Condensing Unit Handling

Transport and Storage

Move ZX/ZXD/ZXL unit only with appropriate mechanical or

handling equipment according to weight. Keep in the upright

position. Do not stack single boxes on top of each other without

pallet in any case.

Keep the packaging dry at all times.

Application Guideline

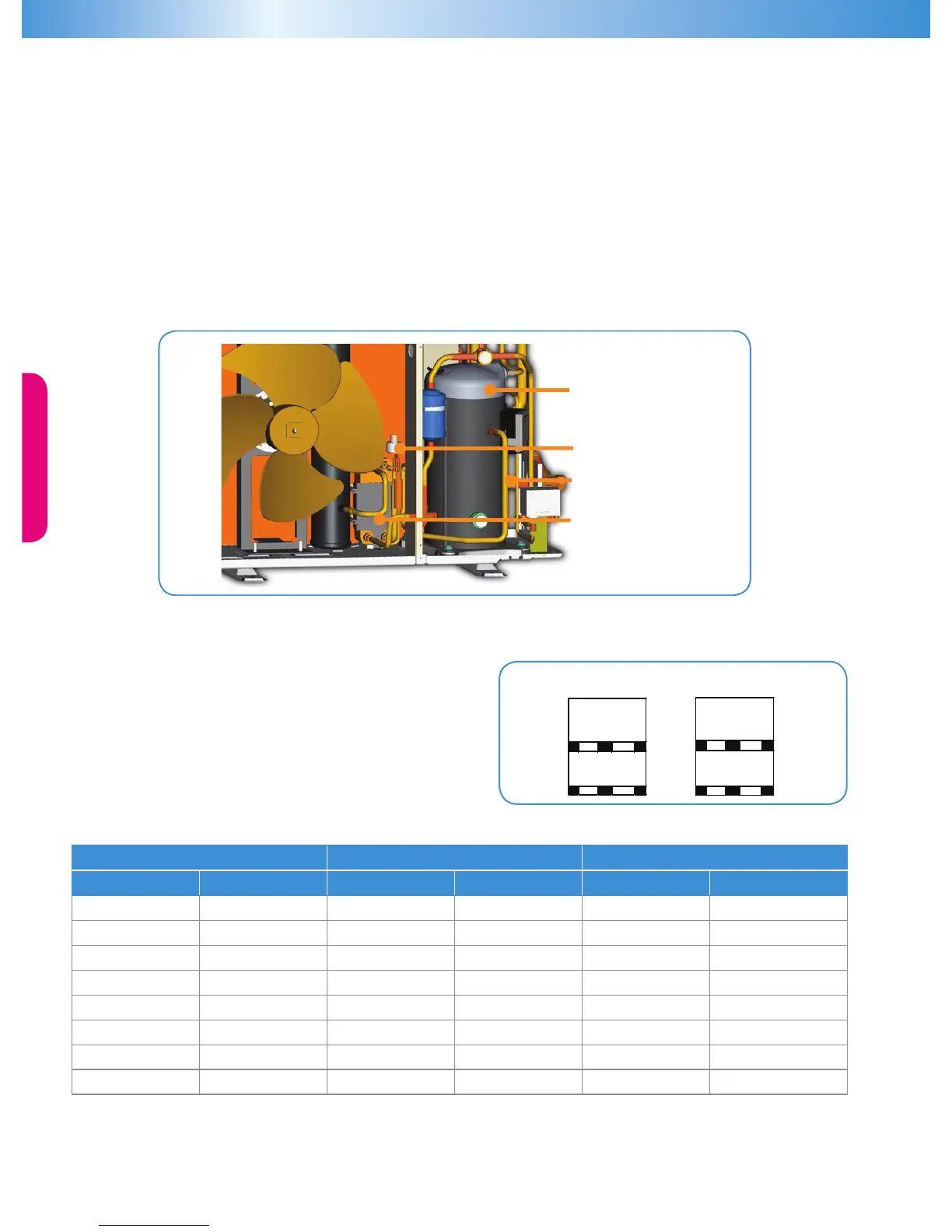

In ZX MT units, suction line injection is applied to the compressor suction. Suction line injection allows a reliable and efcient MT

envelope of up to -15°C (R22) and -20°C (R404A) evaporating temperature. In suction line injection, a part of liquid refrigerant is

added into the compressor suction gas. Suction injection de-superheats the suction gas and controls the compressor discharge

temperature. This is implemented through electronic control by the E2 controller and an electronic expansion valve (EXV). The E2

monitors the compressor discharge temperature and optimizes the opening of the EXV for optimal discharge gas control.

In ZXL LT units, vapor injection is applied to the compressor. Vapor injection enhances the compressor efciency by applying 2-stage

compression with an economizer refrigeration cycle. Vapor injection eliminates the need for liquid injection, which would otherwise

have been required to operate a reliable LT envelope down to -40°C evaporating temperature. In vapor injection, a part of liquid

refrigerant is expanded and passed through a heat exchanger. In the heat exchanger, this expanded refrigerant absorbs heat from the

main liquid line and sub-cool the main liquid. The expanded refrigerant vaporizes while passing through the heat exchanger and is

supplied back into the scroll intermediate pockets through the vapor-injection tube. The sub-cooling of the main liquid increases the

compressor capacity by as much as 30%. The gure 14 below identies the key components of the vapor injection assembly.

Figure 07: Key Components Of The Vapor Injection Assembly

Net Weight

ZX ZXD ZXL

Model Weight (kg) Model Weight (kg) Model Weight (kg)

ZX0200/E 76 ZXD0400/E

2

104 ZXL0200/E 79

ZX0250/E 79 ZXD0500/E

3

112 ZXL0250/E 81

ZX0300/E 79 ZXD0600/E

4

114 ZXL0300/E 81

ZX0400/E

1

91 ZXD0750/E

5

122 ZXL0350/E 93

ZX0500/E 108 ZXL0400/E 93

ZX0600/E 112 ZXL0500/E 106

ZX0750/E 118 ZXL0600/E 116

ZX0760/E 121 ZXL0750/E 121

Notes:

1

100 kg for models under 60 Hz TF5/7 and 50 Hz PFJ

2

109 kg for models under 60 Hz TF7

3

117 kg for models under 60 Hz TF7

4

121 kg for models under 60 Hz TF7

5

127 kg for models under 60 Hz TF7

Loading...

Loading...