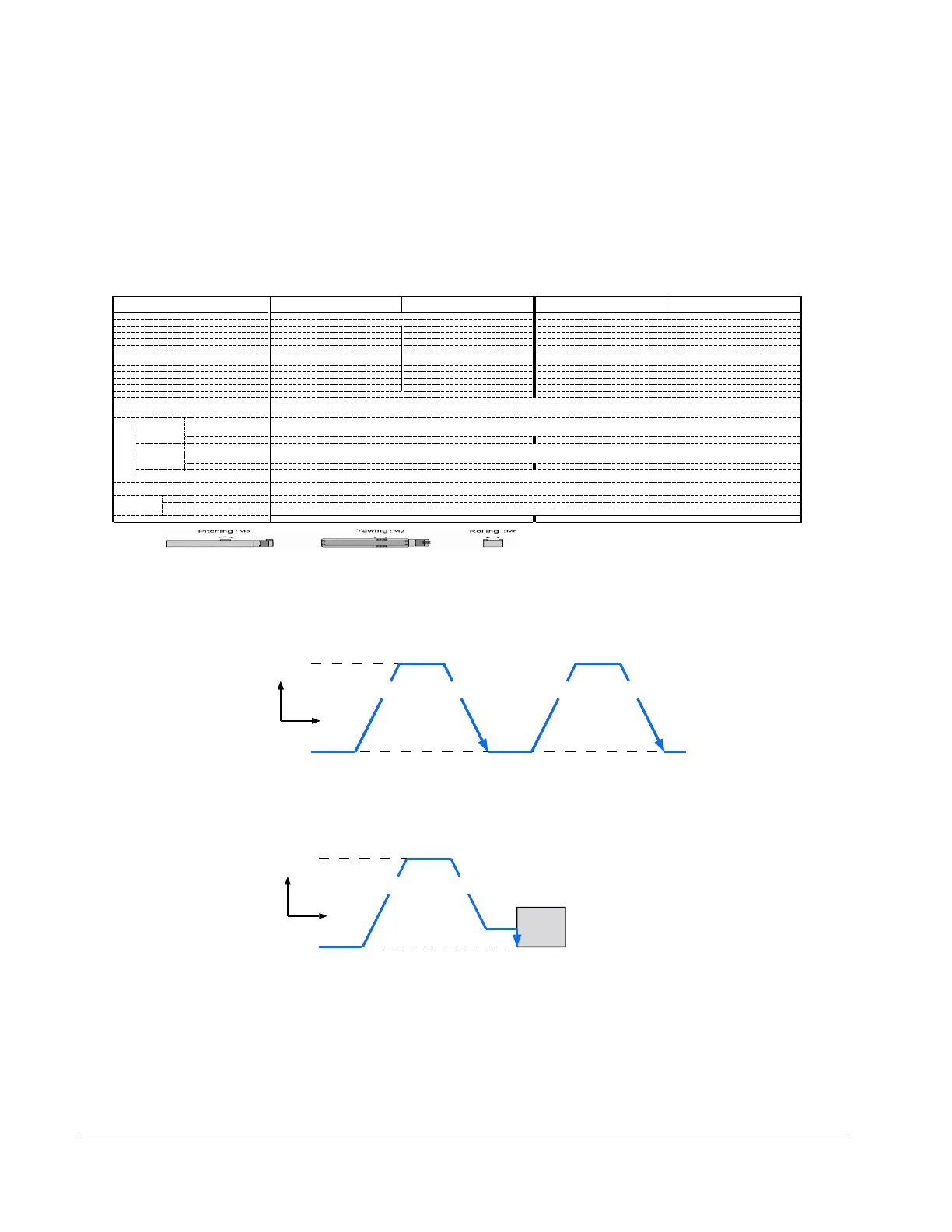

cceleration Deceleration

Programmed

Speed

Stop

condition

Speed

Time

cceleration Deceleration

Work

Programmed

Speed

cceleration Deceleration

Stop

Position

Push

Movement

Speed

Stop

condition

Time

Loading...

Loading...