31

Chapter 2 Setup

Adjusting the Paper Roll Near-End Sensor

Below are two situations where a roll paper NE sensor adjustment is required.

• To adjust the detection position to suit the diameter of the roll paper core used.

• To adjust the detection position of remaining amount of paper.

Follow the steps below to adjust the roll paper near-end sensor.

1

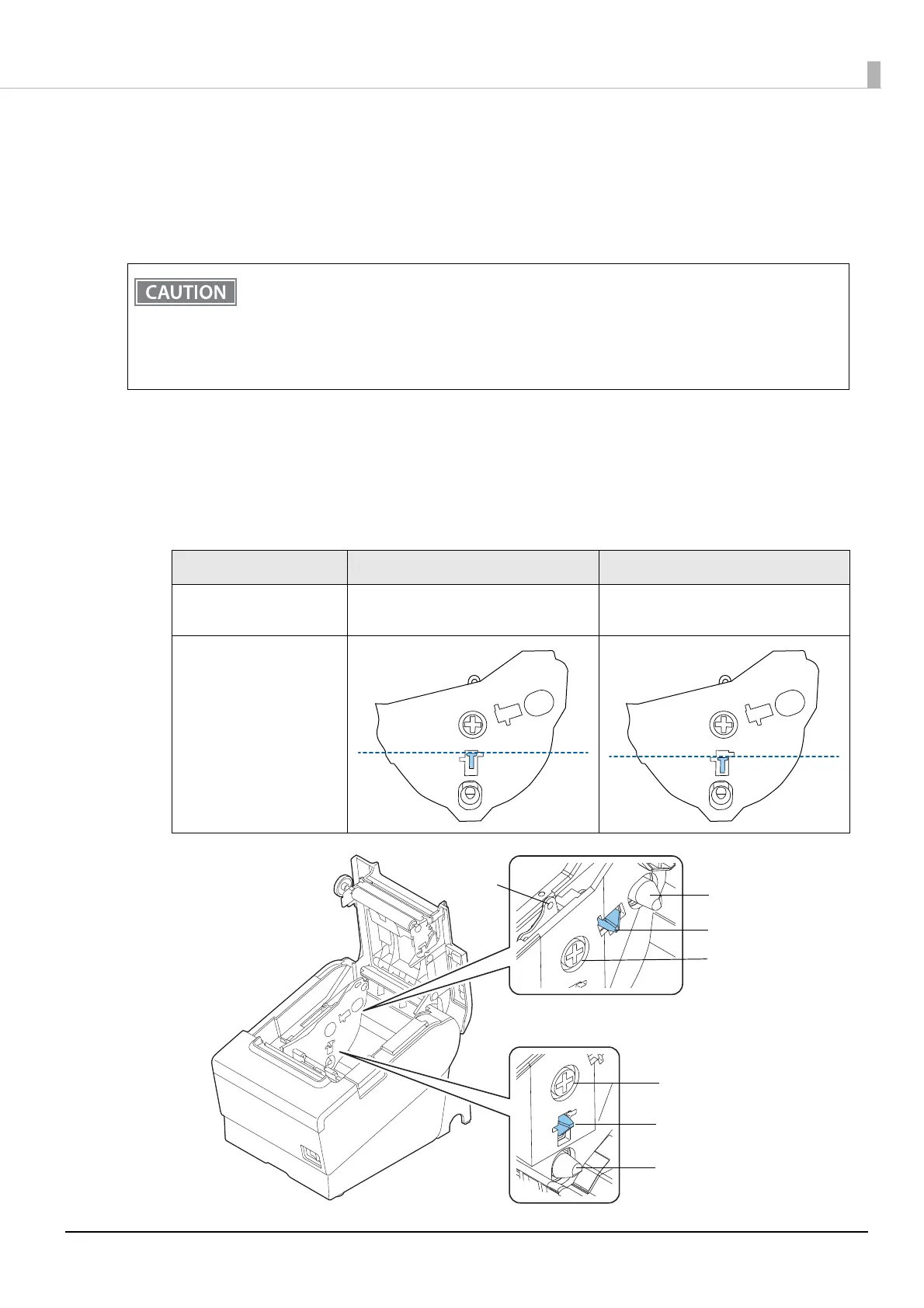

Open the roll paper cover, and remove the roll paper.

2

Loosen the adjustment screw fastening the sensor, and then operate the knob to

align the top edge of the positioning plate with the upper or lower level.

• Since roll paper cores vary slightly in shape, depending on paper roll design and manufacturing

tolerances, it is impossible to detect the remaining paper exactly.

• To let the NE sensor detect remaining amount of paper accurately, it is recommended to use a roll

paper with a core inner diameter of 12 mm {0.47"} and outer diameter of 18 mm {0.71"}.

• An outer diameter of a paper roll that is detected as near-end varies by usage environment, and/or

paper specifications. Please check operation of the NE sensor by yourself.

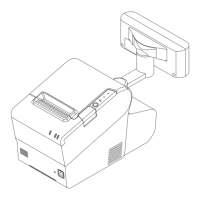

Adjustment position Upper Lower

Outer diameter of a roll to

be detected as near-end

Approx. 27 {1.06"} Approx. 23 {0.97"}

Position of the positioning

plate

Detection lever

Positioning plate

Adjustment screw

Adjustment screw

Positioning plate

Detection lever

For wall-hanging

For horizontal installation

Knob

Loading...

Loading...