26

REV. 09/2020

27

REV. 09/2020

TROUBLESHOOTING TROUBLESHOOTING

3 3

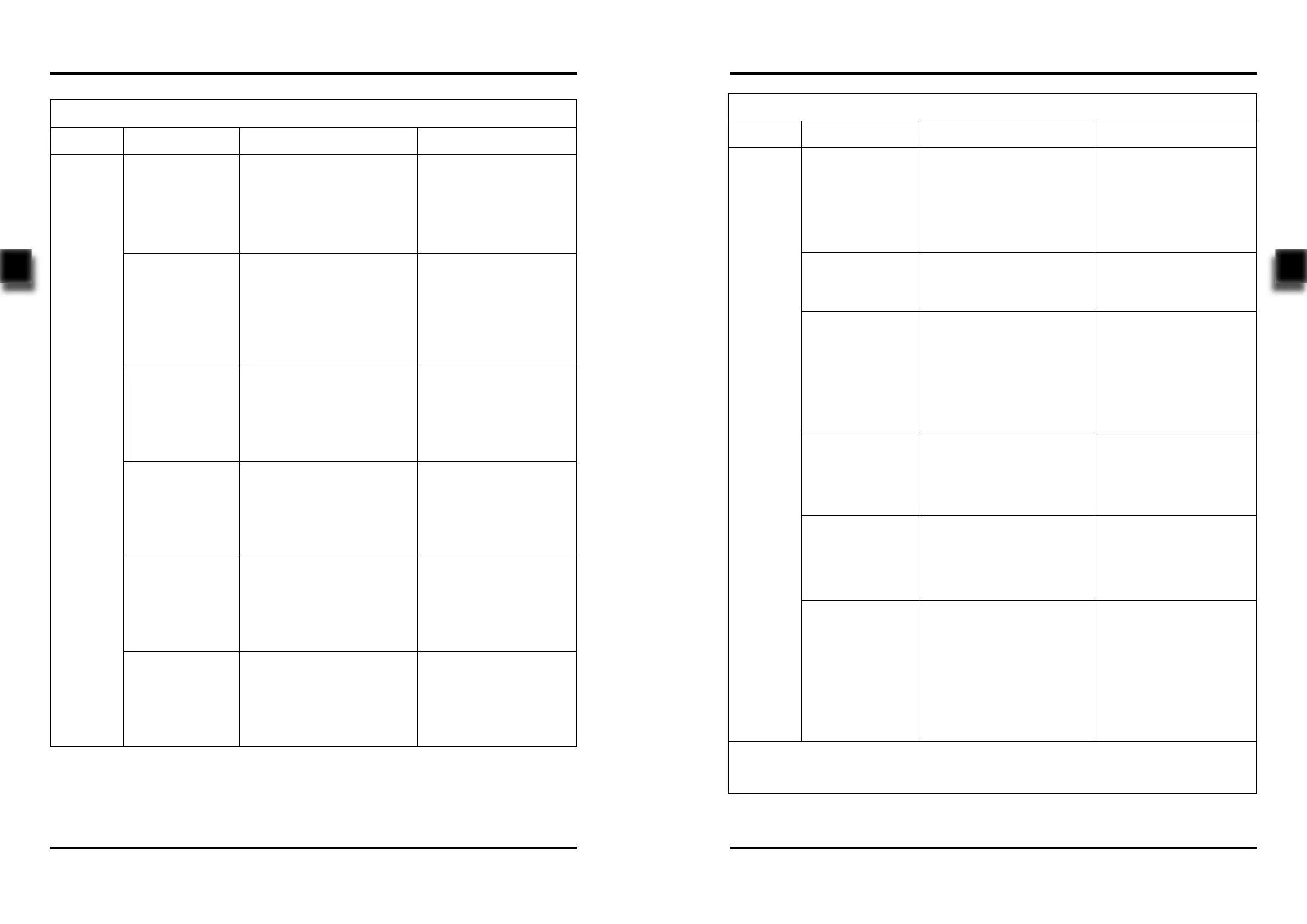

Table 3.1 Troubleshooting of Common Faults (continued)

Fault Fault Symptom Probable Causes Troubleshooting

Lifting System

Failure

1. Slow Lifting of

Vehicle

• Overload

• Hydraulic pipeline leakage

• Valve failure:

• Gear pump wear, internal

leakage occurs

• Insucient relief valve pressure

or blocked

1. Refer to the rated capacity

marked on the nameplate;

2. Check the pipe and hydraulic

components for oil leaks;

3. Wash or replace the valve

body

2. Slow Lowering of

Vehicle

• Solenoid valve blocking

• Valve body failure: throttle valve

failure or blocked

1. Wash or replace the solenoid

pool

2. Wash or replace the valve

body

3. Unstable Lifting /

Lowering of Vehicle

• Chain loosening;

• Poor lubrication between steel

channel and rollers;

• Improper adjustment of rollers, or

blocked.

1. Adjust the chain tension;

2. Check if the steel channel

grease is normal, clean and

relubricate steel channel and

rollers;

3. Adjust the side roller spacing

through roller screw; or

replace the roller.

4. Fork arm carrier or

mast tilt by itself.

• Tilt cylinder and ring abraded

excessively

• The hydraulic control valve spring

is inoperative.

1. Replace piston ring tilt

cylinder.

2. Replace it.

5. The fork arms carrier

moves up and down

sluggishly.

• Caused by piston jamming or

bent piston rod.

• Too much dirt is accumulated in

the cylinder.

1. Replace the faulty parts.

2. Strip it down and clean.

6. Forks are lifted or

lowered unsmooth.

• Carriage bracket assembly out of

adjustment.

• Insucient clearance between

inner and outer masts or rollers

and mast.

• Biting foreign materials between

moving parts.

• Insucient lubrication.

• Bent carriage bracket assembly.

1. Adjust clearance with thrust

metal and carriage side roller.

2. Adjust clearance with rollers.

3. Remove foreign materials.

4. Apply grease on contact sur-

faces of sliding parts.

5. Repair or replace.

* Under the circumstances of normal lifting and lowering, if failure occurs to any of other

hydraulic actions (forward/backward shifting, forward/backward tilting and left/right shifting),

perform troubleshooting to the corresponding control switch and its control circuit.

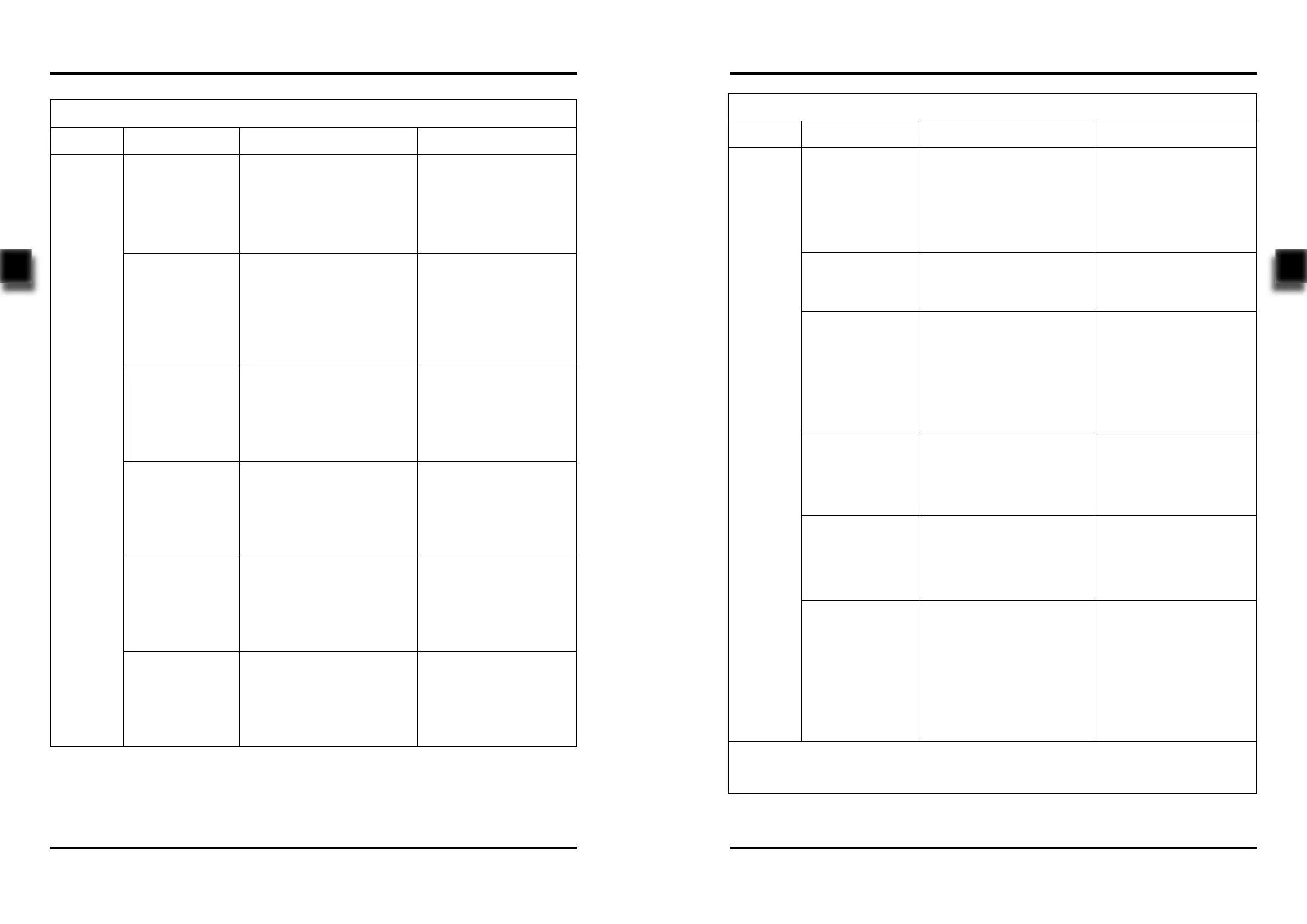

Table 3.1 Troubleshooting of Common Faults

Fault Fault Symptom Probable Causes Troubleshooting

Hydraulic

Failure

1. Noisy pump

• Insucient oil;

• High viscosity of oil;

• Oil suction pipe air leak;

• Filters clogged by impurities;

• Hydraulic oil with foam;

1. Check the hydraulic oil level.

2. Replace the hydraulic oil.

3. Check the oil suction pipe.

4. Clean the oil inlet piping, re-

place the lter, if necessary.

5. See Fault 2.

2. Hydraulic oil with

foam

• Pump cavitation;

• There is water in the oil.

1. Check the amount of oil;

2. Check if the viscosity of hy-

draulic oil is normal;

3. Check the oil inlet piping for

air leaks;

4. Discharge and clean, and

replace with new hydraulic

oil.

3. Pump or oil

temperature is too

high

• Oil is too thin;

• Pump cavitation;

• Valve body internal relief.

1. Discharge and clean, and

add new hydraulic oil;

2. Check the oil inlet piping for

air leaks;

3. Replace the valve body.

4. Low System

Pressure

• Insucient oil;

• Relief valve failur

• Pump wear, internal leakag

1. Check the hydraulic oil level;

2. See Fault 6;

3. Replace the gear pump.

5. On load, declined • Solenoid valve failure;

1. Check and clean the solenoid

valve spool.

2. Check the multi-way manual

valve and it installation.

6. Relief valve pressure

unstable or too low

• Pressure adjustment screw too

loose;

• Relief valve spring breakage or

deformation;

• Relief valve spool wear or

blocked.

1. Adjust to proper pressure

through hydraulic pressure

gauge.

2. Replace the relief valve.

3. Clean or replace the relief

valve.

* Carry out trouble shooting in accordance with the order listed in the table, it can help you quickly

identify problems and resolve accordingly.

Loading...

Loading...