51

6

50

REV. 09/2020

STEERING SYSTEM

5

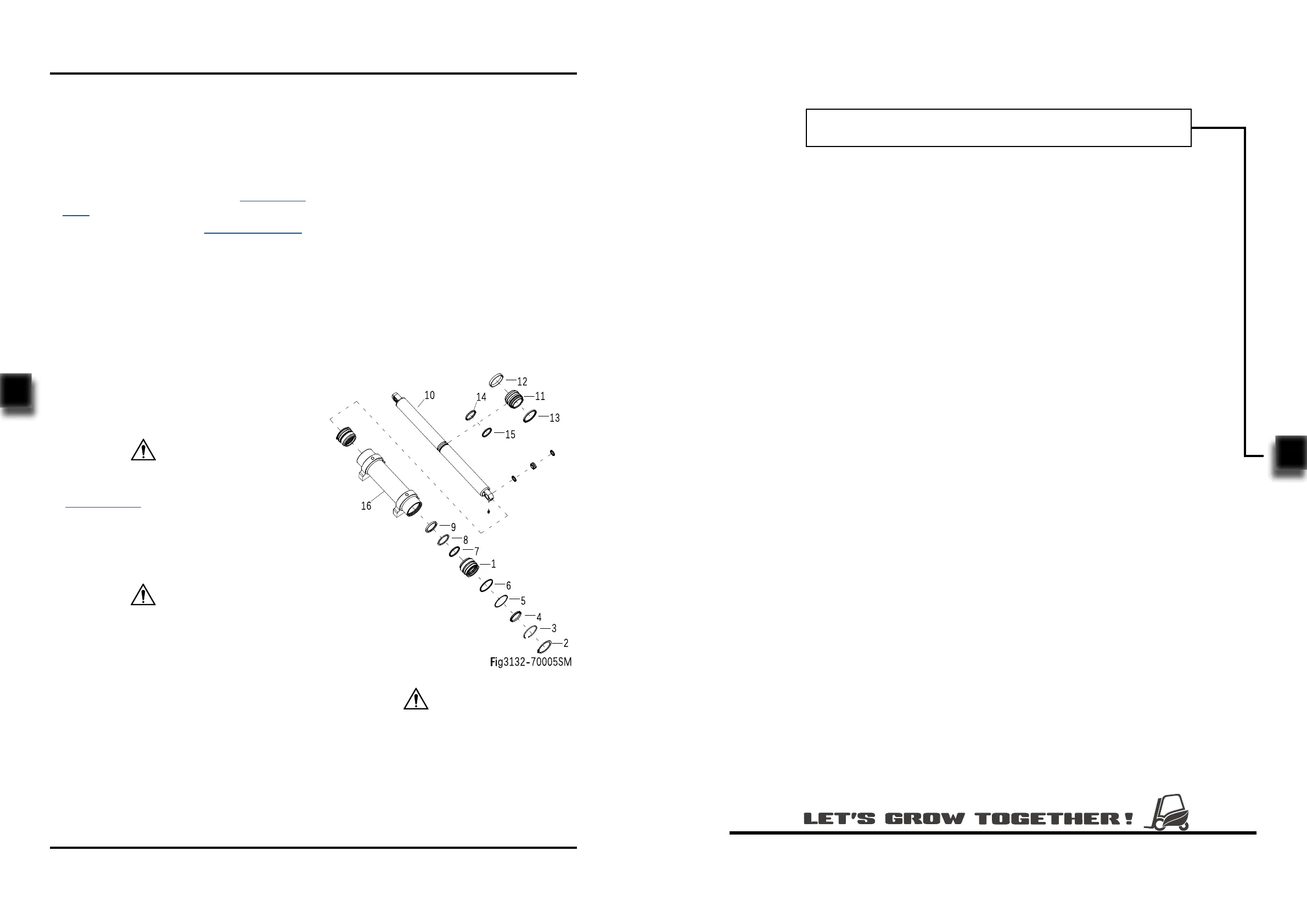

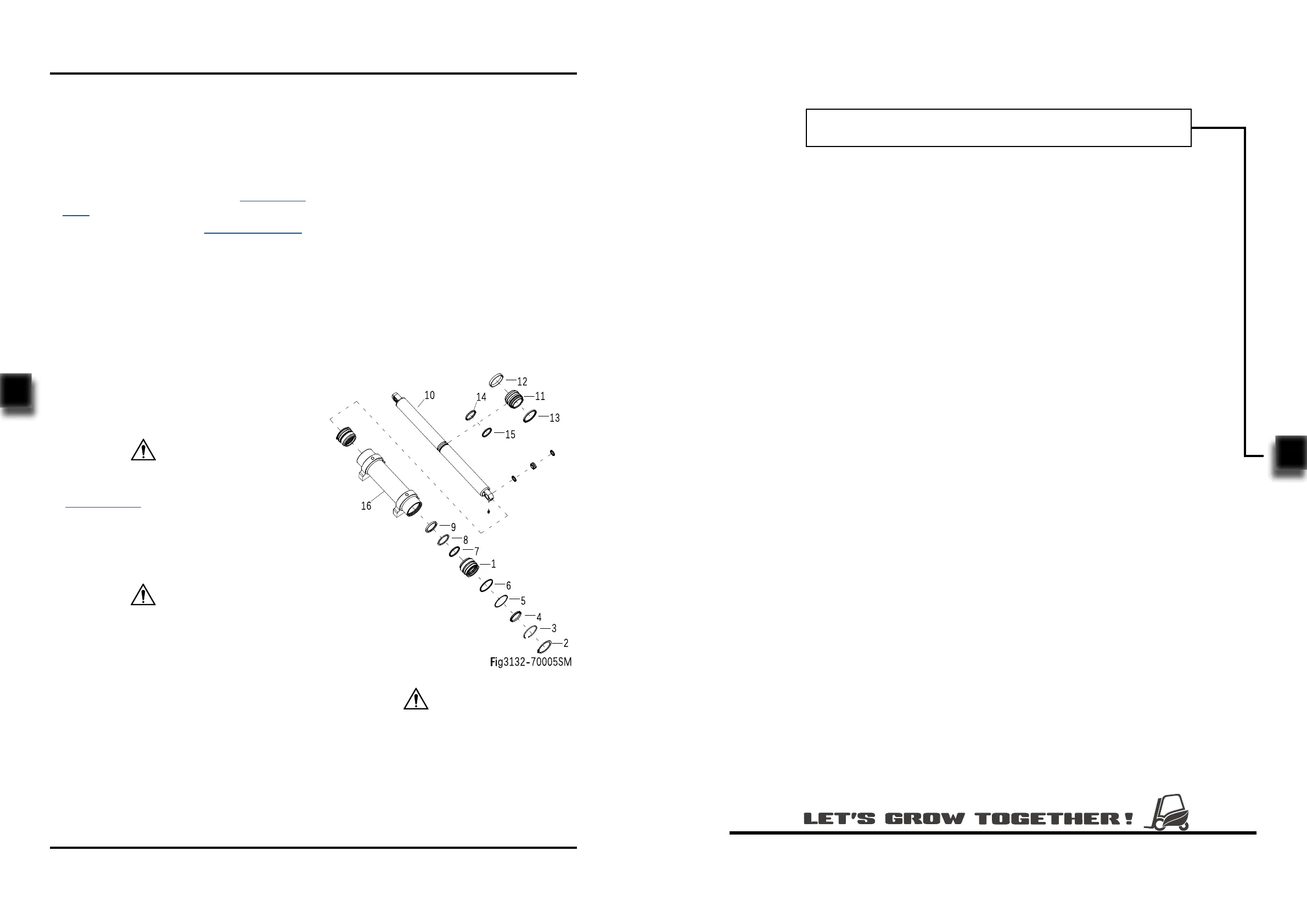

5.3 Steering Cylinder

5.3.1 Removal and Installation

Removal

Installation

- Install according to the reverse order of rem-

oval.

- Turn o the truck power and remove the key;

- Dismantle the steering bridge; (see Section

5.2.1)

- Unscrew the four bolts (24,Fig3132-70004SM)

and remove the space plate (23) from the

connect rod (20);

- Knock out the pin (11), then remove the two

check rings (12) and bearing (13);

- Unscrew the four bolts (14) and dismantle the

steering cylinder (21) from the steering bridge

(22).

When removing the steering cylinder, the

system will lose some hydraulic oil, please refer

to Section 2.2.3 for supplementary adding of

hydraulic oil.

CAUTION

5.3.2 Steering Cylinder Maintenance

-

-

-

Use suitable hose clamps to avoid cylinder

deformation caused by severely tight hose

clamp.

Carry out the maintenance work in a clean

environment to prevent impurities from enter-

ing into cylinder, causing cylinder damage;

During the installation, hydraulic oil of

the same specifications must be used for

cleaning or lubrication.

- Secure the cylinder to hose clamp and gently

clamp the cylinder middle;

- Unscrew the cylinder cap (1,Fig3132-

70005SM) from side with cylinder wrench;

- Remove the circlip (2), snap ring (3), dust ring

(4), rubber ring (5&8), O-ring (6 & 7) and seal

(9) from the cylinder cap;

- Pull out the piston rod (10) from cylinder block

(16);

- Separate the piston (11) from the piston rod;

- Remove the support ring (12), O-ring (13),

seal (15) and balls (14) from the piston;

-

-

Clean with hydraulic oil of the same specifi-

cations;

Replace the problem parts and assembly in

reverse steps.

-

-

-

If the piston rode or cylinder tube is damaged,

please replace the entire cylinder.

If the seals are aged or damaged, please

replace the complete set of seals.

When replacing or repairing the cylinder,

please rell the lubricant through the grease

nipples at both ends of the cylinder.

CAUTION

CAUTION

6. BRAKE SYSTEM

Loading...

Loading...