System integration Deltabar PMD75B PROFINET with Ethernet-APL

44 Endress+Hauser

Status Coding (hex) Meaning

GOOD - Maintenance demanded 0xA8 The measured value is valid.

It is highly advisable to service the device in the near future.

GOOD - Function check 0xBC The measured value is valid.

The device performs an internal function check. The function check does

not have any noticeable effect on the process.

8.3.4 Startup configuration

Startup configuration

(NSU)

The automation system adopts the configuration of the most important parameters of the device.

• Management:

• Display operation

• Web server functionality

• Bluetooth activation

• Service CDI

• System units:

• Pressure unit

• Temperature unit

• Scaled variable unit

• Process:

Damping

• Alarm delay

• Diagnostic settings

• Diagnostic behavior for diverse diagnostic information

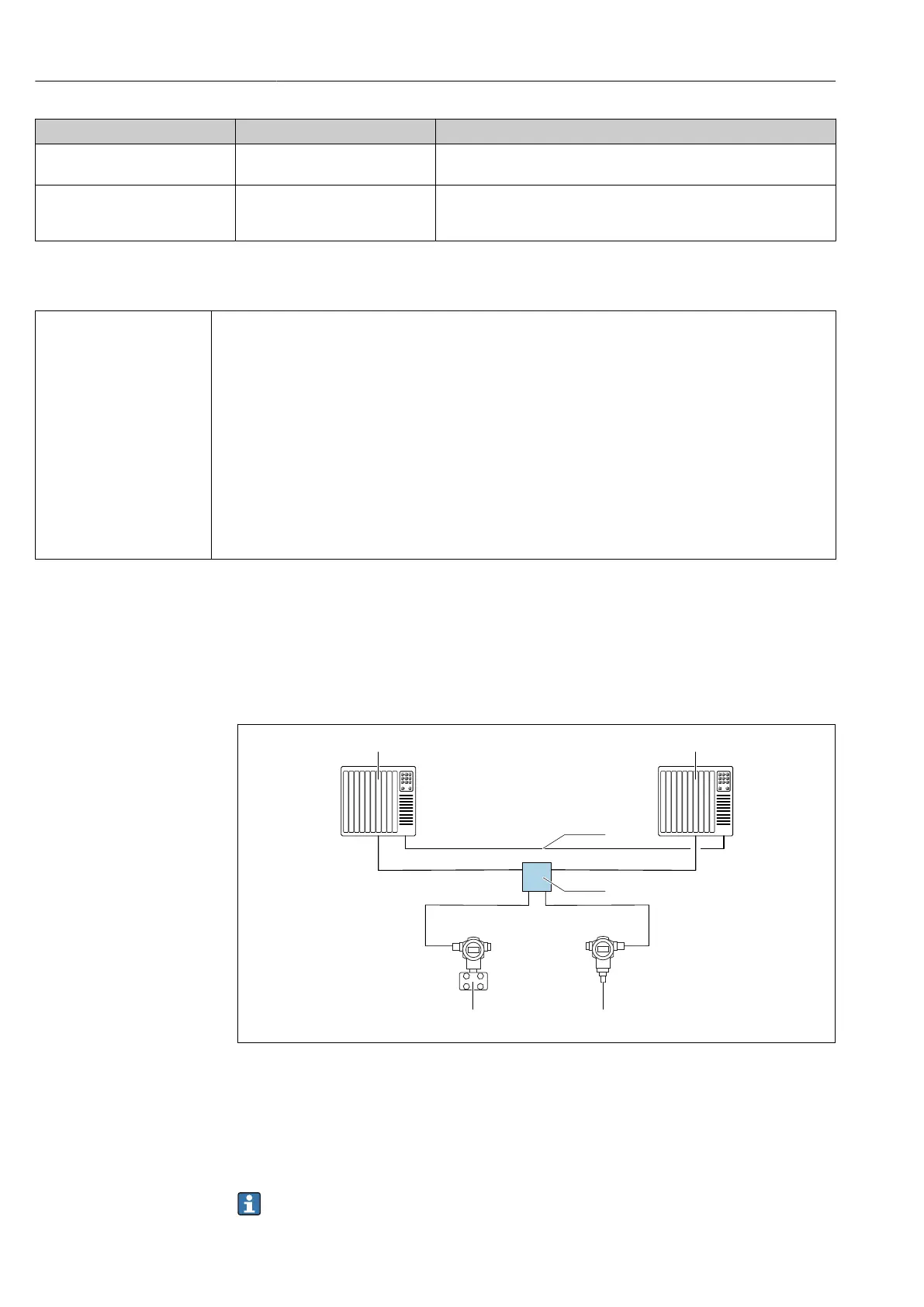

8.4 System redundancy S2

A redundant layout with two automation systems is necessary for processes that are in

continuous operation. If one system fails the second system guarantees continued,

uninterrupted operation. The device supports S2 system redundancy and can communicate

simultaneously with both automation systems.

A0046154

8 Example of the layout of a redundant system (S2): star topology

1 Automation system 1

2 Synchronization of automation systems

3 Automation system 2

4 Ethernet-APL Field Switch

5 Device

All the devices in the network must support S2 system redundancy.

Loading...

Loading...