ECP2010 / ECP2010H

52 / 68

Caution: Watch washing heads and all connections during run-in for any leakage.

Correct every untightness!

In menu item Menu/Service/Parts replacement/Seals tick the seal that has been

replaced.

L PUMPING – left working head seal

L WASHING – left washing head seal

R PUMPING – right auxiliary head seal

R WASHING – right washing head seal

Continue by choosing CONTINUE. Press ENTER for confirming seal replacement. This way

operation counters zeroize in Menu/Info/Parts/Seals.

6.7.1.2. Check Valves

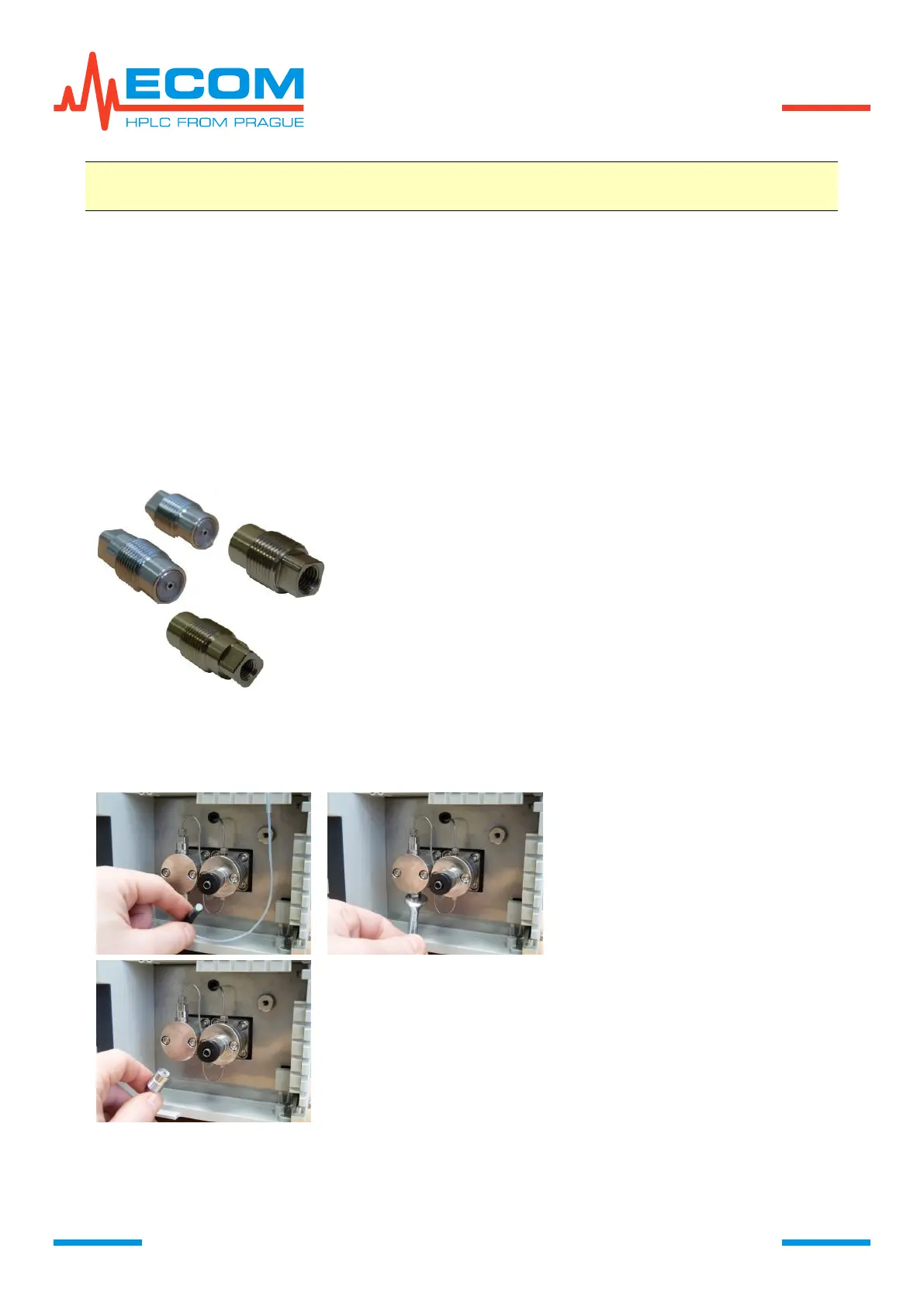

The basic elements of a check valves are precies ball and

seat. By the liquid flow the ball is pressed into the seat and

seals it. Considering high pressures in the pump, any slight

impurity stuck on the ball surface, or the seat, results in

pressure fluctuation, or it is not possible to start the pump. If

this issue is not solved by repeated purge, it is necessary to

replace, or clean the check valves.

There are two types of check valves – inlet and outlet. Both

types have fixed valve mounted directly in the holder.

Therefore, it is necessary to replace the entire part. Inlet check

valve is shorter then outlet and the inner part of the holder

designated to mount the inlet tubing has flat bottom (upper

picture on left). The outlet valve is longer than inlet and inner

part of the holder for mounting capillary is conical (lower picture

on left).

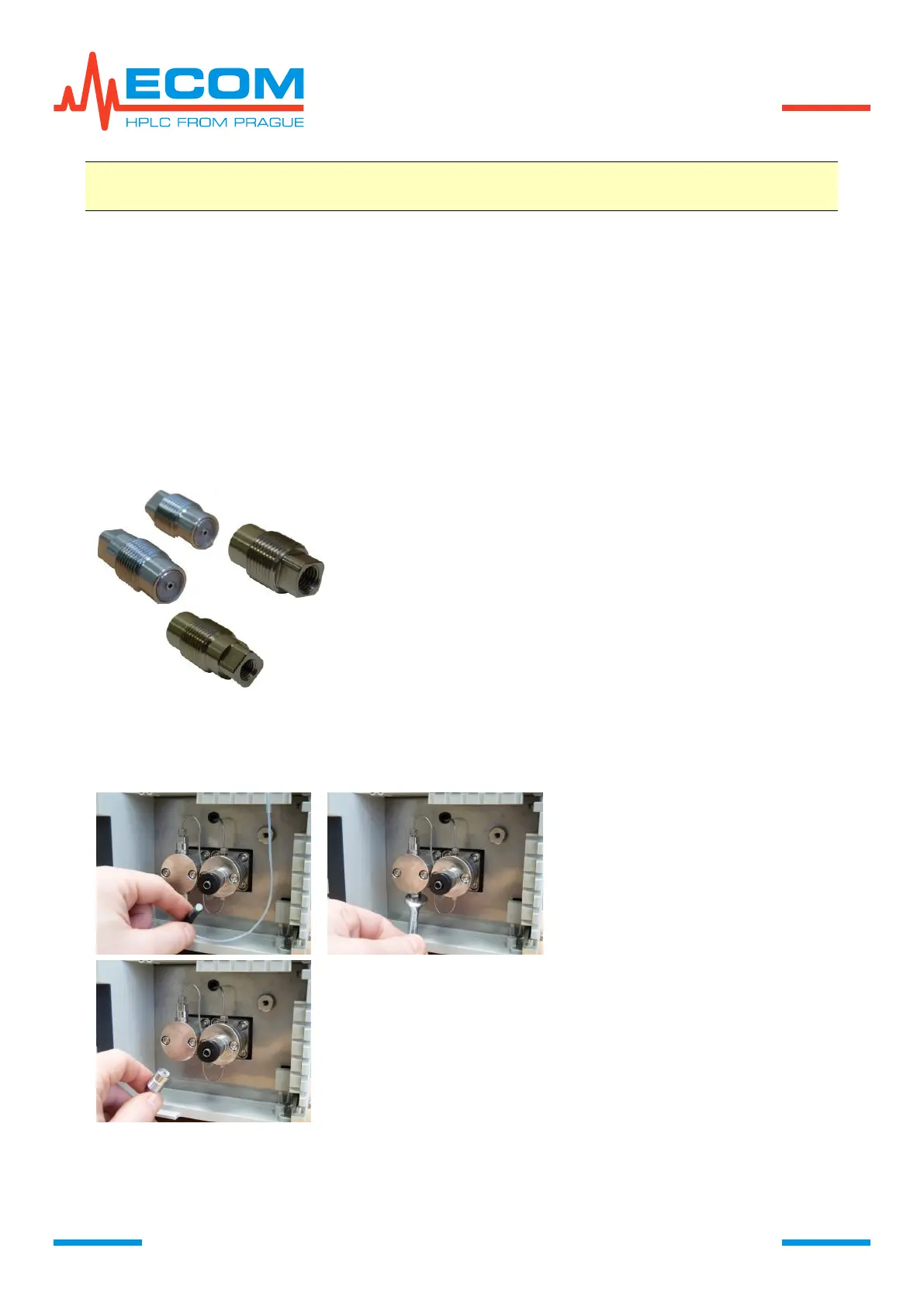

Disconnect the unit from power

source!!!

Disconnect inlet tubing.

To exchange inlet check valve,

unscrew the holder of check valve

using a side wrench 5/16" (8 mm).

Loading...

Loading...