SOI/DT 2010-03 dmm 50/78 599 72 84-41

11.3.2 Operating principle of the flowmeter

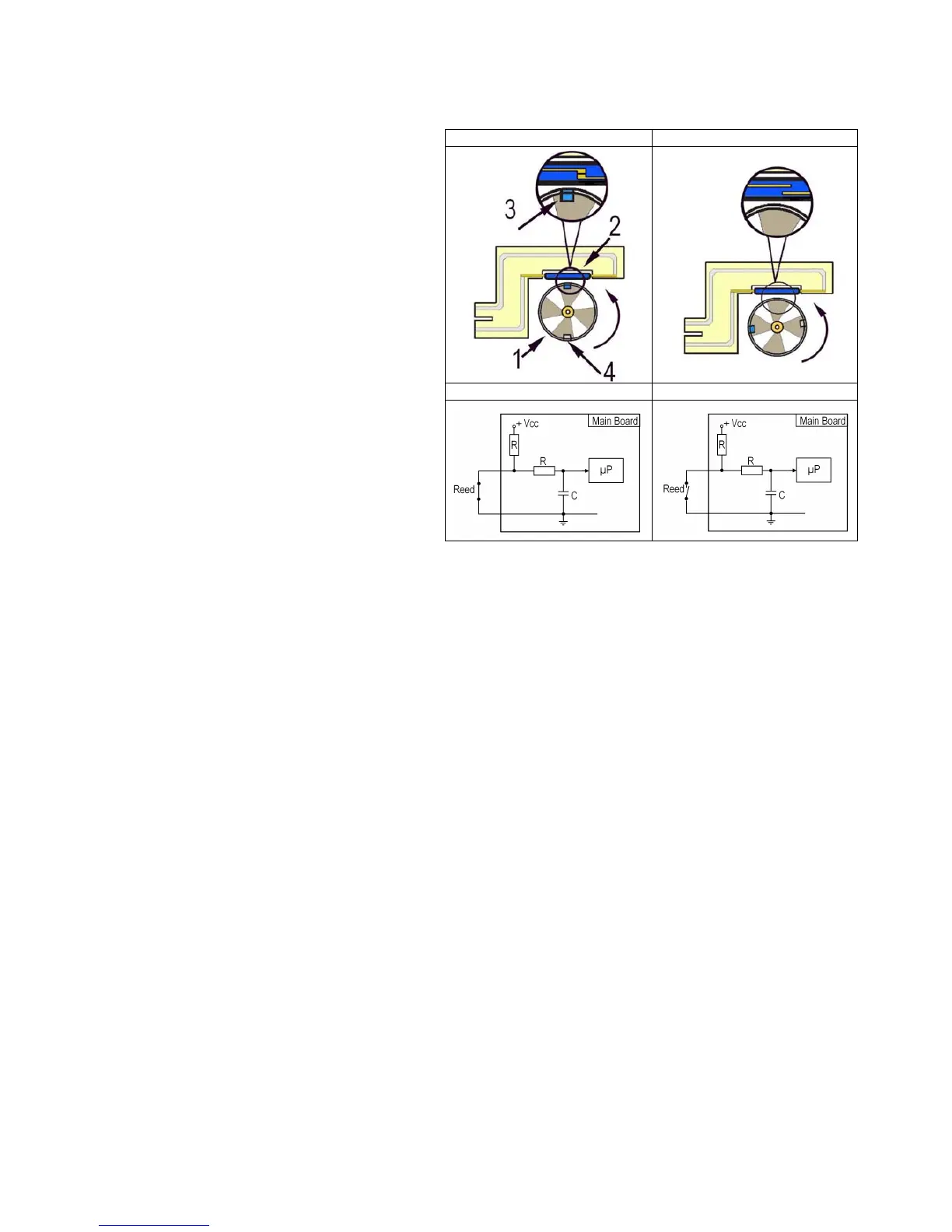

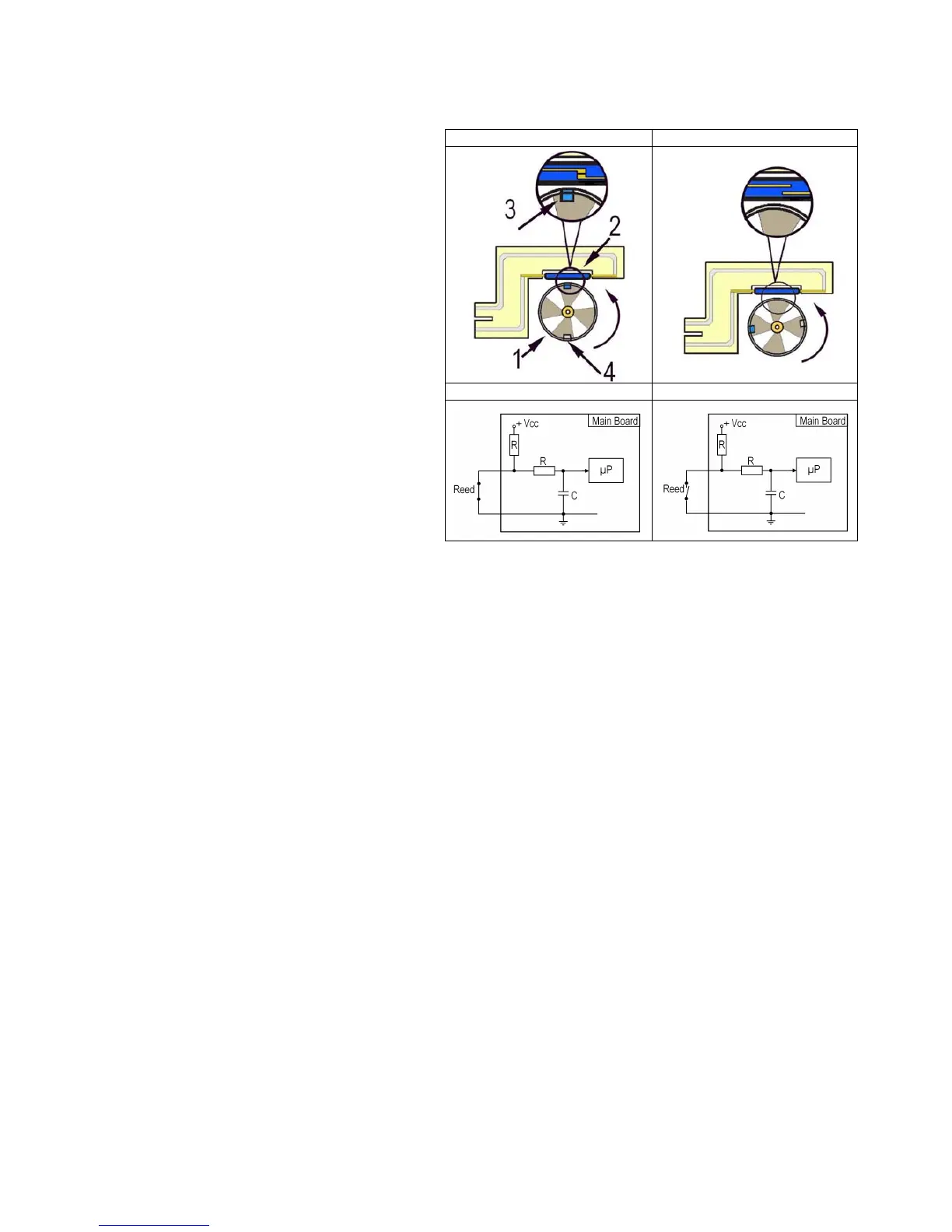

The main components of the flowmeter are:

1 – Turbine (with magnet and counterweight

mounted on the outside)

2 – Reed contact (normally open)

3 - Magnet

4 - Counterweight

Water entering the solenoid valve rotates the turbine (1) and magnet (3), which passes in front of the Reed

contact (2), thus closing it. As this contact opens and closes, it generates pulses at a frequency that depends on

the water flow rate).

The turbine completes 230 revolutions for each litre of water. The operating range of the flow sensor is 0.2÷10

bar.

Using the signal it receives, the micro-processor can calculate the number of litres of water passing through the

solenoid valve.

Mechanical jamming of the solenoid valve

The solenoid valve may jam open without being actuated (which will cause flooding if the pressure switch

controlling the water level does not trip). If this occurs, the electronic control system (which continuously

monitors the flow sensor) will lock the door, start the drain pump and display an ALARM simultaneously.

Low water pressure

If the flow sensor does not generate a signal during the water fill phases, even though power is being supplied

to the solenoid valve, the cause of this condition may be a closed water tap or clogged filter on the solenoid

valve (with ensuing low water pressure). If this occurs, only a WARNING will be displayed and the cycle will

continue for five minutes, after which time an ALARM will be signalled.

The condensation solenoid valve operates during the drying phase on washer-dryers. The alarm is disabled

because the amount of water is very small.

Closed contact Open contact

Signal 0 Signal 1

Loading...

Loading...