General Safety Information

Safety Manual 2

–5

Potential Risks Affecting Personnel

This section addresses the appropriate actions to undertake before or during

service of the analyzer when faced with hazardous situations such as exposure

to process gases, electrocution, explosion or fire. It is not possible to list all

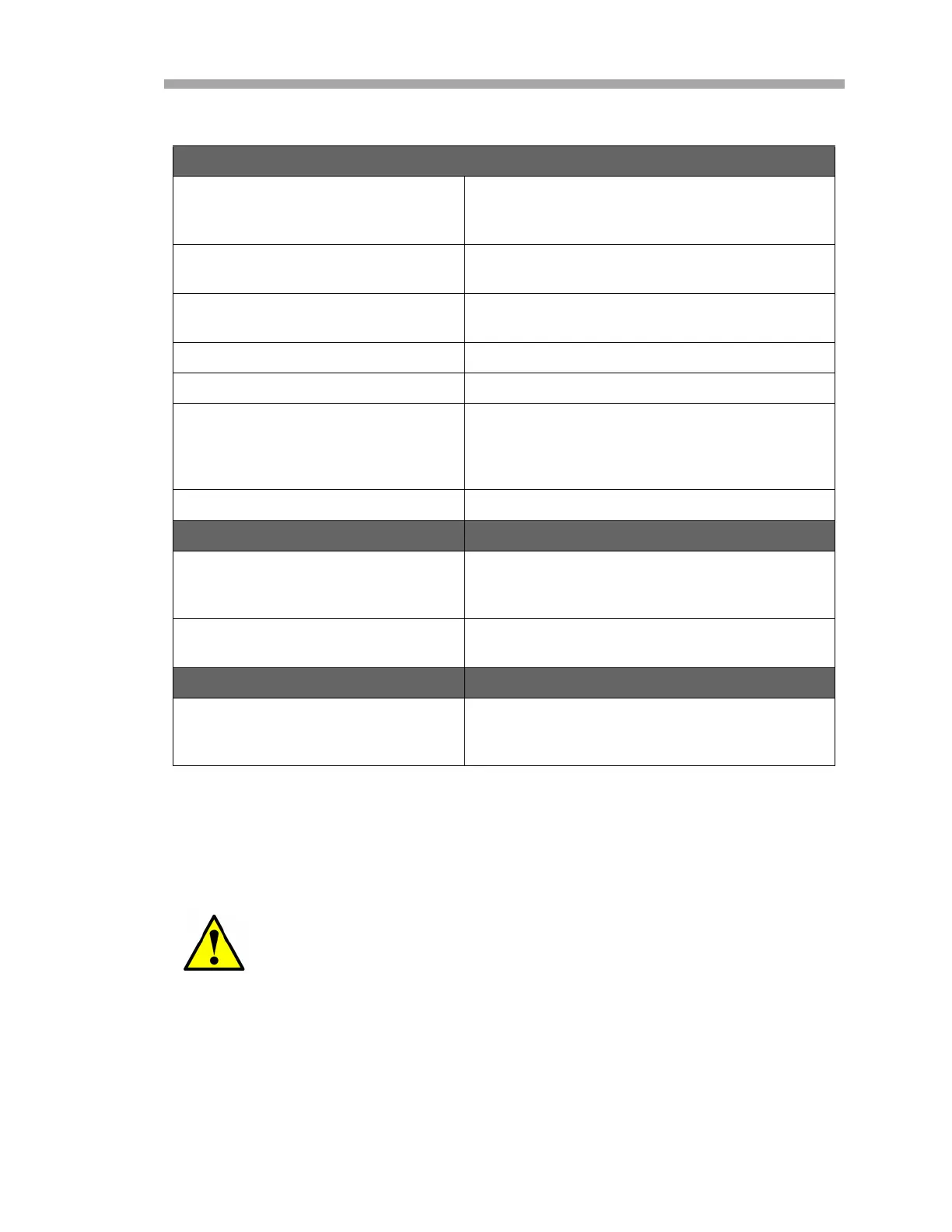

Table 2-1 SS2100 analyzer equipment ratings and specifications (Continued)

Application Data

Environmental Temperature

Range/Sample Cell Temperature

Range

–20 C to 50 C (–4 F to 122 F)

–10 C to 60 C (14 F to 140 F) - Optional

Environmental Relative

Humidity

5% to 95%, Non-condensing

Heated SCS Enclosure

Temperatu r e

50 C (122 F)

60C (140 F) - Optional

Altitude Up to 2,000 m

Sample Inlet Pressure 130-340 kPaG (20-50 PSIG) to panel

Sample Cell Operating Pressure

Range

800-1200 mbara (80-120 kPa)(11.5-17.4

PSIA)

950-1700 mbara (95-170 kPa)(13.8-24.6

PSIA) - Optional

Sample Flow Rate

2

0.5-4 LPM (0.02-0.1 SCFM)

Physical Specifications

Size (typical)

2

1300-1500 mm H 600-920 mm W 300-

450 mm D (50-60” H 24-36” W 12-

17” D)

Weight (typical)

2

Approximately 59 Kg (130 lbs) with Sample

System

Area Classification

Analyzer with Sample Conditioning

System (SCS)

Class I, Div.2 Grp. A, B, C, D T3 / T3C

Class I, Zone 2 IIC T3 / T3C

Type 4X, IP66

2. Application dependent.

Technicians are expected to follow all safety protocols established

by the customer that are necessary for servicing the analyzer.

This may include, but is not limited to, lockout/tagout procedures,

toxic gas monitoring protocols, PPE requirements, hot work

permits and other precautions that address safety concerns

related to performing service on process equipment located in

hazardous areas.

Loading...

Loading...