Maintenance 14. Calibration

G3 Rev.14 183

-4 Execute the absolute encoder initialization command.

Input one of the following commands

to [Command Window] according to the

joint being calibrated.

Joint #1:

>EncReset 1

Joint #2:

>EncReset 2

Joint #3:

>EncReset 3

Joint #4:

>EncReset 3, 4

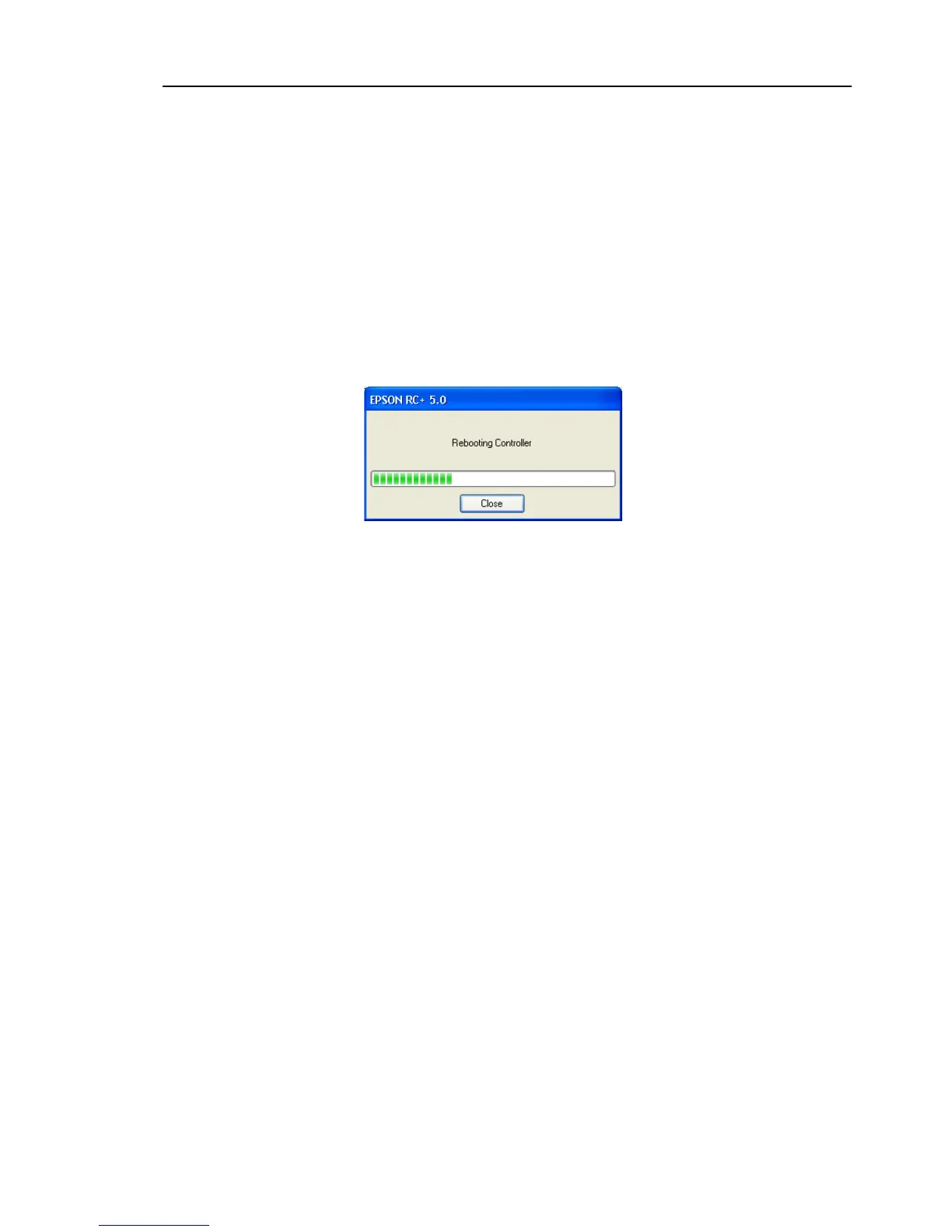

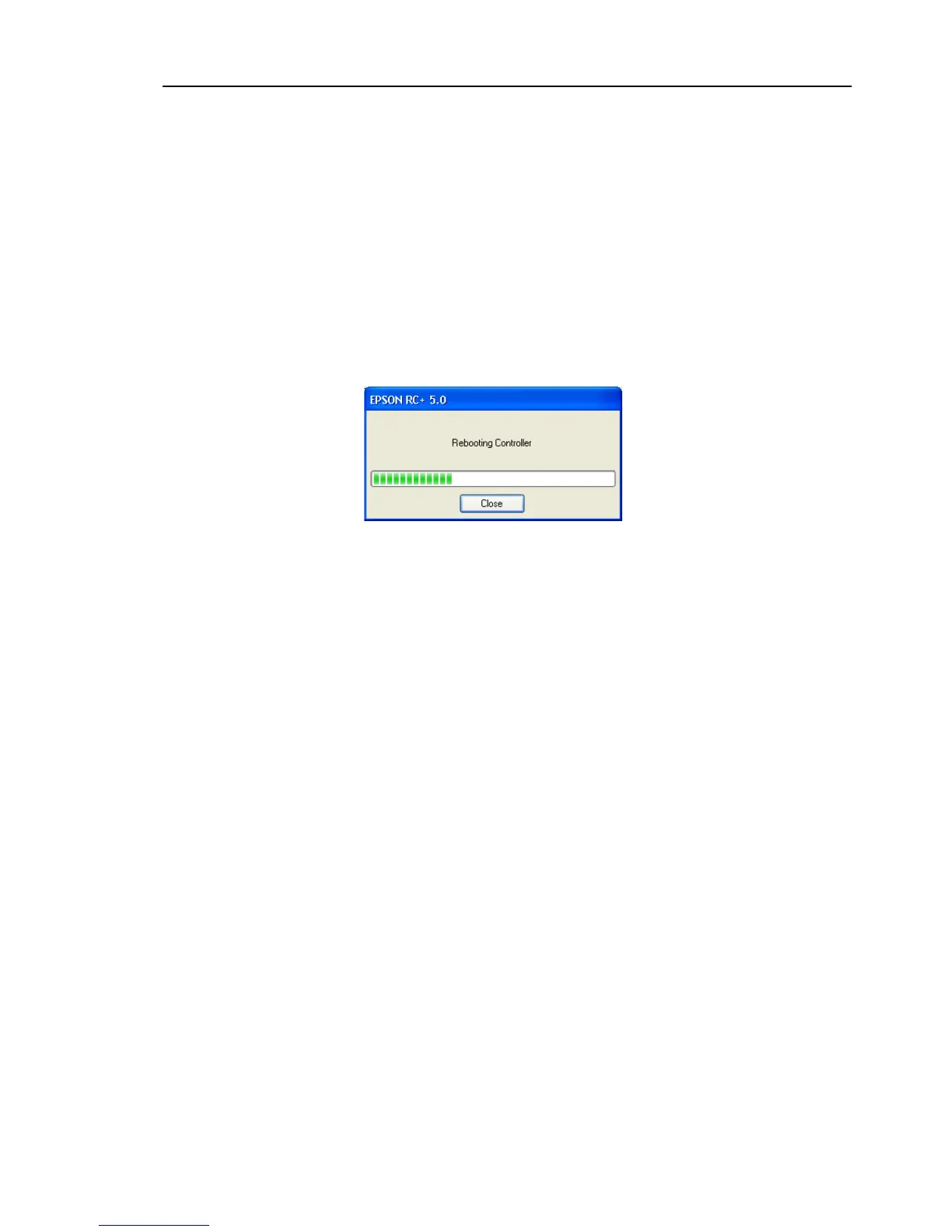

-5 Reboot the Controller.

Select EPSON RC+ menu-[Tools]-

[Controller] and click the <Reset

Controller> button.

* This window will be disappeared when the Controller starts up.

-1 Execute the following command from the menu-[Tools]-[Command Window].

>calpls 0,0,0,0

* Manipulator does not move.

-2 Execute one of the following commands according to

calibrate from the menu-[Tools]-[Command Window].

Joint #1 >calib 1

Joint #2 >calib 2

Joint #3 >calib 3

Joint #4 >calib 3, 4

-1 Turn ON the motors from the EPSON RC+ menu -[Tools]

-[Robot Manager]-[Control Panel].

Click the <Free All> button to free all joints from servo control. Now, you

the Manipulator by hand to a rough position/posture of the calibration

)-4 Create the data from the calibration point data.

Enter and execute the following command in [Command Window].

(In this example, P1 is used as the calibration point data.)

> Calpls Ppls(P1,1), Ppls(P1,2), Ppls(P1,3), Ppls(P1

Loading...

Loading...