HiVol 3000 User Manual 1.7 Maintenance

69

6.3.6.2 Refitting

1. Refit components in the reverse of the removal sequence. Note the following

points:

2.

When replacing the flow sensor , push the tubing against the fittings to

ensure a good seal.

3.

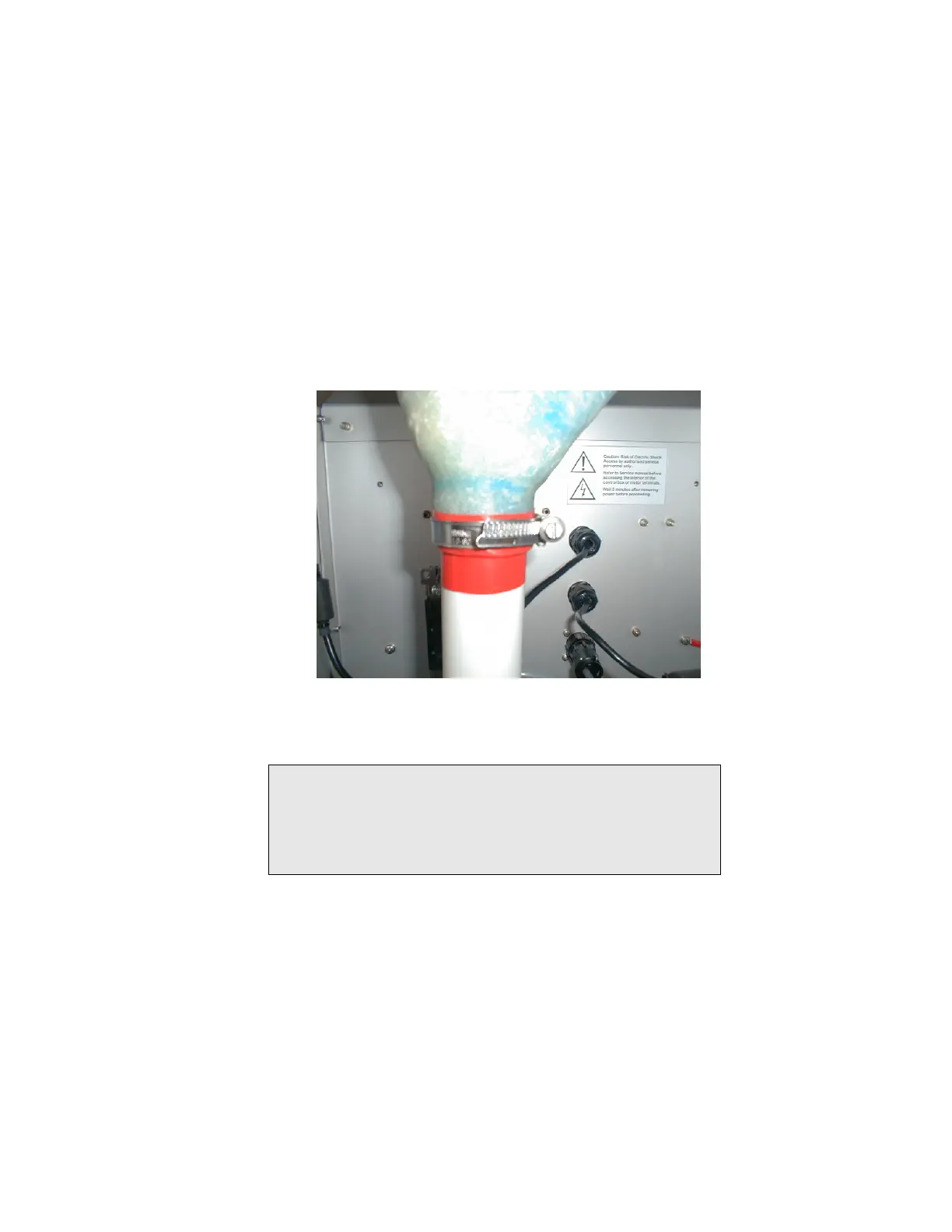

If necessary, apply good quality electrical insulation tape to the coupling

between the Inlet pipe and the Inlet Funnel. Start with the tape around the pipe

(at least 2 full turns) then continue to wrap the tape at least 2 full turns around

the join, and finally 2 full turns around the Inlet Funnel, stretching the tape

slightly as you go to ensure a good seal. Tighten the Pipe Clamp on the Inlet

Funnel. The tape provides the seal and the Pipe Clamp ensures the tape stays

in position. Do not over-tighten the pipe clamp.

4. Ensure all seals are good, then recalibrate the HiVol according to the

procedure in the User manual. Depending on the Zero Flow flow voltage

adjustment, the Flow Voltages during calibration should be in the order of:

60 m

3

/hour: 1.8-2.4V

70 m

3

/hour: 2.2-2.8V

80 m

3

/hour: 2.5-3.3V

. If not, check for leaks.

5. Finally replace the rear panel.

6.

Test the sampler for correct operation.

7.

If necessary, take the HiVol out of Manual mode. Go to the Main

Menu>Manual menu, then set Manual Mode to NO. Hit Exit to return to the

Main screen.

Loading...

Loading...