6 CONTROL PANEL

0463 933 001

- 25 -

© ESAB AB 2023

Material selection button

This is used to select welded base material for optimal characteristics in the internal control panel.

Wire diameter selection button

This is used to select the diameter of the installed wire in the internal control panel.

Wire inching and gas purge button

Wire inching is used to feed wire without welding voltage being applied. The wire is fed as long as

the button is pressed. This function is active in MIG applications only.

Gas purging is used while measuring the gas flow or for flushing any air or moisture from the gas

hoses before welding starts. Gas purging occurs for 15 seconds when the gas purge button or torch

trigger is pressed or until it is pressed again. Gas purge occurs without voltage or wire feed start.

This function is active in MIG applications only.

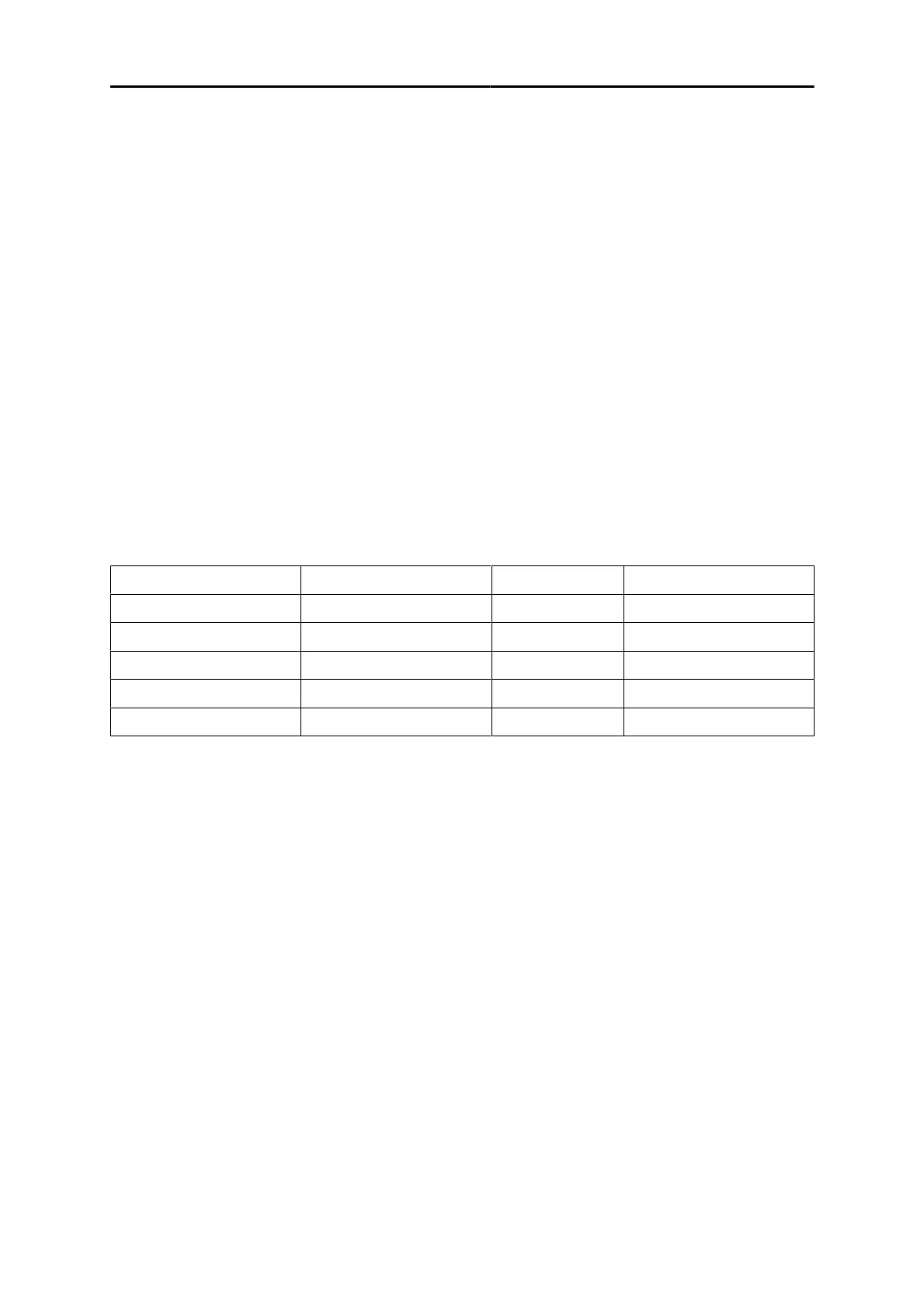

6.4 Menu selection

6.4.1 MIG/MAG

In MIG mode, press the parameter selection button three times to navigate to MENU option. Select the

desired welding function one after other by turning the left potentiometer knob and adjust the desired

value by turning the right potentiometer knob.

Left diplay letter Function Default Right display settings

B-B Burnback 0.1 0.01-0.35

CRA Crater fill time 0 0.0-9.9

PRG Pre-flow 0.1 0.5-9.9

POG Post-flow 0.5 0.5-9.9

RIN Creep start (Run in) ON ON/OFF

Burnback (B-B)

Burnback time is a delay between the time when the wire starts to brake until the time when the

power source switches off the welding voltage.

Too short burnback time results in a long wire stick out after completion of welding, with a risk of the

wire being caught in the solidifying weld pool.

Too long a burnback time results in a shorter stick out, with increased risk of the arc striking back to

the contact tip.

Crater fill (CRA)

Crater filling makes a controlled reduction in the heat and size of the weld pool possible when

completing the weld. This makes it easier to avoid pores, thermal cracking and crater formation in the

weld joint.

Pre/flow (PRG)

Pre-flow controls the time during which shielding gas flows before the arc is struck.

Post/flow (POG)

This controls the time during which shielding gas flows after the arc is extinguished.

Creep start (RIN)

Creep start feeds out the wire at a low wire feed speed until it makes electrical contact with the

workpiece.

Loading...

Loading...