31

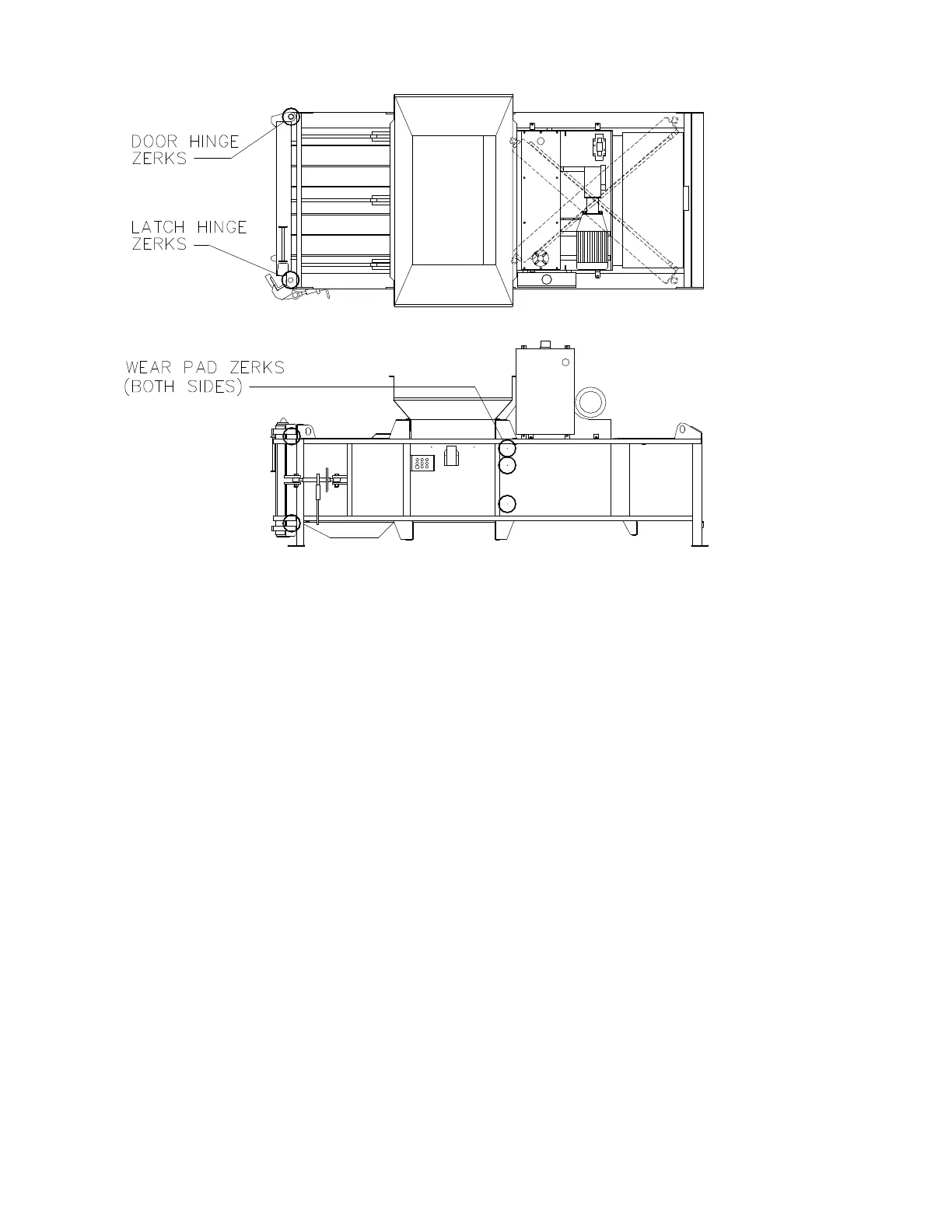

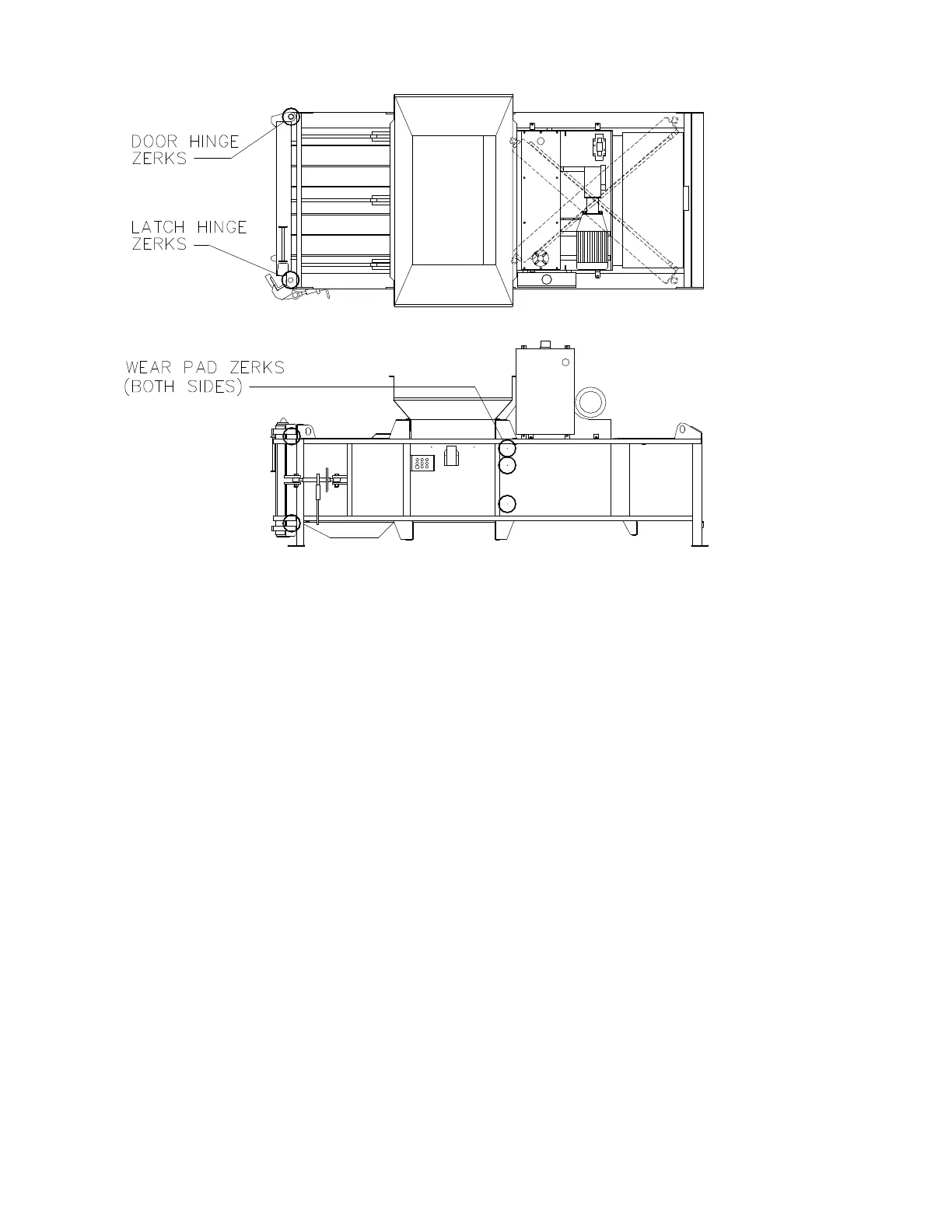

Diagram L. Lubrication Chart.

9. Check that the bale tie light works when a bale is complete.

10. Test the door safety interlock. The motor should stop and the pressure to the platen decompresses if the latch is opened. The

motor will not run if the door is not swung completely open when ejecting a bale.

11. Inspect the turnbuckle condition. Make sure bolts are secure.

12. Inspect the door latch. Check general condition, welds and structure. Inspect the hinge pins for wear.

13. Inspect the door of the baler. Check general condition, welds and structure. Inspect the hinge pins for wear.

14. Lock out the baler power disconnect, open the baler door and clean the wire tie slots in the front of the platen.

15. Clean the wire guides.

16. Check the clean out tool, this may be required more often for high usage situations.

17. Inspect the platen wiper condition and make sure it pivots freely.

18. Inspect the condition of the dogs. The dogs should pivot freely.

19. Check all nuts and bolts. Make sure all are tight and secure.

20. Walk around baler and inspect overall condition of equipment, including decals and structural. Make sure overall baler is clean

and free of debris.

21. Check to see that all access covers are secured in place.

Loading...

Loading...