155

ELECTRICAL AND IGNITION

TIMING ADJUSTMENTS

7

Rotate the flywheel clockwise until the piston

contacts the tool. Mark the flywheel directly across

from the pointer. Label this mark “B.” Rotate fly-

wheel counterclockwise slightly to release tool

then remove it from spark plug hole.

Use the cast in markers on the flywheel to calcu-

late the exact center between marks “A” and “B.”

Mark and label the center point “C.”

If mark “C” and the cast-in TDC boss on flywheel

are in alignment, the timing pointer is in the cor-

rect location.

If the pointer alignment is NOT correct, rotate the

flywheel clockwise to align the mark “C” with the

pointer. Hold the flywheel in this position. Loosen

the pointer retaining screw and adjust the pointer

location to align with the cast-in TDC boss on the

flywheel. Tighten retaining screw.

Repeat the entire adjustment process to make

sure pointer is aligned correctly.

Install spark plugs. Refer to Spark Plug Indexing

on p. 84.

Timing Verification

Use Evinrude Diagnostics software to synchronize

the mechanical timing of the outboard with the

electronic timing of the EMM.

Check ignition timing after any of the following

procedures:

• Powerhead replacement

• Crankshaft replacement

• Flywheel removal or replacement

• CPS replacement

• EMM replacement

• EMM software replacement (reprogramming)

IMPORTANT: Make sure the timing pointer is

set and the outboard reaches operating tempera-

ture before timing verification is performed.

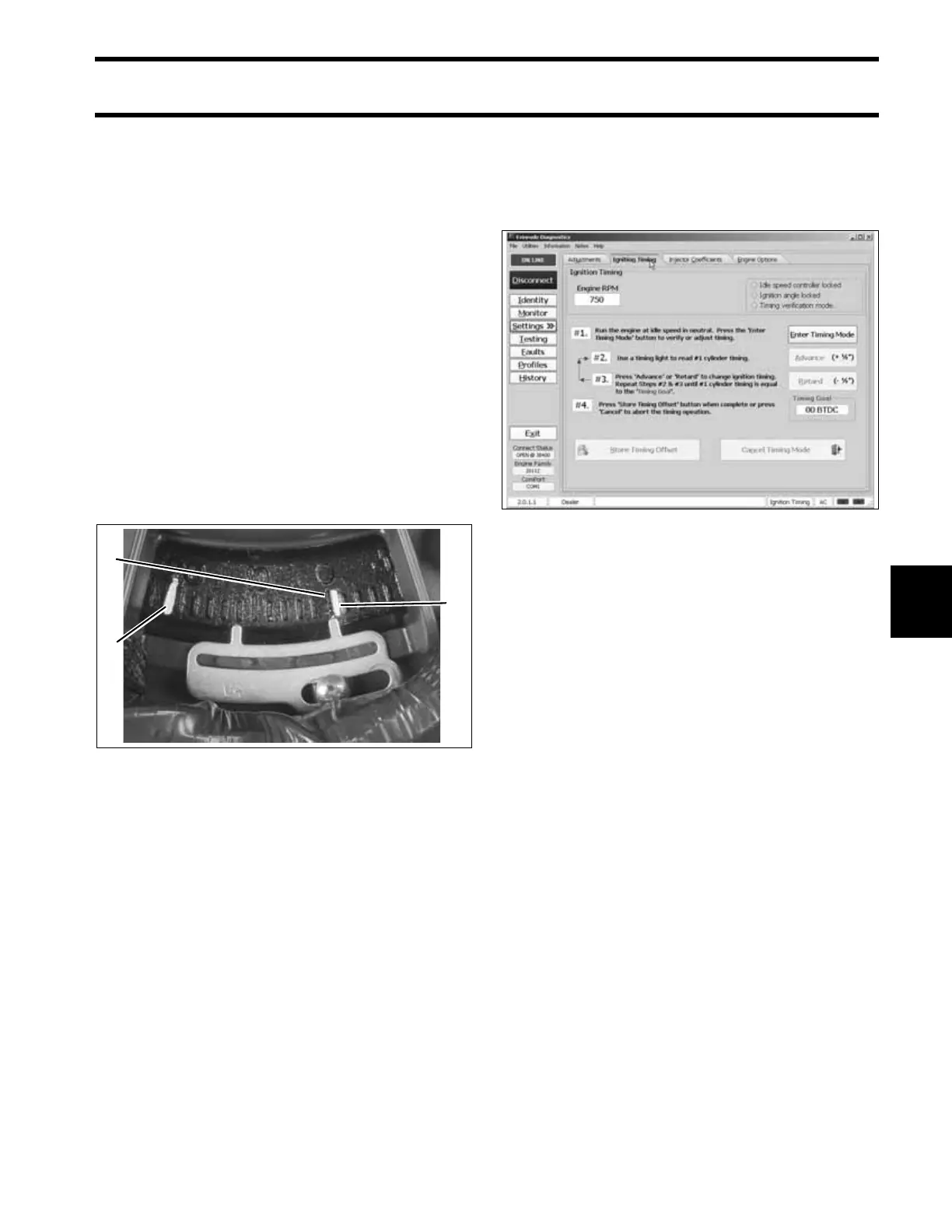

1. Cast in TDC mark

2. Mark B

3. Mark C

005388

3

1

2

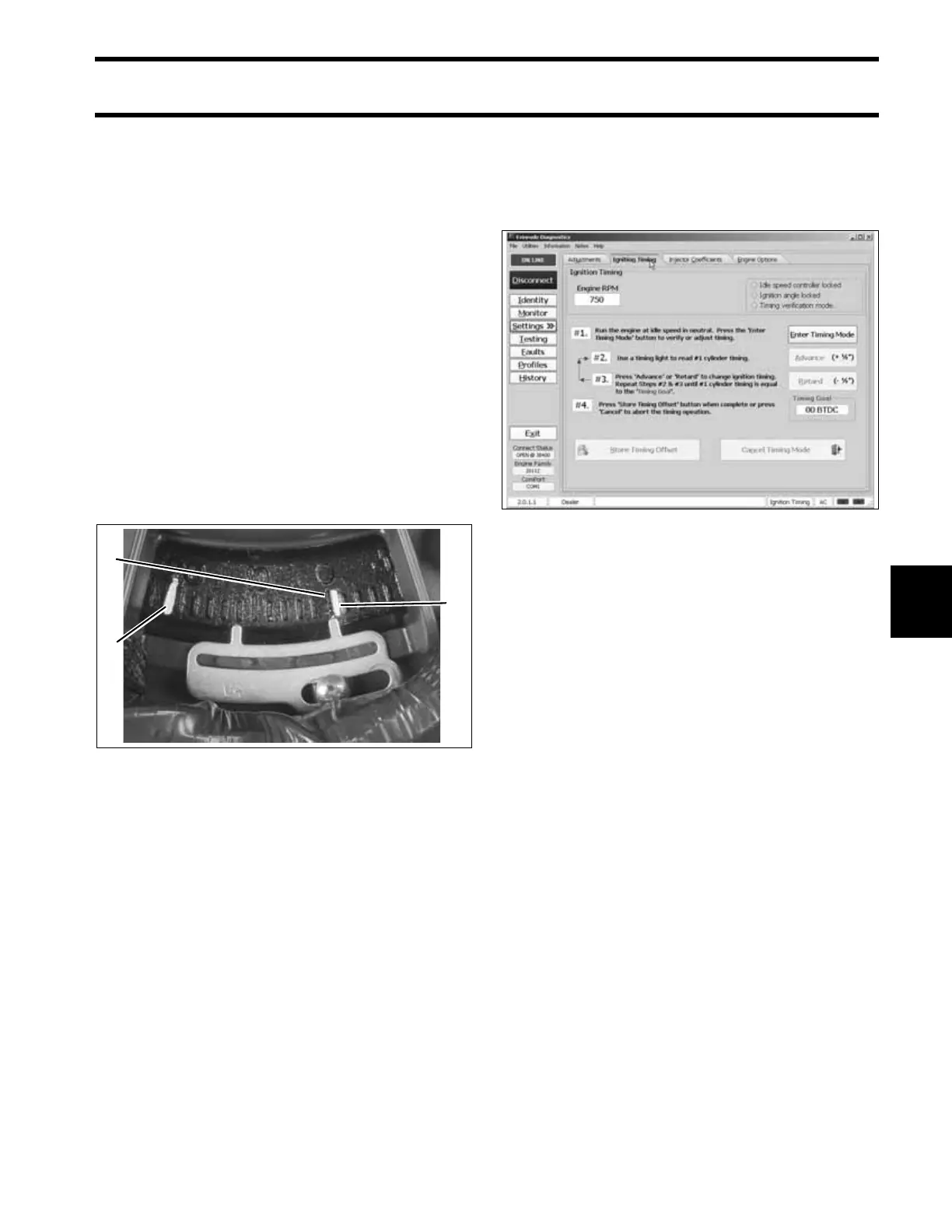

Timing Adjustment Screen 006547

Loading...

Loading...