5 OPERATION

0463 933 001

- 18 -

© ESAB AB 2023

3) Insert a new wire spool into the unit and straighten out the new welding wire 10–20cm. File away

burrs and sharp edges from the end of the wire before inserting it into the feeder mechanism.

4) Lock the wire spool onto the brake hub, by tightening the brake hub nut.

5) Thread the wire through the feeder mechanism.

NOTE!

Replace the brake hub nut and the brake hub sleeve if they are worn out and do not lock

properly.

6) Close and lock the left door of the wire feeder.

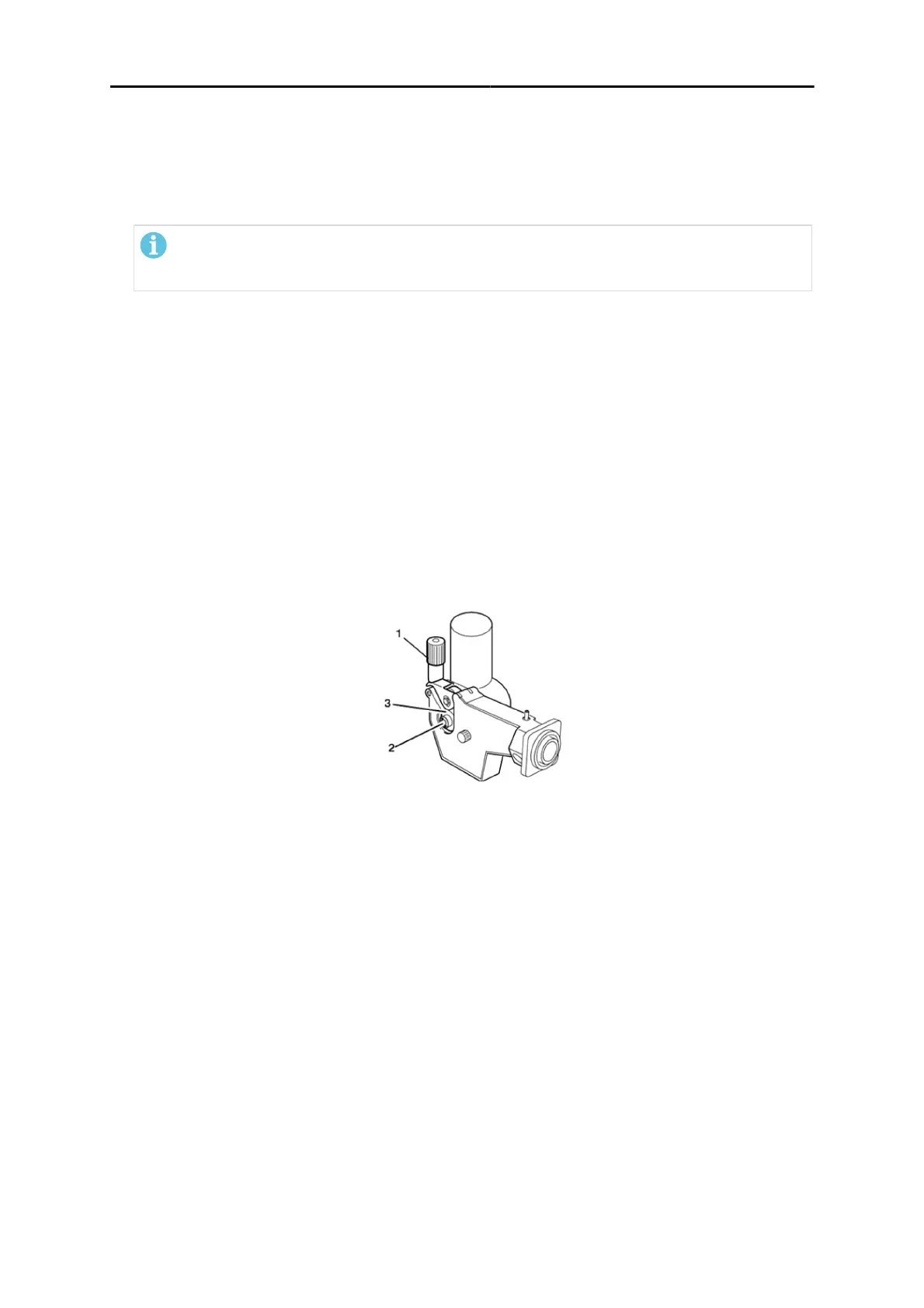

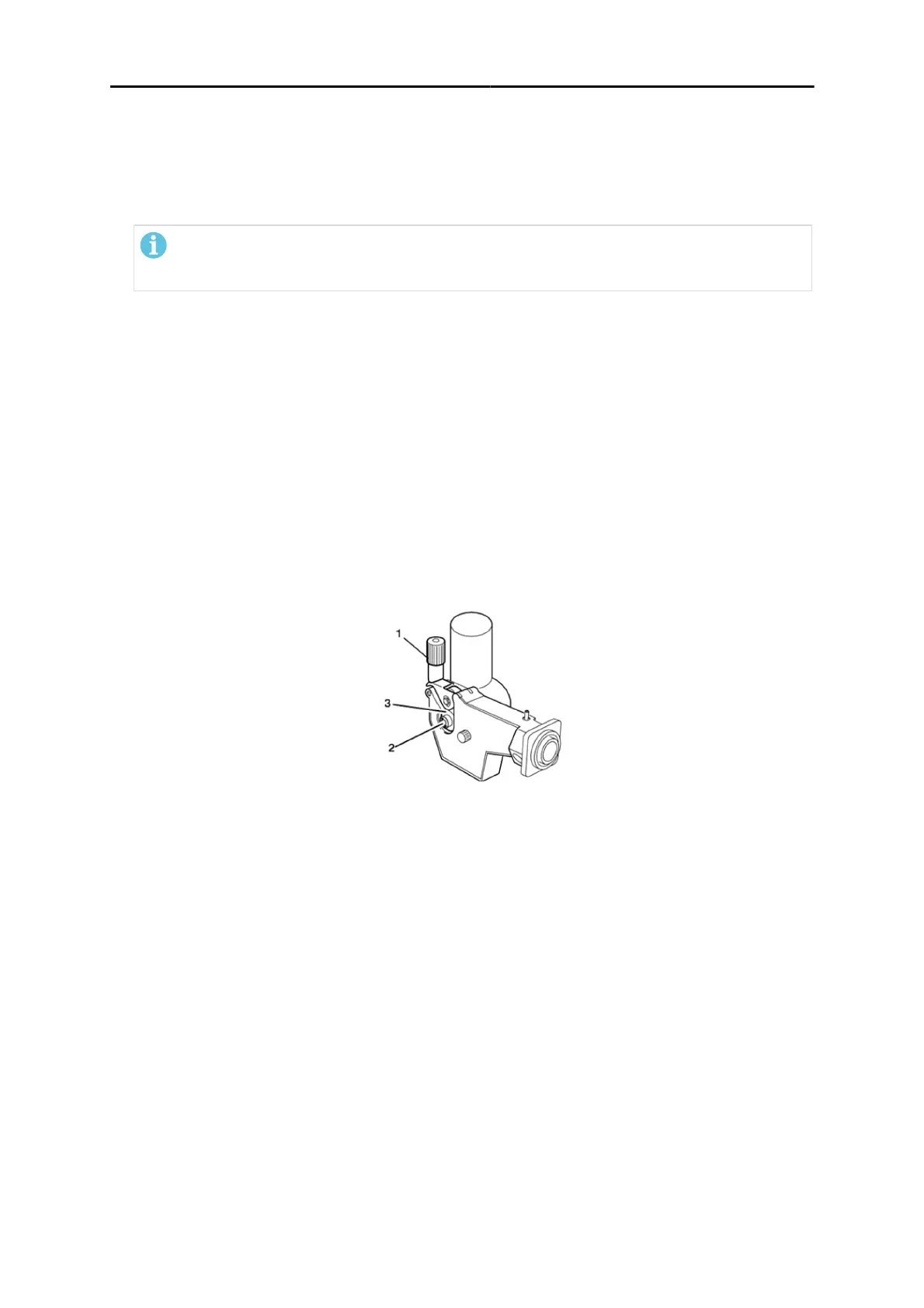

5.8 Changing feed rollers

When changing to a different type of wire, the feed rollers should be changed to match the new type of

wire. For information about correct feed roller depending on wire diameter and type, see the WEAR

PARTS appendix.

1) Open the side panel.

2) Disconnect the pressure sensor (1) by folding it backwards.

3) Disconnect and remove the Allen screw (2) and the washer.

4) Pull out the feed roller (3).

During installation, repeat the steps above in reverse order.

Choice of track in the feed roller.

Turn the feed roller with the dimensioning mark for the required track towards you.

5.9 Roller pressure

The roller pressure should be adjusted separately on each tensioner unit, depending on used wire

material and diameter.

Start by making sure that the wire moves smoothly through the wire guide. Then set the pressure of

the wire feeder's pressure rollers. It is important that the pressure is not too high.

Loading...

Loading...