Note

Replacing the O-rings at this point minimizes the chances of damaging the transducer by

dropping it.

6. Apply a small amount of nickel anti-seize (N.A.S.) compound (P/N 2-9-9960-134) to

the outer threads of the transducer holder (see Figure 3-5).

7. 7. Carefully install the transducer holder assembly into the transducer mount. Make

sure the threads of the holder and mount are correctly aligned. Use a 1 1/4” socket

and screw the transducer assembly into the mount. Tighten to securely seat the

assembly in the mount. Do not over tighten (see Figure 3-6).

8. If replacing T-21 or T-22 transducers, install the keyed transformer assembly into the

transducer holder (see Figure 3-6).

a. Apply a small amount of Molykote 111 to the transformer assembly O-ring.

b. Insert the keyed transformer into the back end of the transducer holder.

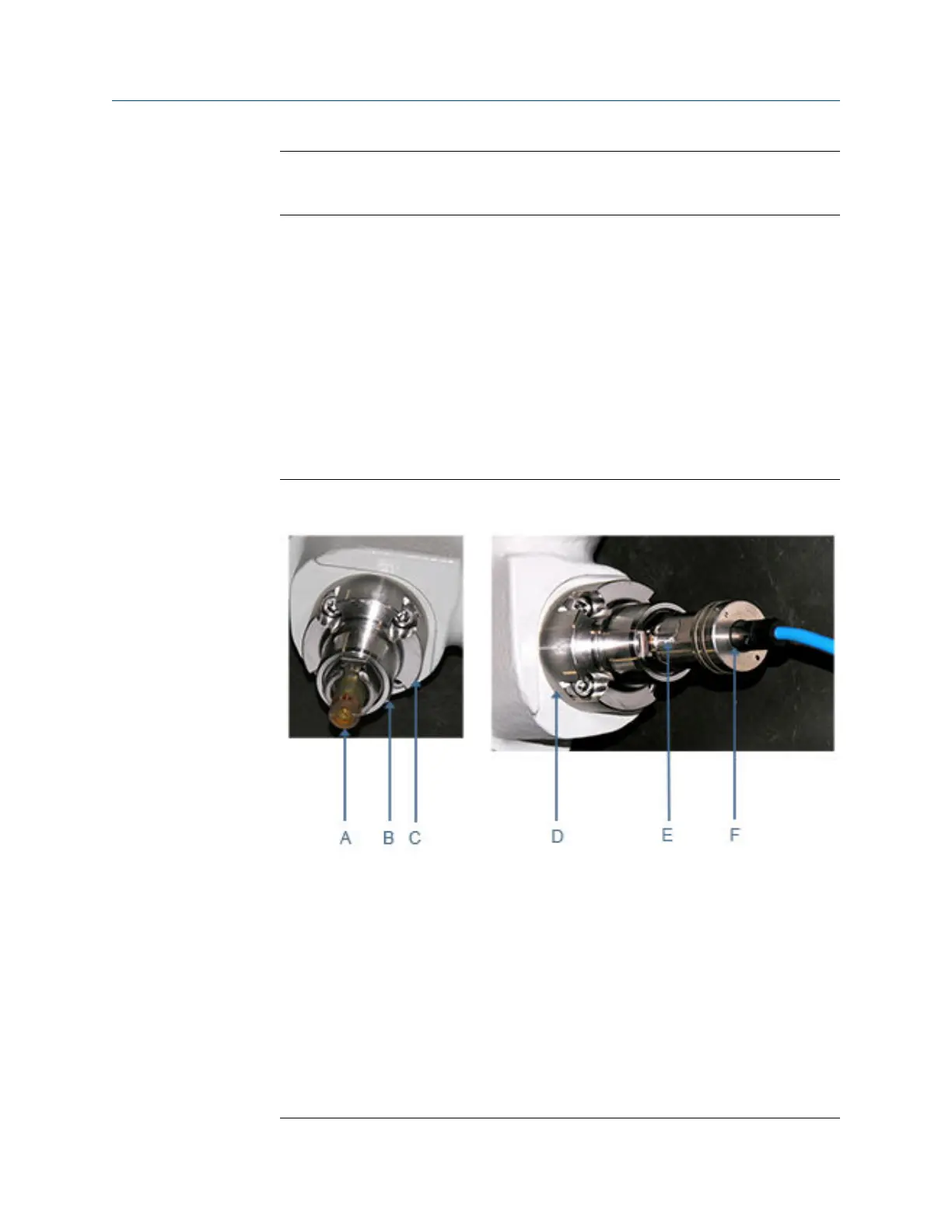

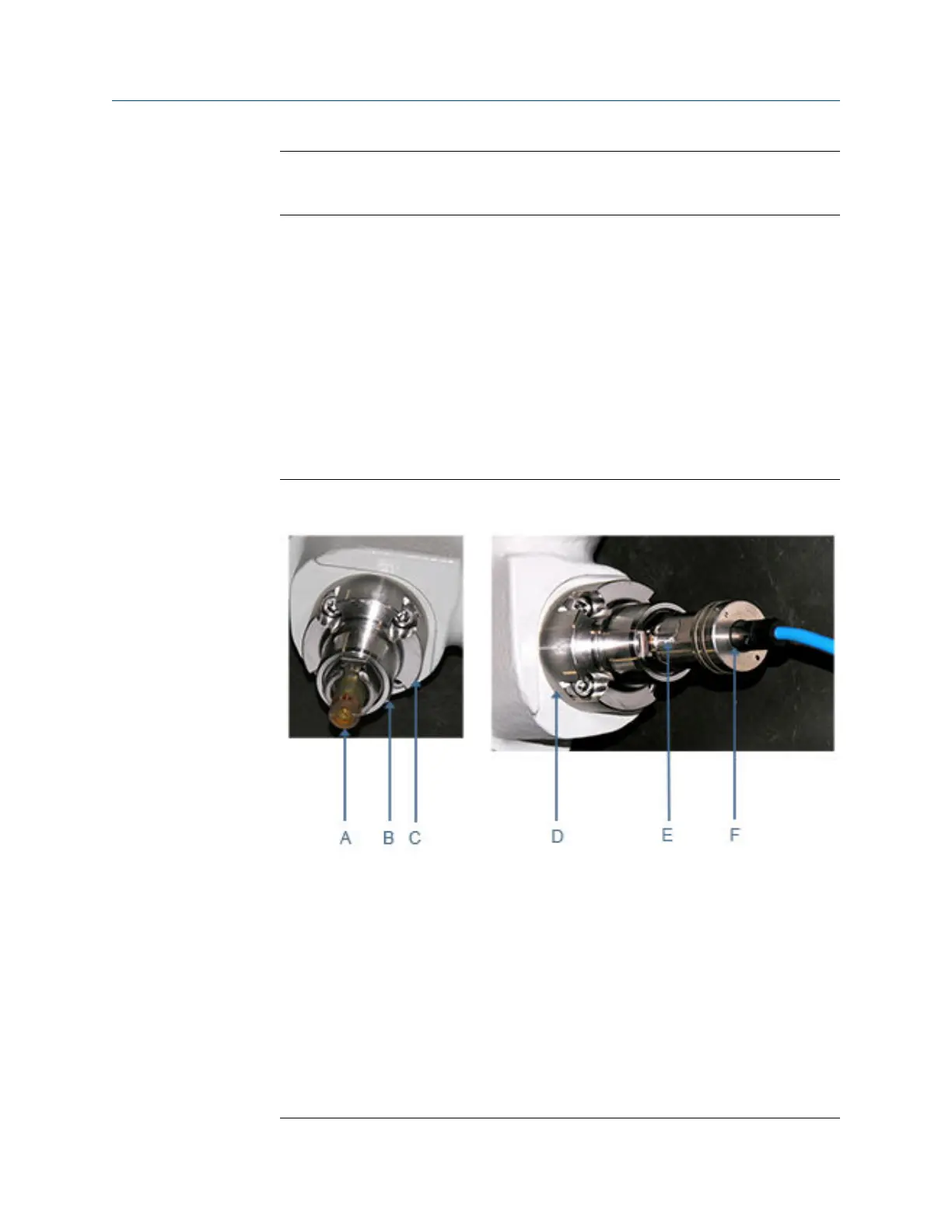

T-22 transducer assembly, holder, transformer assembly, retainer,

cable nut and chordset

Figure 3-6:

A. T-21 transformer assy. (W-01 P/N 1-360-03-090) or T-22 transformer assy. (W-02 P/N

1-360-03-110)

B. Transducer holder (Type - H1 P/N 1-360-01-128, H2 P/N 1-360-01-228)

C. Mount (Inconel mount and holder)

D. Transducer port (meter body)

E. Transducer retainer (Standard P/N 1-360-01-958) (High temperature P/N 1-360-01-978)

F. Cable nut and chordset:

• 100° C -5’ length (P/N 3-3400-190)

• 100° C -15’ length (P/N 3-3400-194)

Meter repairs

52 Gas Ultrasonic Flow Meters

Loading...

Loading...