22 CA 150 M150EN2

3

2

1

EVERY 1000 OPERATING HOURS (Every six months)

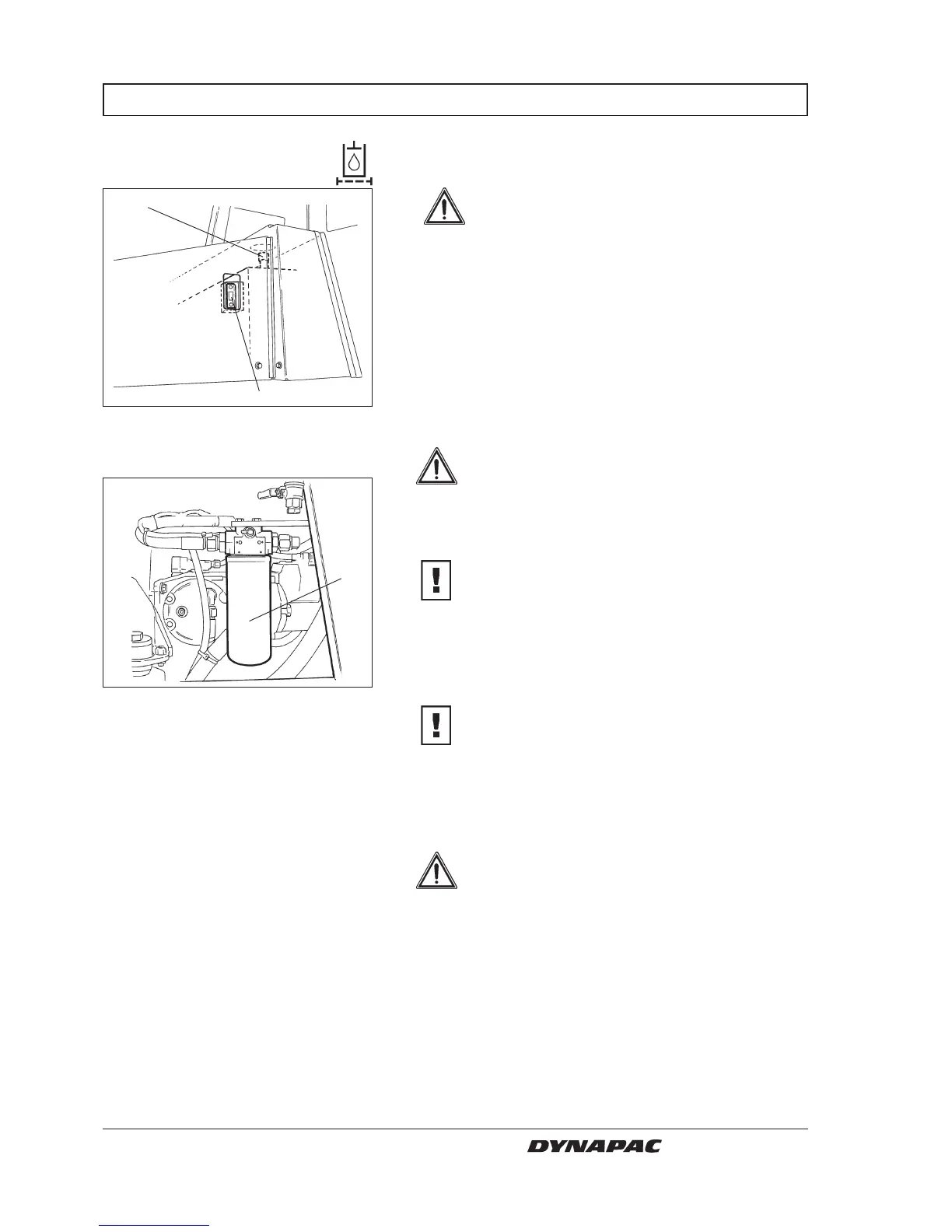

Fig. 28 Hydraulic reservoir

2. Filler cap/Breather filter

3. Sight glass

Hydraulic filter

– Replacement

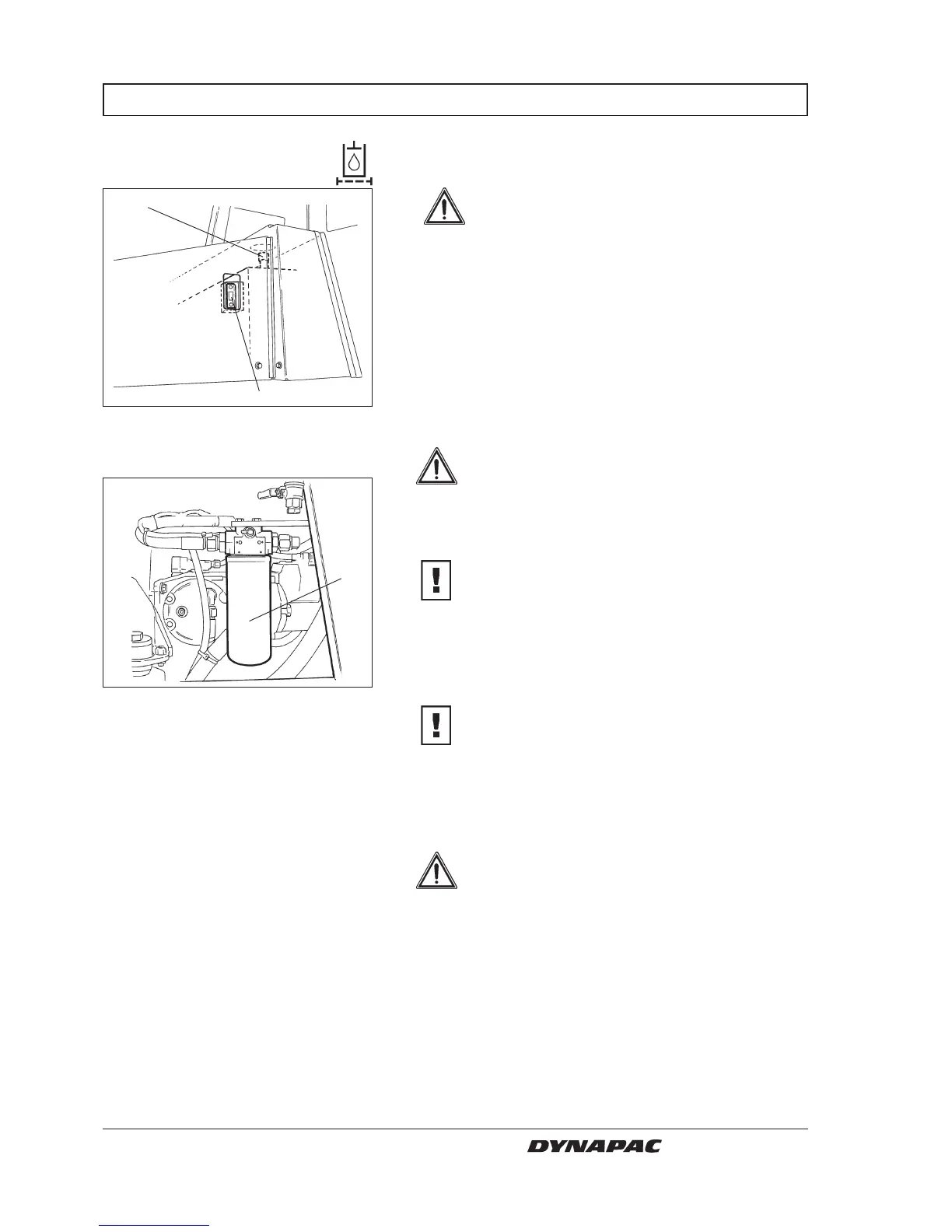

Fig. 29 Engine compartment

1. Hydraulic filter (x1)

Place the roller on a level base. The engine

must be switched off and the parking brake

applied for all checking and adjustments

on the roller unless stated otherwise.

Loosen the cap/breather filter (2) on top of the reservoir

to relieve any excess pressure inside.

Ensure that the breather filter (2) is not clogged, air

must have unobstructed passage through the cap in

both directions.

If clogged in either direction, clean with a little diesel oil

and blow with compressed air until free passage is

assured, or replace the cap with a new one.

Wear protective goggles when working

with compressed air.

Clean thoroughly round the hydraulic filter. Remove the

hydraulic filter (1) and scrap it. They are of the

expendable type and cannot be cleaned.

Ensure that the old sealing ring is not left on

the filter holder. Leakage may otherwise occur

between the new and the old seals.

Thoroughly clean the sealing surface of the filter holder.

Apply a thin coat of fresh hydraulic fluid on the new

filter seal.

First, screw on until the filter seal lies against

the filter holder. Then screw a further half turn.

Do not tighten the filter too hard, which could

damage the gasket.

Start the engine and ensure that there is no leakage of

hydraulic fluid from the filter. Check the fluid level in the

sight glass (3) and top off as required.

Ensure that ventilation (extraction) is

adequate if the engine is run indoors.

Risk of carbon monoxide poisoning.

WARNING

CAUTION

WARNING

CAUTION

WARNING

Loading...

Loading...