Parameter

structure

Keypad and

format

Advanced

parameter

descriptions

Serial comms

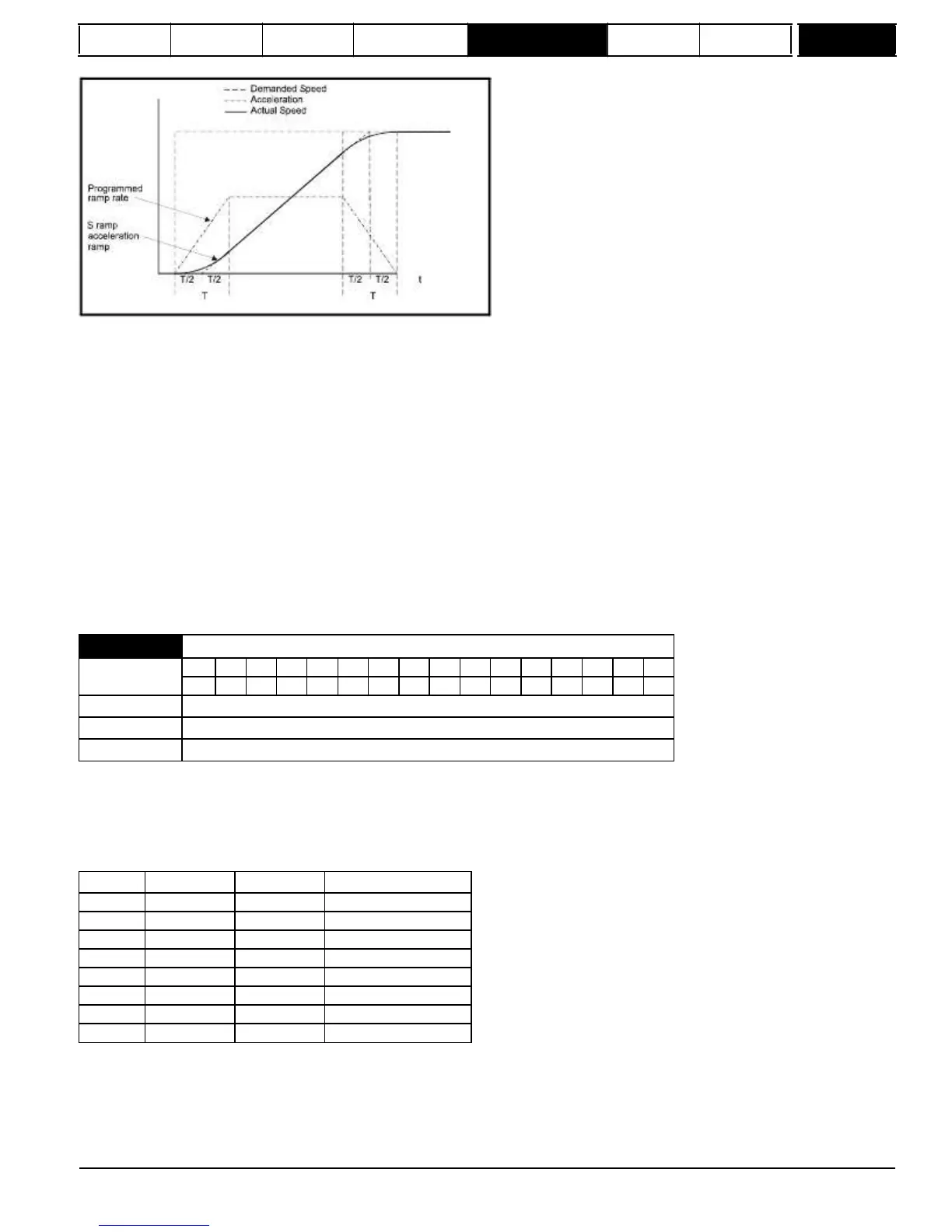

The time taken in seconds for the ramp output to change by speed (⊗w*) is given below. Two cases are given because the total ramp time must be

calculated with a different equation depending on whether the acceleration is able to reach the selected ramp rate (A1) or not. If the required change

is small the selected ramp rate is not reached and the ramp does not include the central linear ramp region. If the required change is larger the ramp

does include the central linear region as shown in the diagram above.

Speed

⊗w*

linear

=

1000

x

J

/

A1

2

where:

A = selected ramp rate

J = Pr

2.07

If

the

required

change

is

less

than

⊗w*

linear

then

T

Ramp1

should

be

used,

but

if

the

speed

change

is

greater

or

equal

to

⊗w*

linear

T

Ramp2

should

be

used.

T

Ramp1

=

2

(⊗w*

x

Pr

2.07

/

1000)

T

Ramp2

=

(⊗w*

x

A

/

1000)

+

(Pr

2.07

/

A)

The default values for the ramp rate and S ramp acceleration limit have been chosen such that for the default maximum speed, the curved parts of

the S ramp are 25 % of the original ramp if S ramp is enabled. Therefore the ramp time is increased by a factor of 1.5.

0

Ramp rate selection by terminal input

1-8

Ramp rate defined by parameter number, i.e. 1 = Pr

2.11

{

SE03,

0.24

}, 2 = Pr

2.12

, etc.

9

Ramp rate selection by Pr

1.50

When Pr

2.10

is set to 0 the acceleration ramp rate selected depends on the state of bit Pr

2.32

to Pr

2.34

. These bits are for control by digital inputs

be programmed to operate with each reference. Since the new ramp rate is selected with the new reference, the acceleration applies towards the

selected preset if the motor needs to accelerate to reach the preset.

Mentor MP Advanced User Guide

37

Issue Number: 4

www.onxcontrol.com

2.10

Loading...

Loading...