Epec CAN Module Family

2024 CONTROL MODULE

12 / 34

07.10.2010

2024G08,G18 / MAN000185

Epec Oy reserves all rights for improvements without prior notice

Epec Oy Postiosoite/Postal address Puhelin/Phone Fax Internet

Tiedekatu 6 PL/P.O.Box 194 +358-(0)20-7608 111 +358-(0)20-7608 110 www.epec.fi

FIN-60320 Seinäjoki FIN-60101 Seinäjoki, Finland

3.4 Digital Input / PWM Output / Digital Output

These pins are current sourcing outputs. In other words, pin connects the load to positive supply

voltage. The application program can also simultaneously monitor the actual state of the pin.

This feature makes it possible to detect short circuits to the ground. Open loads can not be

detected because the internal load resistor is connected to the ground.

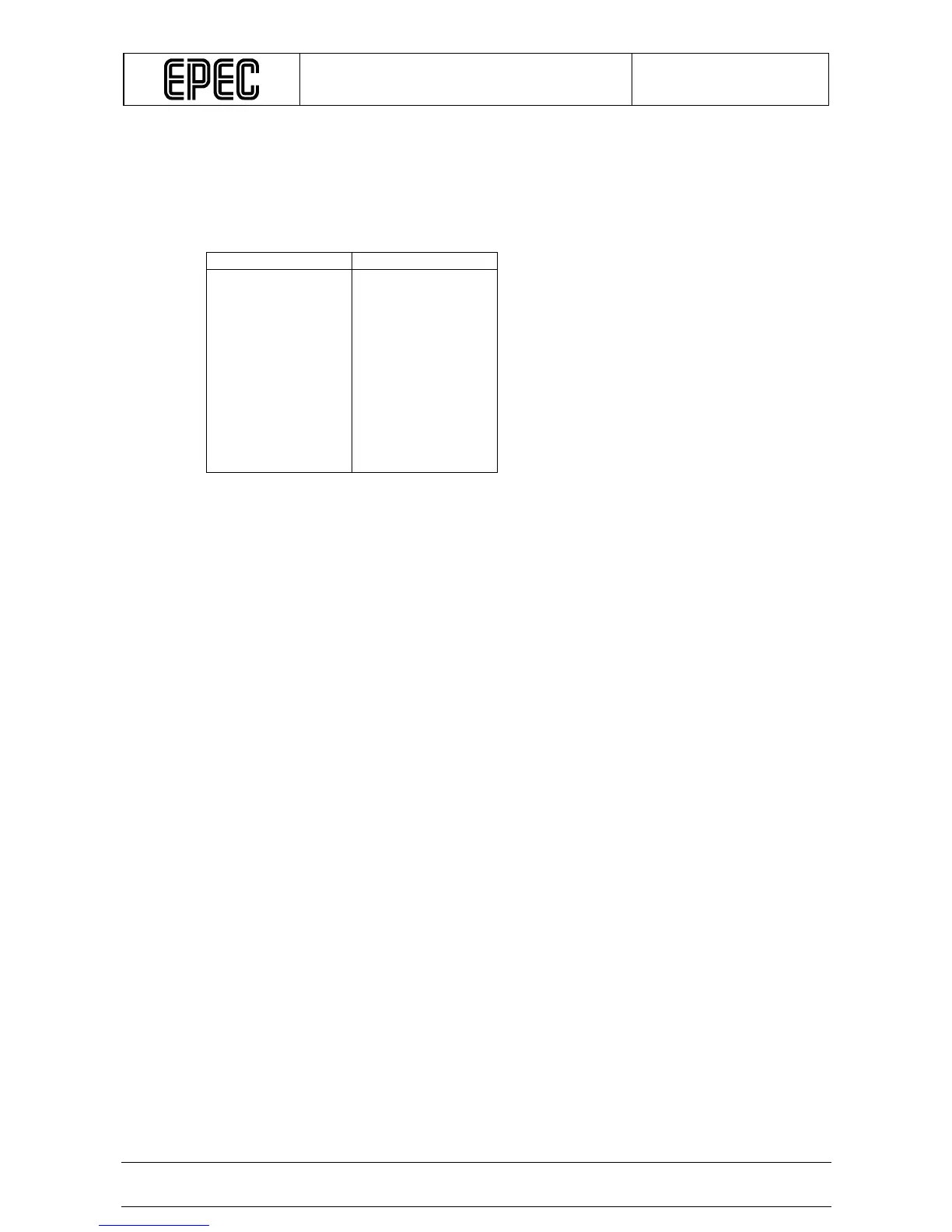

Connector X1 Connector X2

X1.1

X1.2

X1.3

X1.4

X1.7

X1.8

X1.14

X1.15

X1.16

X1.17

X1.22

X1.23

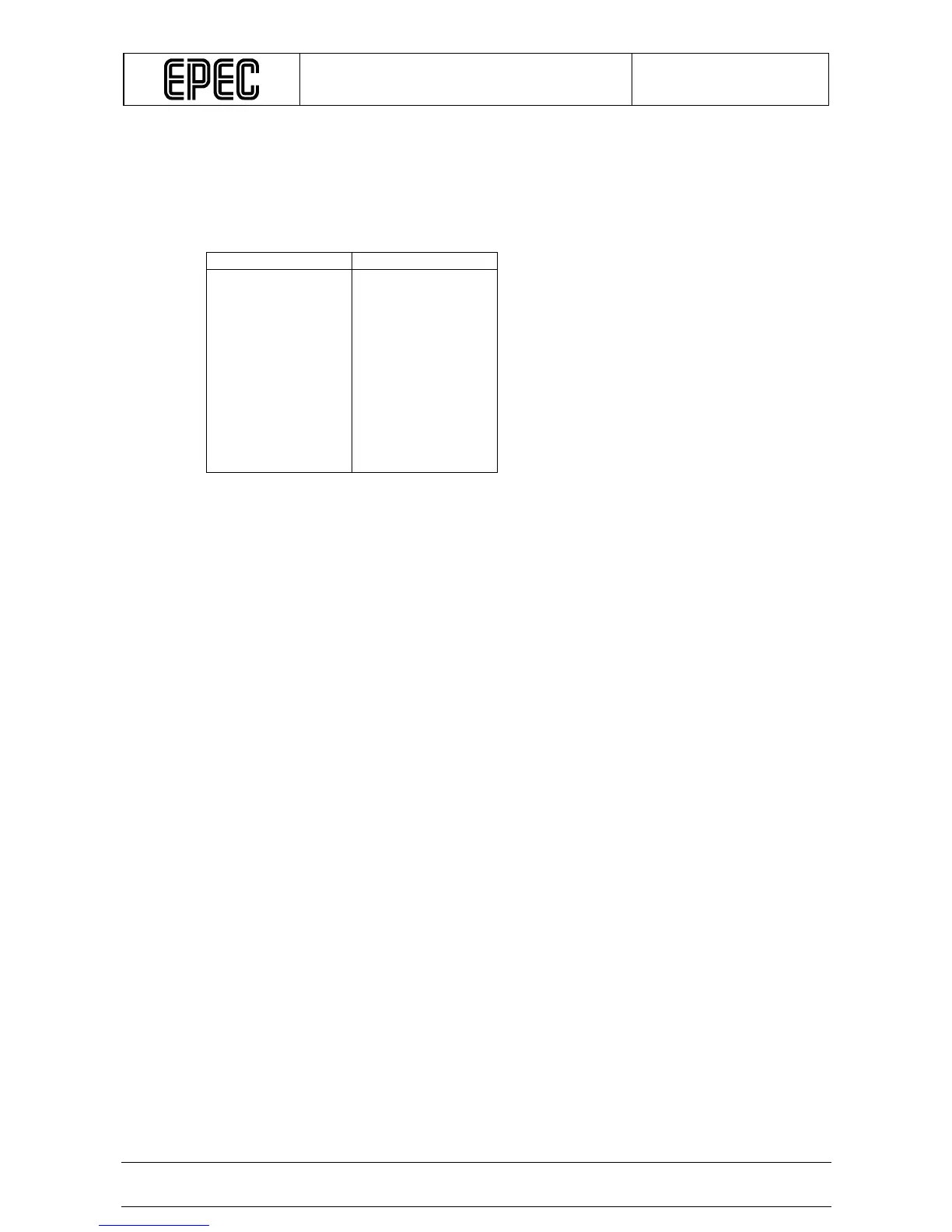

X2.1

X2.2

X2.5

X2.6

X2.7

X2.8

X2.9

X2.10

X2.16

X2.17

X2.22

X2.23

These kind of outputs are also capable to generate pulse width modulated (PWM) output

signals. This feature is useful when driving proportionally controlled loads, e.g. proportional

hydraulic valves. Monitoring the state of the pin is generally not possible when the pin is used as

a PWM signal output.

PWM frequencies can be configured under software control in groups of outputs. The frequency

is set by HW_SET_PWM_FREQ function call. The setting is done by a PWM channel but

setting the frequency of one channel sets also the frequencies of all the other channels in the

same groups.

In very carefully selected applications a pin of this type can also be used as an input by using

the output state monitoring feature. In those cases, the output functionality of the pin must of

course be kept in off state. It must be taken care in system design that the output unintentionally

switching to on state causes no harm to the system.

Loading...

Loading...