Section 1 - THEORY OF OPERATION

The Dynamatic® Eddy Current drive system consists of a prime mover (AC induction motor), an AC motor

starter (optional and not provided), the Eddy Current coupling, a speed feedback device (tachometer

generator) and a controller with an operator interface.

The AC motor is started under no load and allowed to reach full speed before the controller is energized

(motor starter not included). The output of the control is determined by reference setting and feedback

magnitude with drive speed and torque being based on the operational mode and load requirements.

Speed control mode with tachometer feedback will regulate within 0.5% of set speed, while

approximately 5% regulation is possible in torque mode using the internal clutch current loop as feedback.

Preset speeds, jog, thread, and external reference inputs are available as standard parameter selections

with the EC 2000 control.

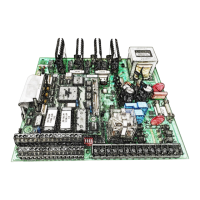

The EC 2000 uses digital technology to provide a flexible, low noise control for today’s high tech industrial

environment. It provides setup and programming via a keypad with a user friendly alphanumeric display;

drive parameters may be programmed and displayed by the customer to activate the many built-in

features.

Figure 1: Eddy Current Drive & Control Block Diagram

Loading...

Loading...