M-Max Series adjustable frequency drive

MN04020002E

For more information visit: www.eaton.com 13

February 2010

Operation

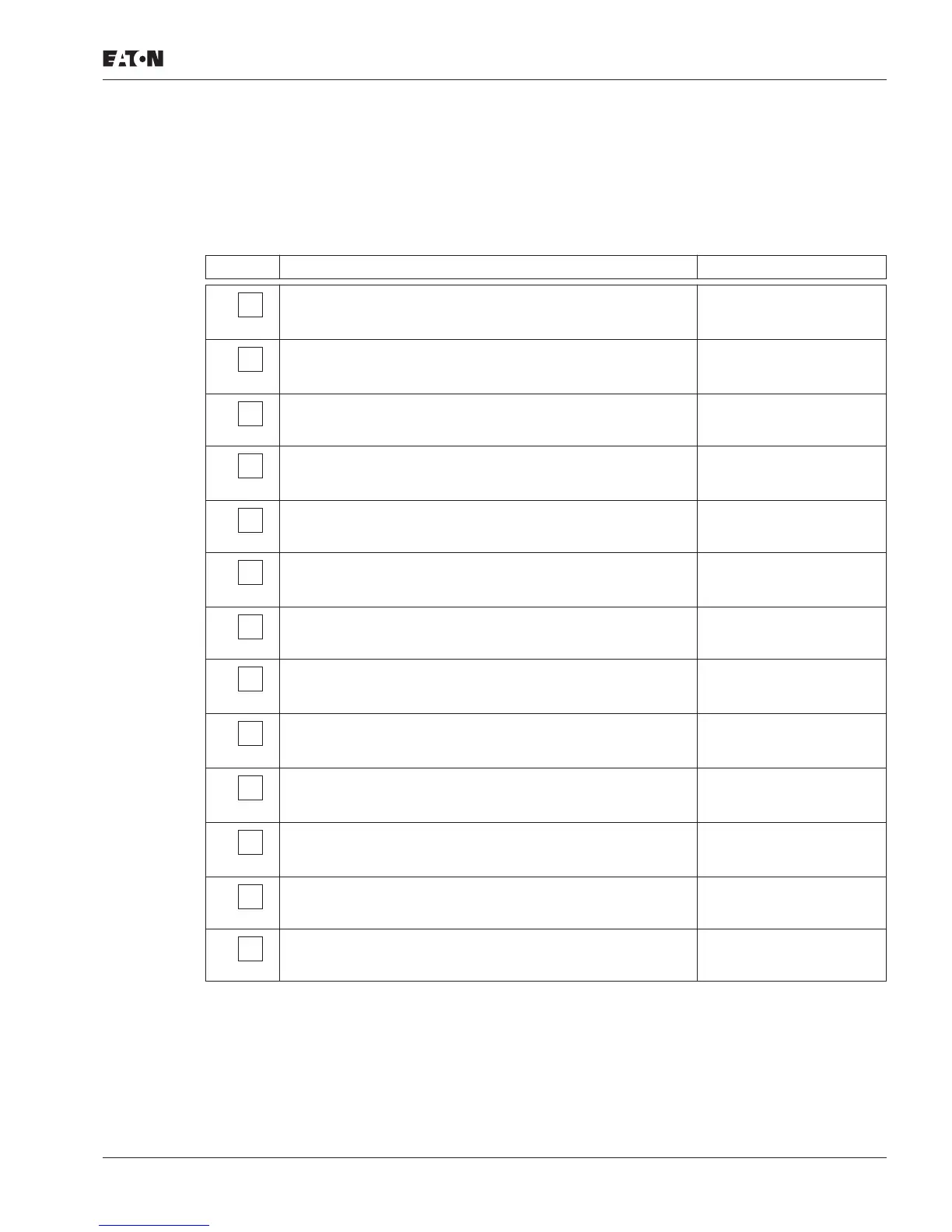

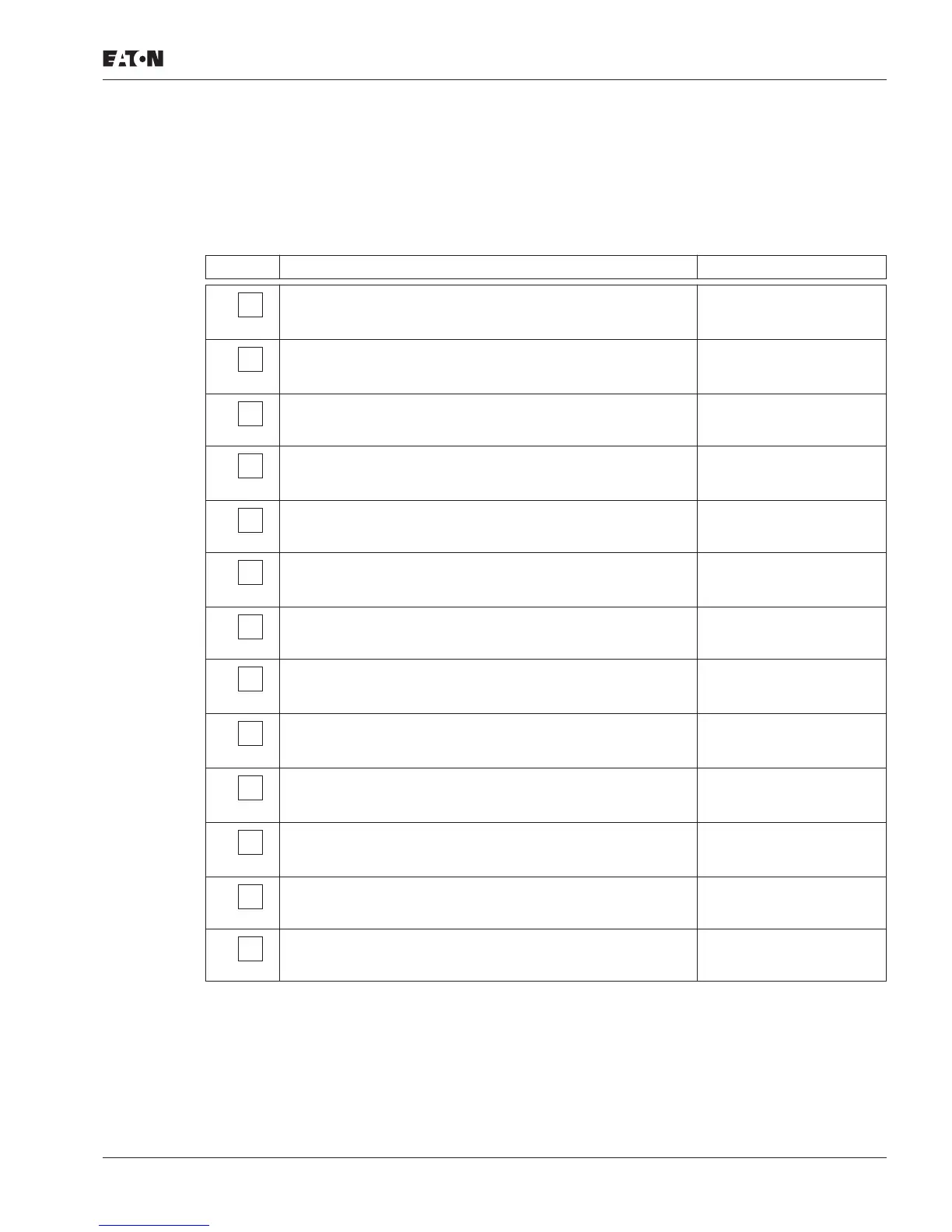

Checklist for commissioning

Before placing the adjustable frequency drive into operation, make sure to check the following

(checklist)

:

No. Activity Note

1 Installation and wiring have been carried out in accordance

with the corresponding installation instructions

( IL04020001E).

2 All wiring and line section leftovers, as well as all the tools

used, have been removed from the adjustable frequency

drive’s proximity.

3 All terminals in the power section and in the control section

were tightened with the specified torque.

4 The lines connected to the output terminals of the adjustable

frequency drive (U/T1, V/T2, W/T3, R+, R–) are not short-

circuited and are not connected to ground (PE).

5 The adjustable frequency drive has been earthed

properly (PE).

6 All electrical terminals in the power section (L1, L2/N, L3, U/T1,

V/T2, W/T3, R+, R–, PE) were implemented properly and were

designed in line with the corresponding requirements.

7 Each single-phase of the supply voltage (L1, L2, L3) is

protected with a fuse.

8 The adjustable frequency drive and the motor have been

adjusted for the corresponding line voltage (

section “Rated

operational data on the nameplate,” Page 4).

9 The quality and volume of cooling air are in line with the

environmental conditions required for the adjustable

frequency drive.

10 All connected control lines comply with the corresponding

stop conditions (e.g., switch in OFF position and set point

value = zero).

11 The parameters that were preset at the factory have been

checked with the list of parameters (

section “List of

parameters,” Page 30).

12 The effective direction of a coupled machine will allow the

motor to start.

13 All emergency switching off functions and safety functions are

in an appropriate condition.

Loading...

Loading...