HiVol 3000 User Manual 1.7 Maintenance

63

6

6

6

M

M

M

a

a

a

i

i

i

n

n

n

t

t

t

e

e

e

n

n

n

a

a

a

n

n

n

c

c

c

e

e

e

Regular maintenance and inspections should be performed on the HiVol and

associated equipment. Damage to the HiVol and electrical cord may jeopardise safety

and cause potential fire hazards. Periodic statutory electrical safety checks are also

required in most countries.

The HiVol sampler will normally spend its entire lifetime in the field exposed to the

weather.

It is therefore important that the equipment is regularly inspected and maintained as

this will assist in obtaining high quality data and reliable performance.

The frequency of cleaning and maintenance will depend on the site location and the

sampling sequence selected for monitoring.

It is recommended that a plan is developed for regular maintenance and that any

maintenance is recorded in the instrument log-book for the HiVol sampler.

A typical maintenance procedure for the Ecotech HiVol 3000 is contained in Table 1.

Note: The high volume sampler motor is

equipped with sealed groove ball bearings,

which do not need lubrication. The grease

filling is sufficient for the whole service life of

the bearings.

6.1 Maintenance tools

To perform general maintenance on the HiVol 3000 the user will be required to carry

the following equipment:

• Cloth

• Grease

• Dow Silicone Slipicone Release Spray (#316)

• Manometer

• #2 Philips-head screwdriver

• Knife

• Orifice plate

• Temperature and pressure gauges

6.2 Maintenance schedule

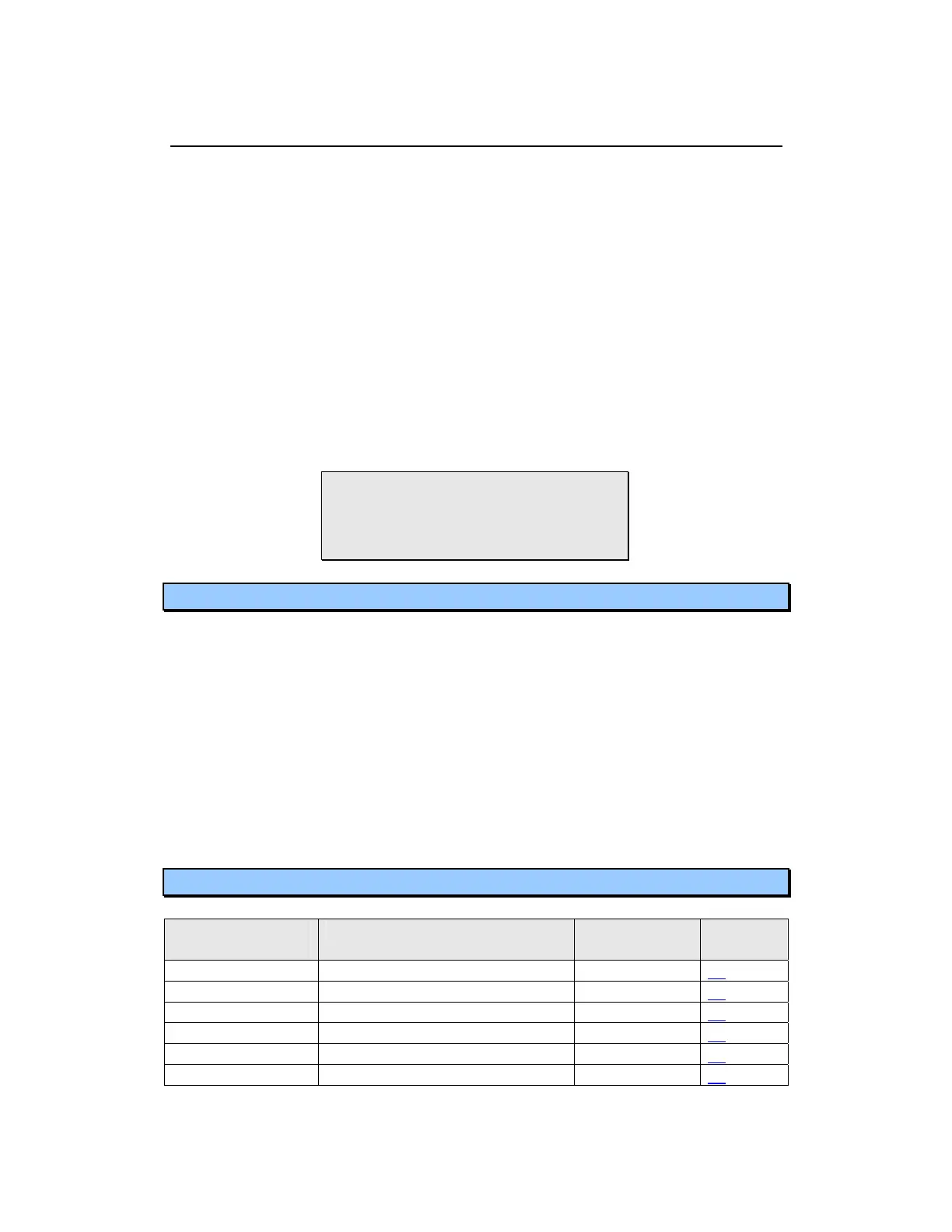

Table 1 Maintenance Schedule

Interval

(samples)*

Item Procedure Page

Weekly General Sampler components Check 64

Weekly Automatic Flow Check 64

Weekly Cassette Clean 64

Weekly SSI (PM

10

or PM

2.5

) Clean/Regrease 64

As Needed Pressure Sensor Adjustment 67

As Needed Pressure Sensor Replacement 67

* Suggested intervals for maintenance procedure may vary with sampling intensity and environmental

conditions.

Loading...

Loading...