Mounting Deltabar PMD78B PROFINET with Ethernet-APL

18 Endress+Hauser

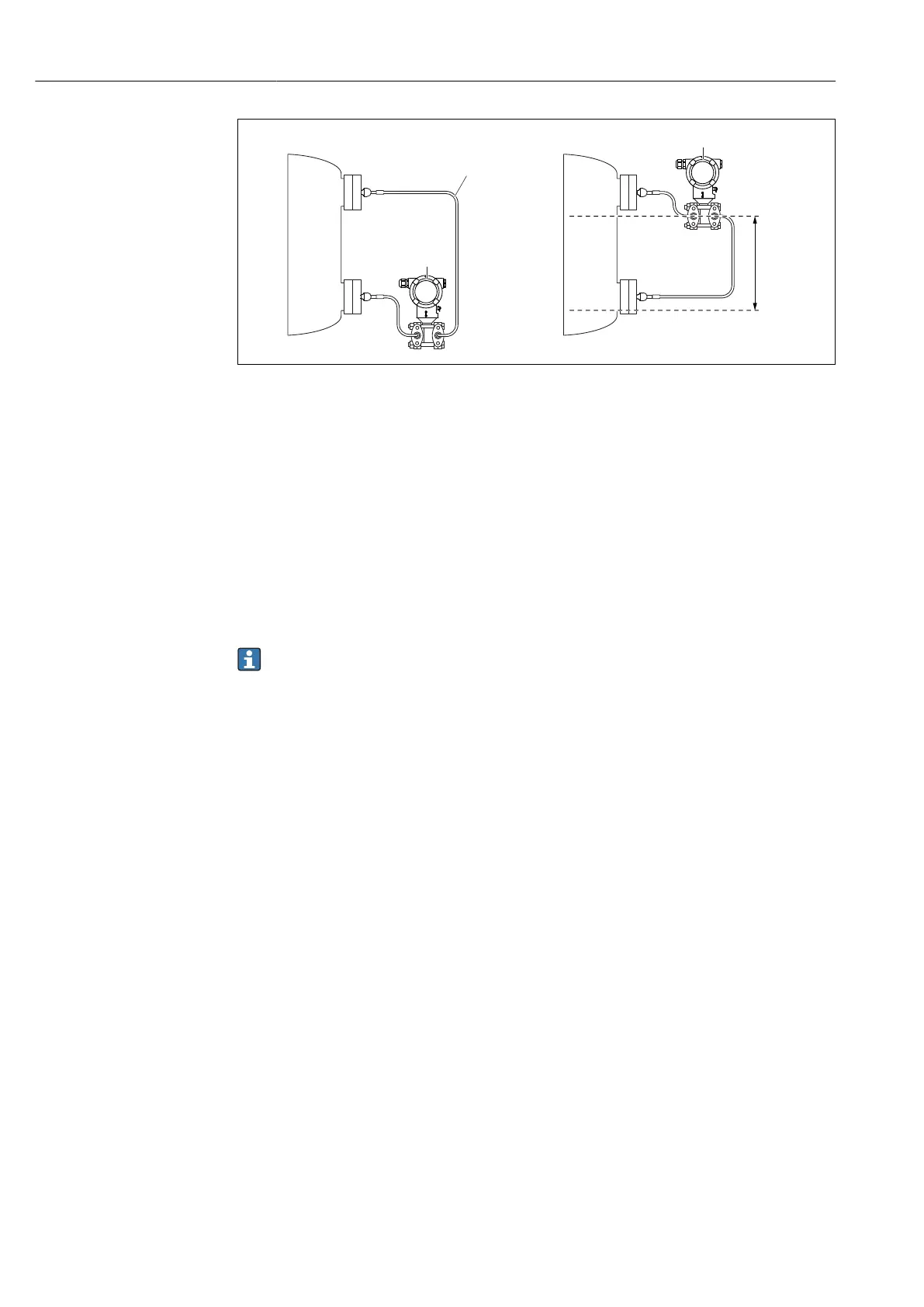

1

+ -

h1

– –

+ +

+ -

A B

2

≥ 100 (3.94)

1

A0038720

Unit of measurement mm (in)

A Recommended installation in a vacuum application

B Installation above the lower diaphragm seal

h1 Height difference (is shown in the Applicator "Sizing Diaphragm Seal")

1 Device

2 Bending radius ≥ 100 mm (3.94 in). Ensure strain relief to prevent the capillary from bending.

The maximum height difference depends on the density of the fill fluid and the lowest

absolute pressure that can ever occur at the diaphragm seal (empty vessel).

Information on cleaning

Endress+Hauser provides flushing rings as an accessory to enable the membrane to be

cleaned without removing the transmitter from the process.

For more information: contact the Endress+Hauser sales office.

5.1.4 Installing pressure piping

• For recommendations for routing pressure piping, refer to DIN 19210 "Differential

pressure piping for flow measurement devices" or the corresponding national or

international standards

• When routing the pressure piping outdoors, ensure sufficient anti-freeze protection, e.g.

by using pipe heat tracing

• Install the pressure piping with a monotonic gradient of at least 10%

Loading...

Loading...