Maintenance and Service

Safety Manual 5

–7

9. Place the filter unit into the analyzer and tighten the base with the

four screws.

10. Check upstream of membrane for liquid contamination and clean

and dry out before opening the sample supply valve.

11. Check connections for gas leaks. SpectraSensors recommends using

a liquid leak detector.

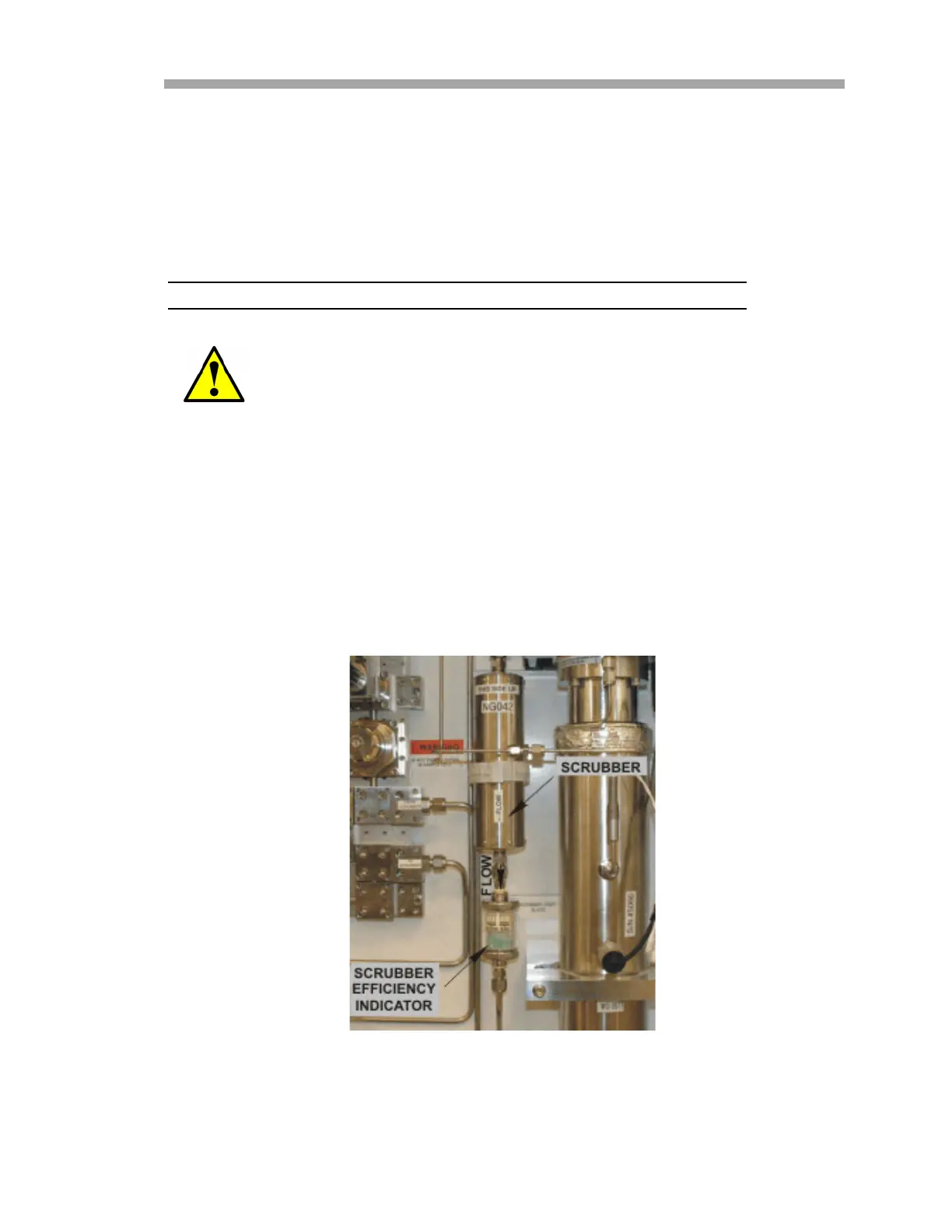

Replacingthescrubberandscrubberefficiencyindicator

1. Close the sample supply shut-off valve. Allow all residual gas to

dissipate as indicated by no flow on the sample bypass flow meter.

2. Unscrew the compression nuts on the inlet end of the scrubber and

scrubber efficiency indicator assembly.

3. To install the new scrubber and indicator, insert the inlet and outlet

tubes into the compression fittings of a new scrubber and scrubber

efficiency indicator assembly, ensuring each are oriented correctly,

as shown in Figure 5–5 below.

All valves, regulators, switches, etc. should be operated in

accordance with site lock-out/tag-out procedures.

Figure 5–5 Scrubber and scrubber efficiency

indicator

Loading...

Loading...