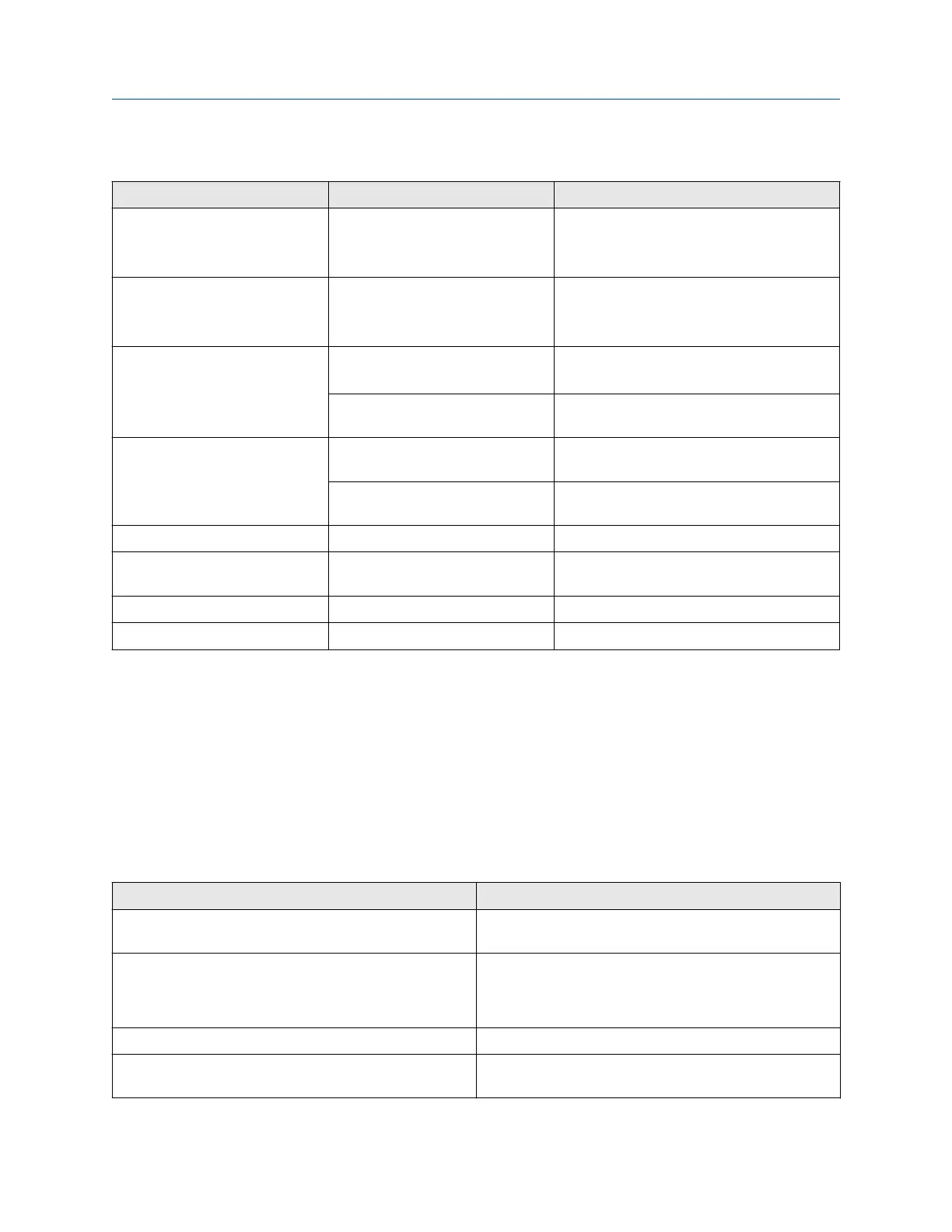

Table 15-3: Process variables problems and remedies (continued)

Symptom Cause Suggested remedy

Temperature reading

significantly different

from process temperature

RTD failure Check for alarm conditions and follow

troubleshooting procedure for indicated

alarm.

Temperature reading

slightly different

from process temperature

Sensor leaking heat Insulate the sensor.

Unusually high density

reading

Plugged flow tube Check drive gain and tube frequency.

Purge the flow tubes.

Incorrect K2 value Verify characterization. See Characterize the

meter (if required).

Unusually low density

reading

Slug flow Use standard procedures to check the quality

of the process fluid.

Incorrect K2 value Verify characterization. See Characterize the

meter (if required).

Unusually high tube frequency Sensor erosion Contact Micro Motion.

Unusually low pickoff voltages Plugged fow tube, corrosion, or

erosion

Purge the flow tubes.

Unusually low pickoff voltages Several possible causes See Check the pickoff voltage.

Unusually high drive gain Several possible causes See Check the drive gain.

15.31 Check the pickoff voltage

If the pickoff voltage readings are unusually low, you may have any of a variety of process or equipment

problems.

To know whether your pickoff voltage is unusually low, you must collect pickoff voltage data during the

problem condition and compare it to pickoff voltage data from a period of normal operation.

Drive gain and pickoff voltage are inversely proportional. As drive gain increases, pickoff voltages decrease

and vice versa.

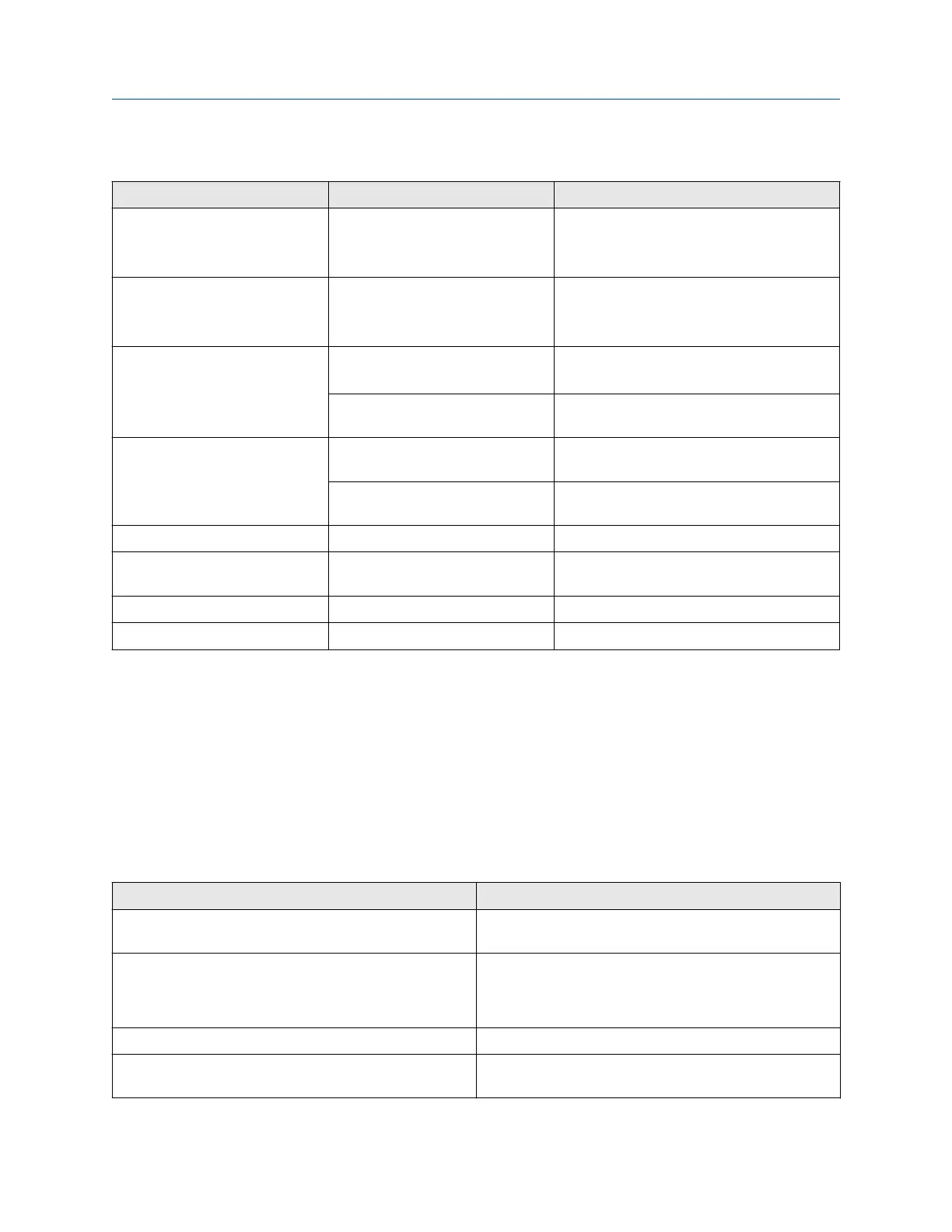

Table 15-4: Possible causes and recommended actions for low pickoff voltage

Possible cause Recommended actions

Process flow rate beyond the limits of the sensor Verify that the process flow rate is not out of range of the

sensor.

Sensor tubes are not vibrating • Check for plugging or deposition.

• Ensure that the vibrating element is free to vibrate (no

mechanical binding).

Moisture in the sensor electronics Eliminate the moisture in the sensor electronics.

The sensor is damaged, or sensor magnets may have

become demagnetized

Replace the sensor.

Configuration and Use Manual Troubleshooting

MMI-20048166 April 2019

Configuration and Use Manual 201

Loading...

Loading...