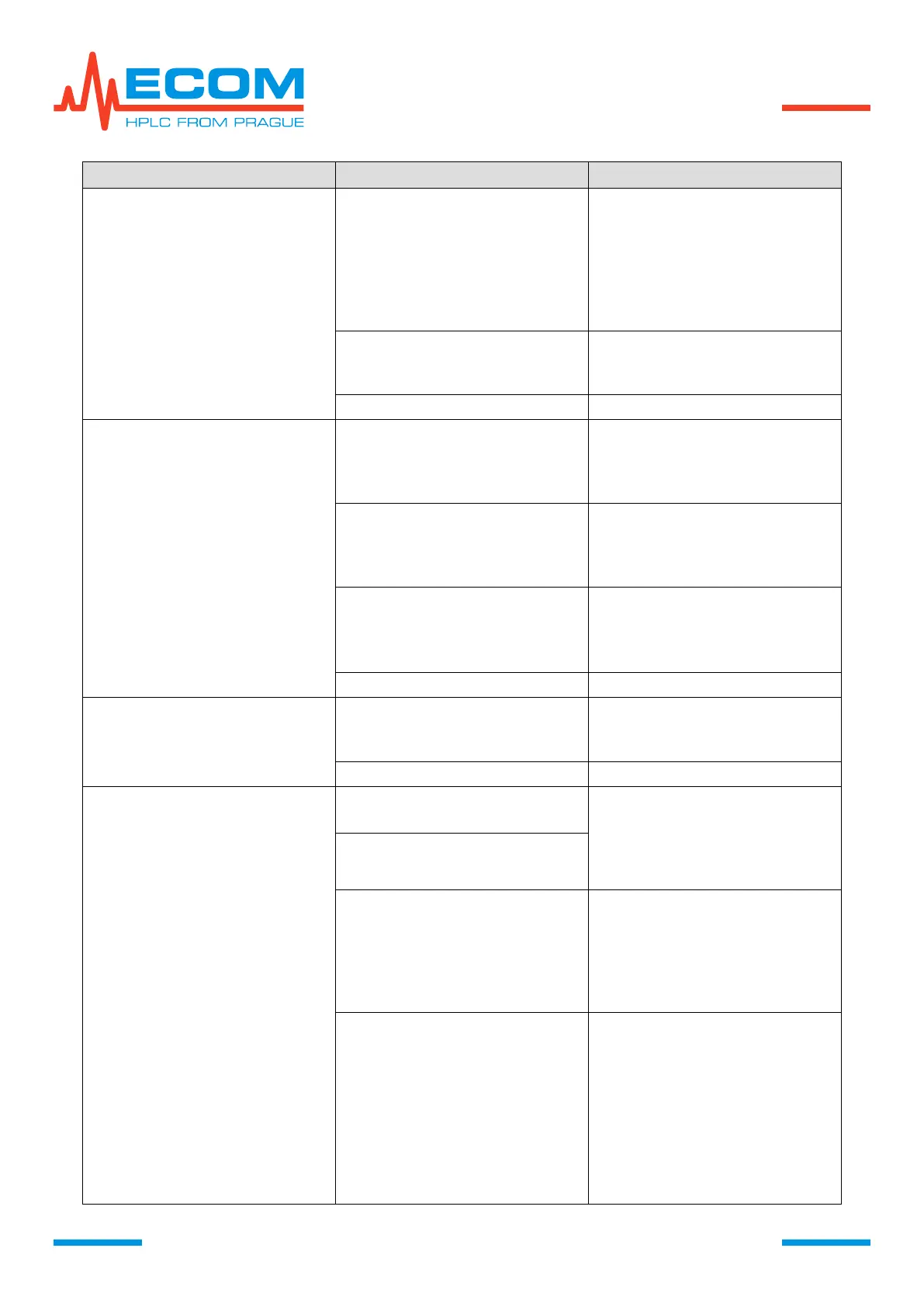

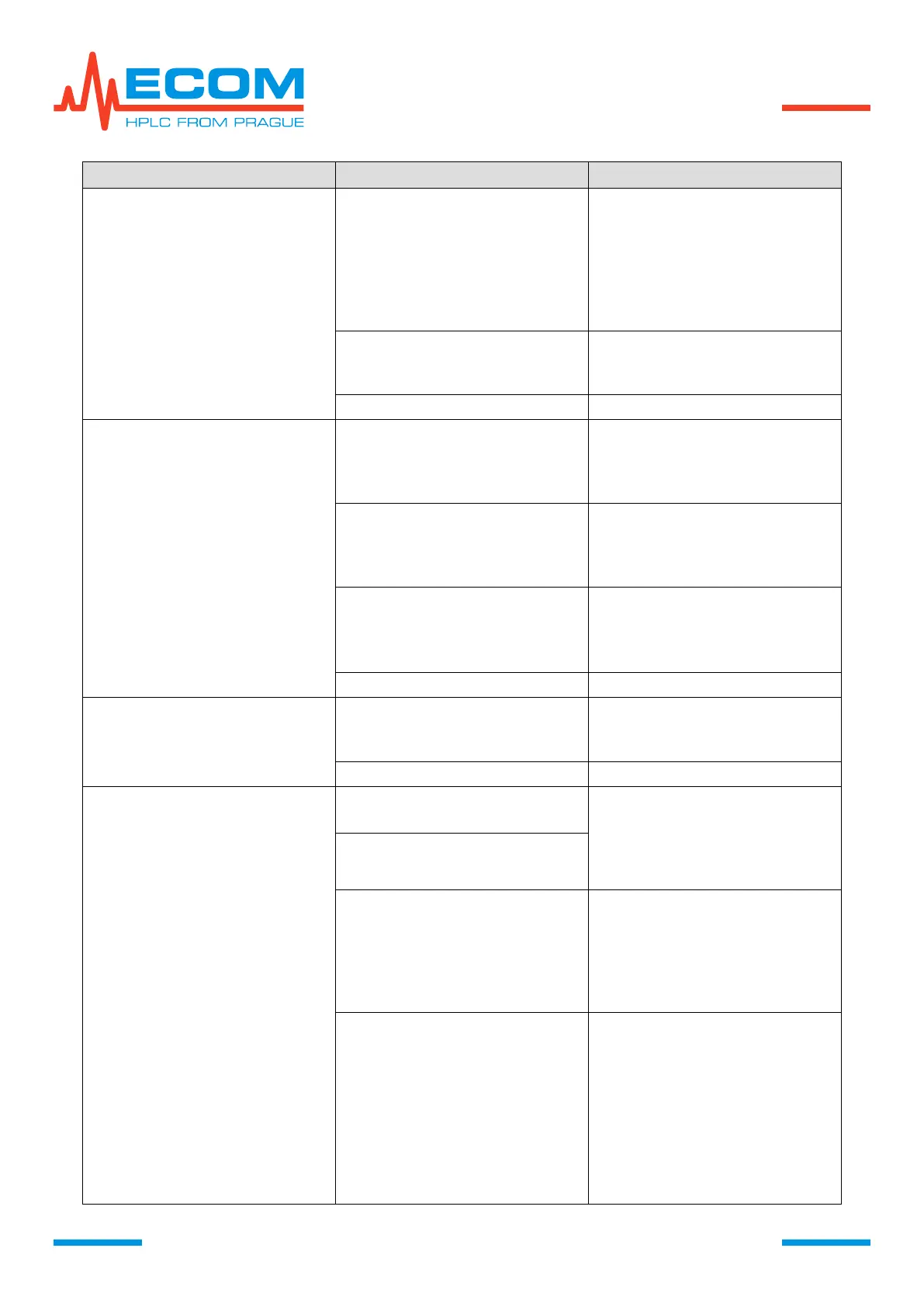

ECP2010 / ECP2010H

60 / 68

Damaged seal – esp. when

using solvents as Acetonitrile.

It may seem like that bubbles

are formed inside the pumping

system, it is convenient to

exclude other source of

bubbles using degasser.

Try to replace seals

(See 6.7.1.1).

The pump is not run-in

properly after seals

replacement.

Run-in the pump under optimal

conditions (see 6.7.1.1).

Flowrate is lower then set

value.

Problems with lower flow rate

occur and usually relate to

problems with pressure

stability – see solution above.

Solution agents with very high

or very low viscosity may

cause these problems. As well

as not degassed solvents.

After eliminating above

mentioned reasons, proceed

automatical calibration FLOW

AUTO (see 6.7.2.2).

Motor works hardly/loudly,

there isn’t indicated any

pressure and flow rate is low

or none.

Clogged frit of outlet valve.

Only if check valves with frit

are used.

Check the frit, try to clean it or

replace the check valve.

Electronic/mechanic failure.

Reporting of errors and

warnings (Wxx, Exx)

E24 – PRESSURE PEAK

OVER SAFETY LIMIT!

Operating error. Locate and

eliminate reason for pressure

escalation – stuck column,

clogged frit behind the unit or

other, above mentioned.

E41 – PRESSURE OVER

HIGH LIMIT

E28 – PRESSURE UNDER

LOW LIMIT!

Operating error. Locate and

eliminate reason for pressure

suppression – leakage from

the system (leaking

purge/degass valve and other,

above mentioned)

W4, E29 – PUMP LEAKAGE!

REMOVE ALL LEAKS. DRY

UP SENSOR AND WAIT

FOR 60 s TO UPDATE.

Reported according to setting

in 6.2.7.

Operating error.

Eliminate source of leaking

and dry up surroundings of

sensor (see 6.2.7)

Loading...

Loading...