6 CONTROL PANEL

0463 933 001

- 21 -

© ESAB AB 2023

MENU

There are basic functions in the menu feature. To access the functions,

press the parameter selection button until the MENU symbol is ON. The

left display shows a letter and the right display shows a value. Select the

function by pressing the same button. The knob (4) is used to change the

value of the selected function. The knob (3) is used to change the different

functions.

NOTE!

The list of MENU functions will vary depending on the application

selected.

Left potentiometer knob (3)

In MIG (GMAW/FCAW) mode, the knob is used to adjust the output voltage of the unit. In Manual

MIG Mode, the setup chart is attached to the Wirefeeder compartment door.

In the Parameter selection state, adjusting the left knob (3) will select the different feature and the

name will shows on the left LED.

Right potentiometer knob (4)

The right knob (4) adjusts the amount of welding current delivered by the power source. In MMA

modes, the knob directly adjusts the power inverter to deliver the desired level of output current.

In MIG (GMAW/FCAW) mode, the right knob adjusts the speed of the wire feed motor. The optimum

Wire feed speed required will be dependent on the type of welding application. the setup chart is

attached to the Wirefeeder compartment door.

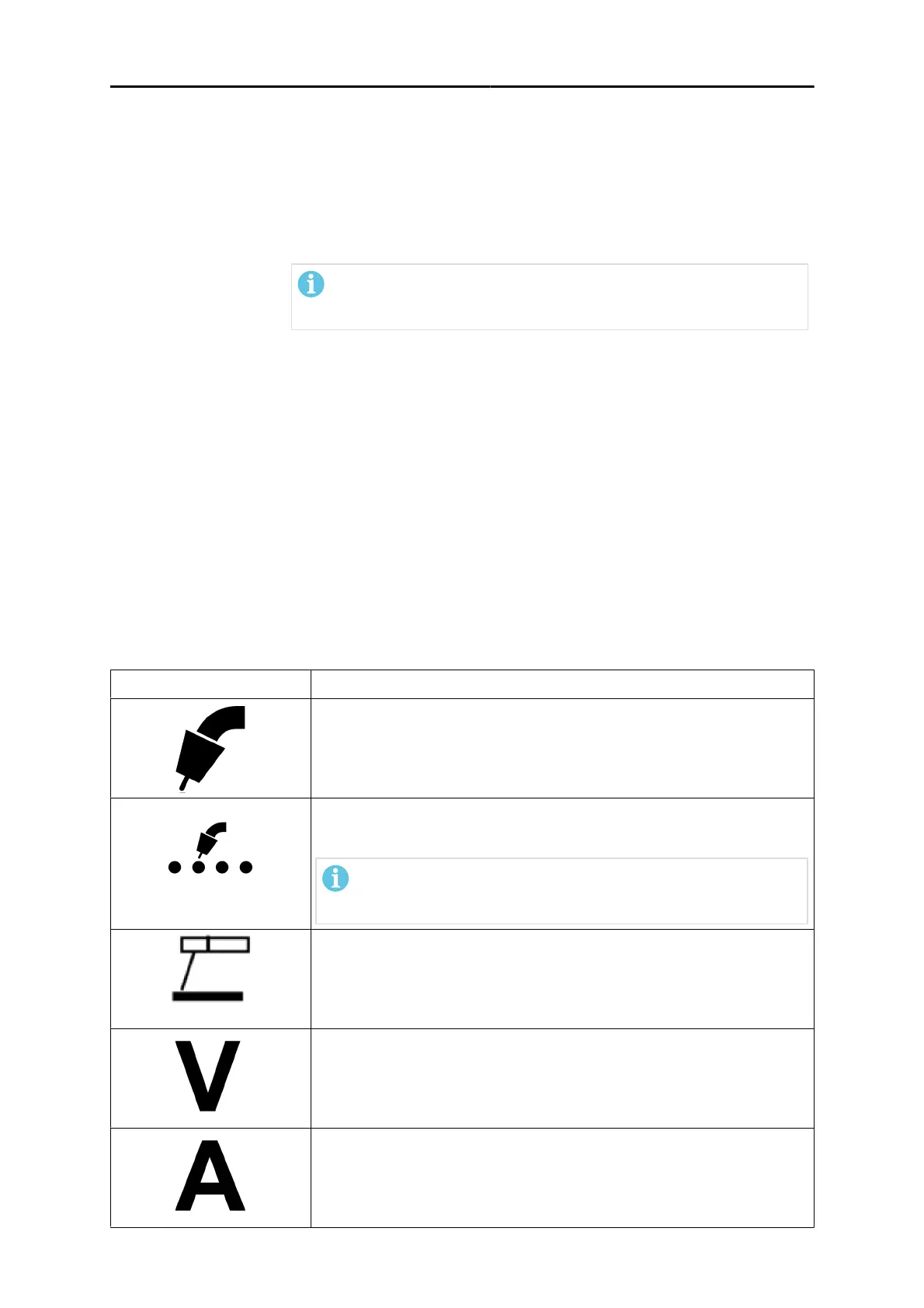

6.2 LED indicators description

Indicator Description

MIG/MAG

Constant voltage control process is where the set voltage and the wire

feed speed are set independent of each other.

MIG/MAG SPOT

Spot welding is used when you want to spot weld thin plates together.

NOTE!

It is not possible to shorten the welding time by releasing the

trigger switch.

MMA

MMA welding may also be referred to as welding with coated

electrodes. Striking the arc melts the electrode, and its coating forms

protective slag.

Measured voltage

Measured value in the display for welding voltage V is an average

numerical value which is calculated during the welding excluding the

weld termination.

Measured amperage

Measured value in the display for welding current A is an average

numerical value which is calculated during the weld excluding the weld

termination.

Loading...

Loading...