30

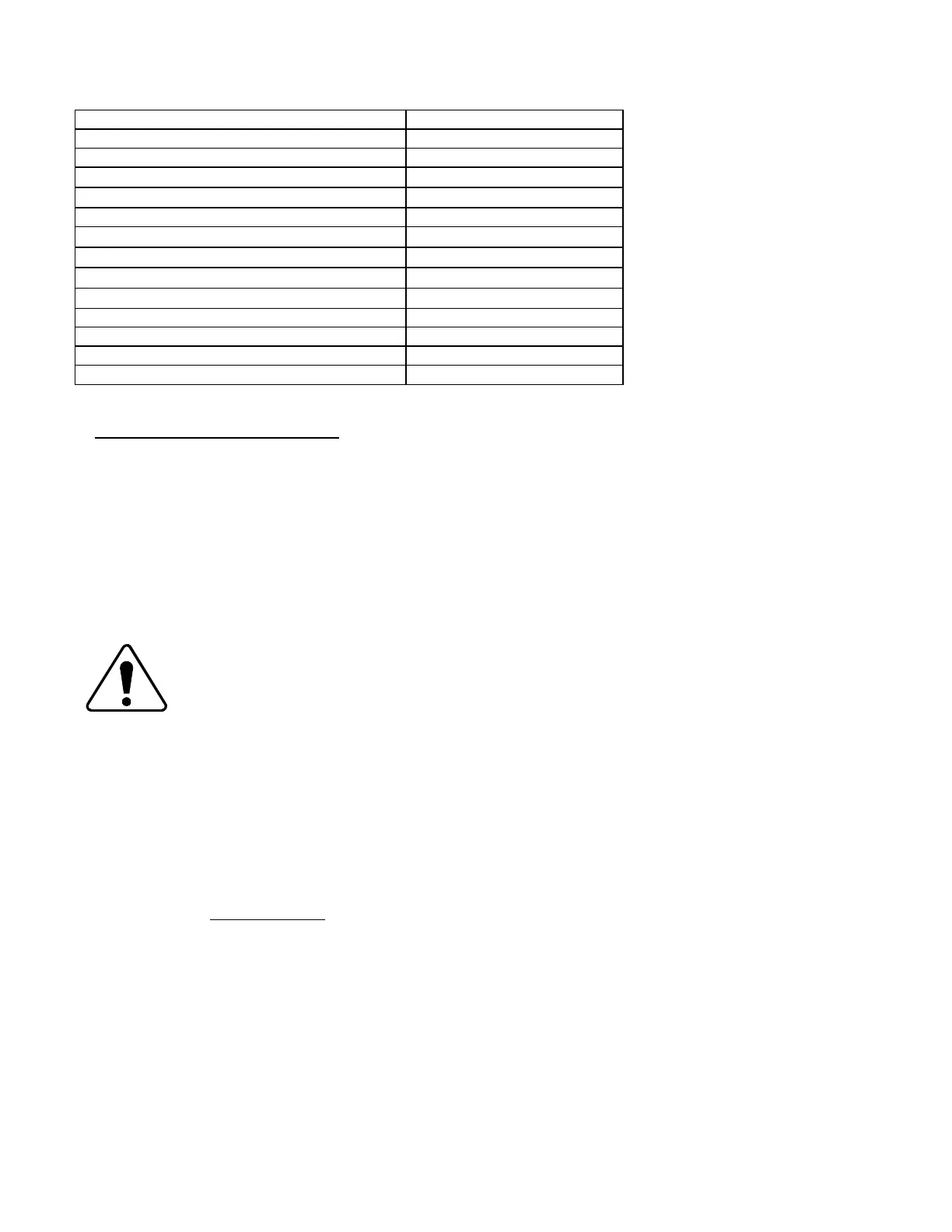

OIL SELECTION TABLE

Oxidation Control (ASTM D

Pour Point, (°F), max.

Flash Point, (°F), min.

SUS at 100°F

SUS at 210°F

cSt at 40°C

cSt at 100°C

Foam Test, ASTM D892 I, II, III,ml/ml, max.

Alternate Oils include: Exxon Univis M32, Texaco Randall HD-36, Mobil DTE-13M

WEEKLY CARE REQUIREMENTS

1. Check the baler disconnect switch for function. Make sure a padlock is available for servicing.

2. Check the hydraulic reservoir oil level. The oil level in the sight gauge on the side of the reservoir should be at the oil level

arrow when the platen is fully retracted. If it is not, add oil as specified in the table above.

3. Grease the six nylatron wear pads at the sides (three per side) of the baler. Also grease the two door latch hinges and two door

hinges. See the Diagram L. on the next page for grease point locations. Lubricate the baler every 35 to 40 hours of operation.

High use will require lubrication more often.

4. Check hydraulic pump, valve, cylinders and hoses for leaks. Check for any damage, kinks, etc.

Use cardboard or wood to search for suspected leaks. Do not use hands. High pressure fluid flow can penetrate

skin and cause serious injury.

5. Inspect the power unit. Remove dust and dirt from outside of the reservoir, control box, and electrical enclosure. Wipe off any

grease, oil, or moisture. Inspect motor for excessive dirt, friction, or vibration. Keep the ventilation openings clear to allow free

passage of air.

6. Remove the rear cover and clean out behind the platen. Clean off the limit switch rails.

7. Inspect the limit switches and rail. Make sure the arms are 90 degrees from the body and that all connections are secure. Inspect

the cylinders, inspect and grease cylinder pins, etc.

8. Test all the baler controls and make sure each is operating properly. Check the photo eye operation. See the description of each

control under Operating Controls in the OPERATING INSTRUCTIONS section.

Loading...

Loading...