remove heavy material from the conveyor and

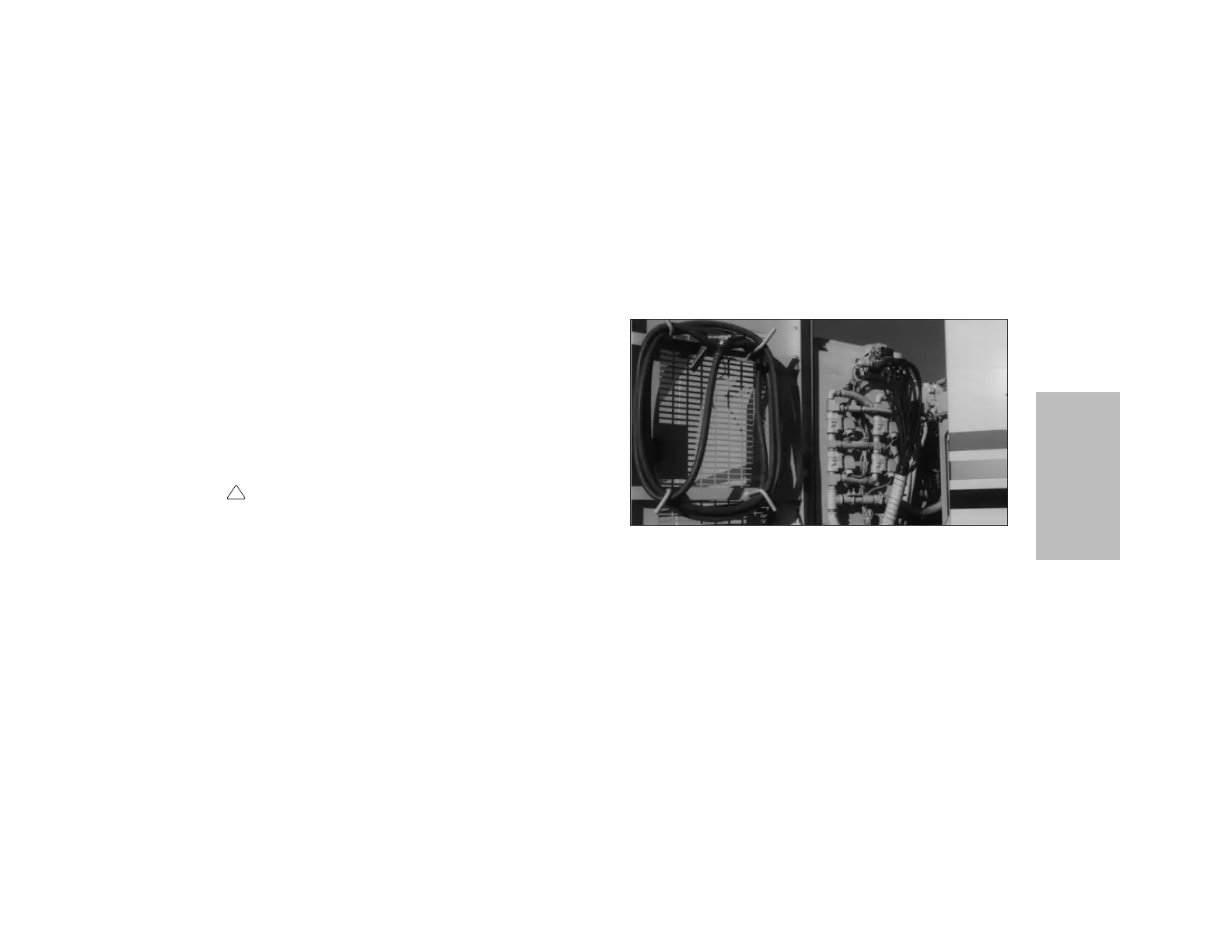

conveyor deflectors. Turn on the lower roller

flush valve (Figure SP-18), located below the

washdown hose quick disconnect coupling.

5. Periodically reverse the conveyor (for no more

than 30 seconds) to dislodge material between

the lower roller and the edge of the scraper bar.

6.

Stop conveyor rotation and return the main broom

and conveyor to transport mode. Return the lower

roller flush valve to its original position

.

DANGER

Falling hopper can cause severe injury or

death. Safety Support must be in position

before anyone goes under hopper.

7.

Tilt the hopper using Hopper dump (Figure SP-1,

#28) and install the Safety Support bar (Figure

SP-15, 16)

.

8. With the conveyor running, use a high pressure

water hose (connected to a hydrant or other

high volume source) to flush the conveyor and

belt backing plate. If a high pressure hose is

not available, use the sweeper’s washdown hose

(Figure SP-19).

9. Flush out the hopper, all undercarriage parts,

side broom(s), and dirt shoes.

10. Use a high pressure hose to dislodge material

between the lower roller and the edge of the

scraper bar. Flush the lower roller from both

sides of the sweeper.

Loading...

Loading...