SOI/DT 2010-03 dmm 58/78 599 72 84-41

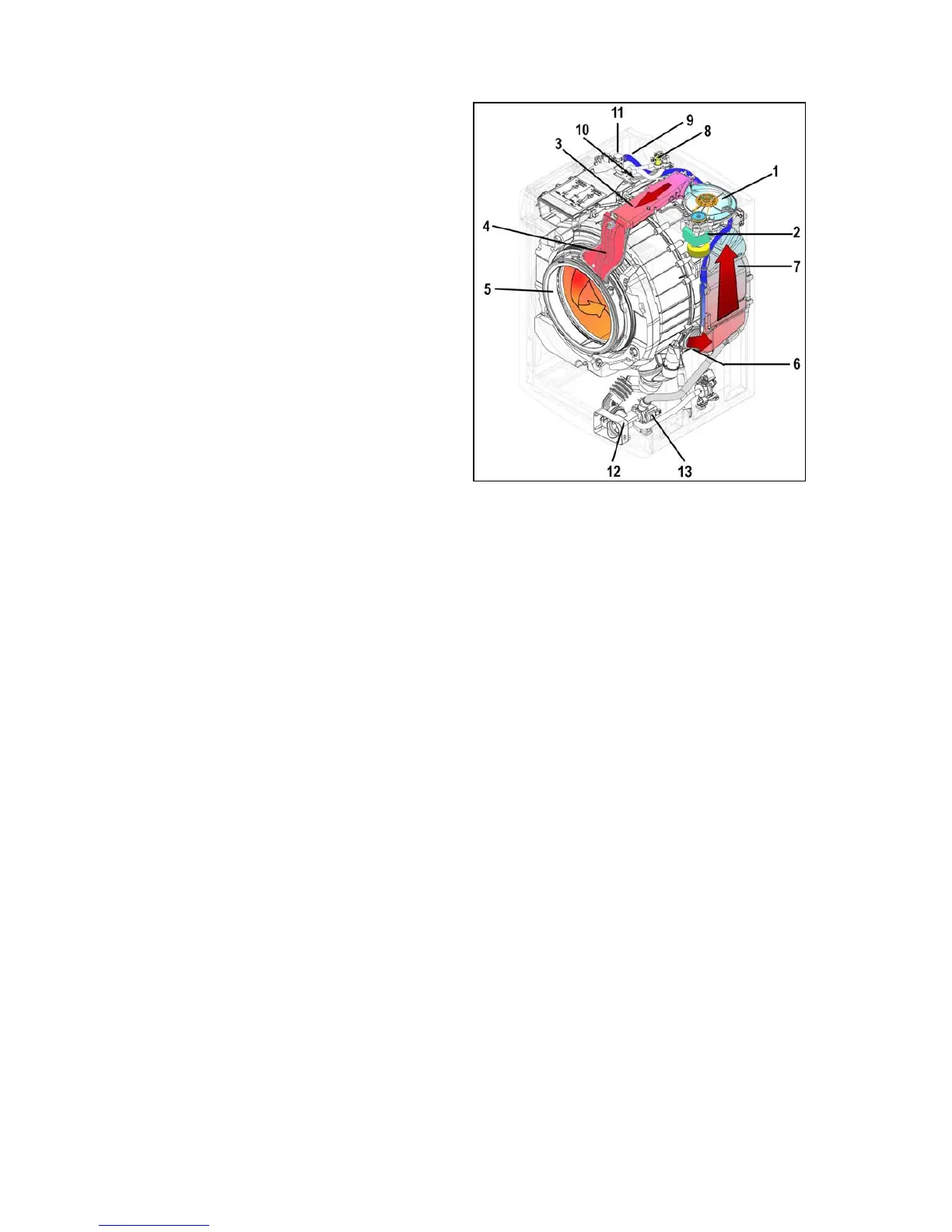

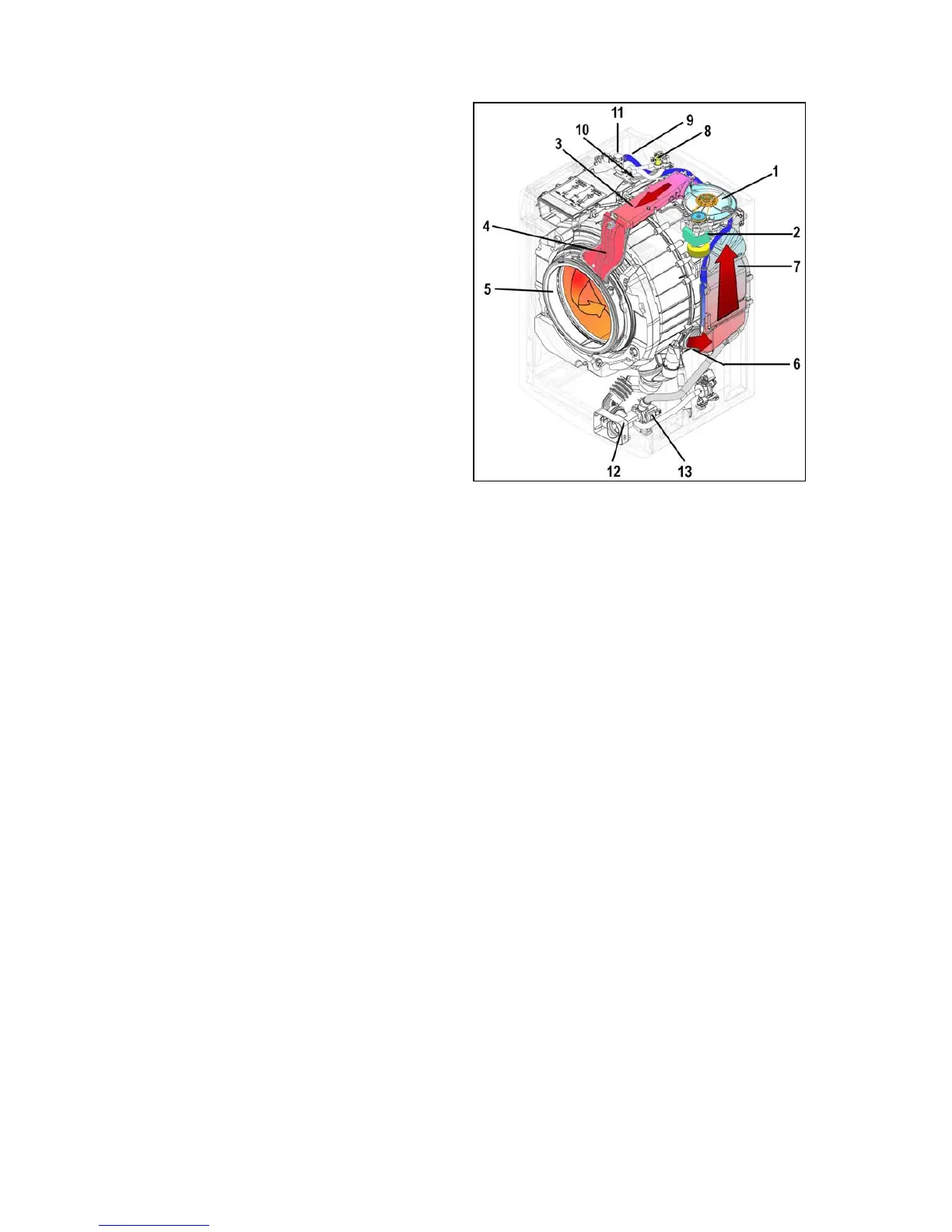

12 DRYING CIRCUIT

1. Fan

2. Fan motor

3. Heating element casing

4. Conduit

5. Bellow seal

6. Tub-condenser sleeve

7. Drying condenser

8. Solenoid valve

9. Condensation intake tube and steam vent

tube

10. Solenoid valve-air break tube

11. Coupling (Air-break)

12. Filter body

13. Drain pump

Automatic drying cycles: the drying time is controlled by the micro-processor so that the desired degree of

drying is achieved.

The drying cycle can be performed at the end of the washing cycle, or as a separate programme.

Three types of drying can be selected:

extra dry

wardrobe dry

iron dry

Time-controlled cycle: The drying time is selected by the user (max. 130 minutes for cotton and synthetic

fabrics).

Cooling: a cooling cycle is performed at the end of every drying cycle.

Anti-crease: after the cooling phase, a 10-minute anti-crease phase is performed

The drying heating elements are powered directly by the main PCB via two relays.

In the cycles for synthetic fabrics, the drying is performed with only one heating element (half power); in the

cotton - linen cycles both heating elements are powered (full power).

The fan motor is powered via a relay; the condensation solenoid valve is powered by a triac.

The wash of the condenser occurs at the beginning of the last rinse.

Loading...

Loading...