Maintenance

surfaceoftherubberseal.Turnlterclockwise

untilrubbersealcontactsthelteradapterthen

tightenlteranadditional1/2to3/4turn.

6.Cleanaroundoilllcapandremovecap.Fillto

speciedcapacityandreplacecap.

7.Removedrainhose,closefueltank,andlower

hopper.

8.UseoilrecommendedintheCheckEngineOil

Levelsection.DoNotoverll.Starttheengine

andcheckforleaks.

9.Wipeupanyspilledoilfromenginedeck

mountingsurfaces.

CheckHydraulicOilLevel

ServiceInterval:Every40hours

WARNING

Oilspilledorventedfromanoverlledhydraulic

reservoirontothePTObrakebandwillcausea

longerstoppingtimeforthedeckandblower

rotatingcomponents.Thedeckandblower

rotatingcomponentscancauseseriousinjury.

•Waitforallmovingpartstocometoa

completestopbeforeservicing.

•DoNotoverllthehydraulicreservoir.

Carefullyllonlytotherecommendedlevel.

•Replacethebrakebandifitbecomes

contaminatedwithoil.

1.Stopengineandwaitforallmovingpartstostop.

Engageparkingbrake.

2.Waituntiltheunitcoolsbeforecheckingthe

hydraulicoil.

3.Tilthopperup.

4.Cleanareaaroundhydraulicreservoircapand

removecap.

5.Wipethedipstickcleanandre-insertthecapback

intothehydro.Lightlytightenthecap.

6.Removethecapagainandcheckthelevelofthe

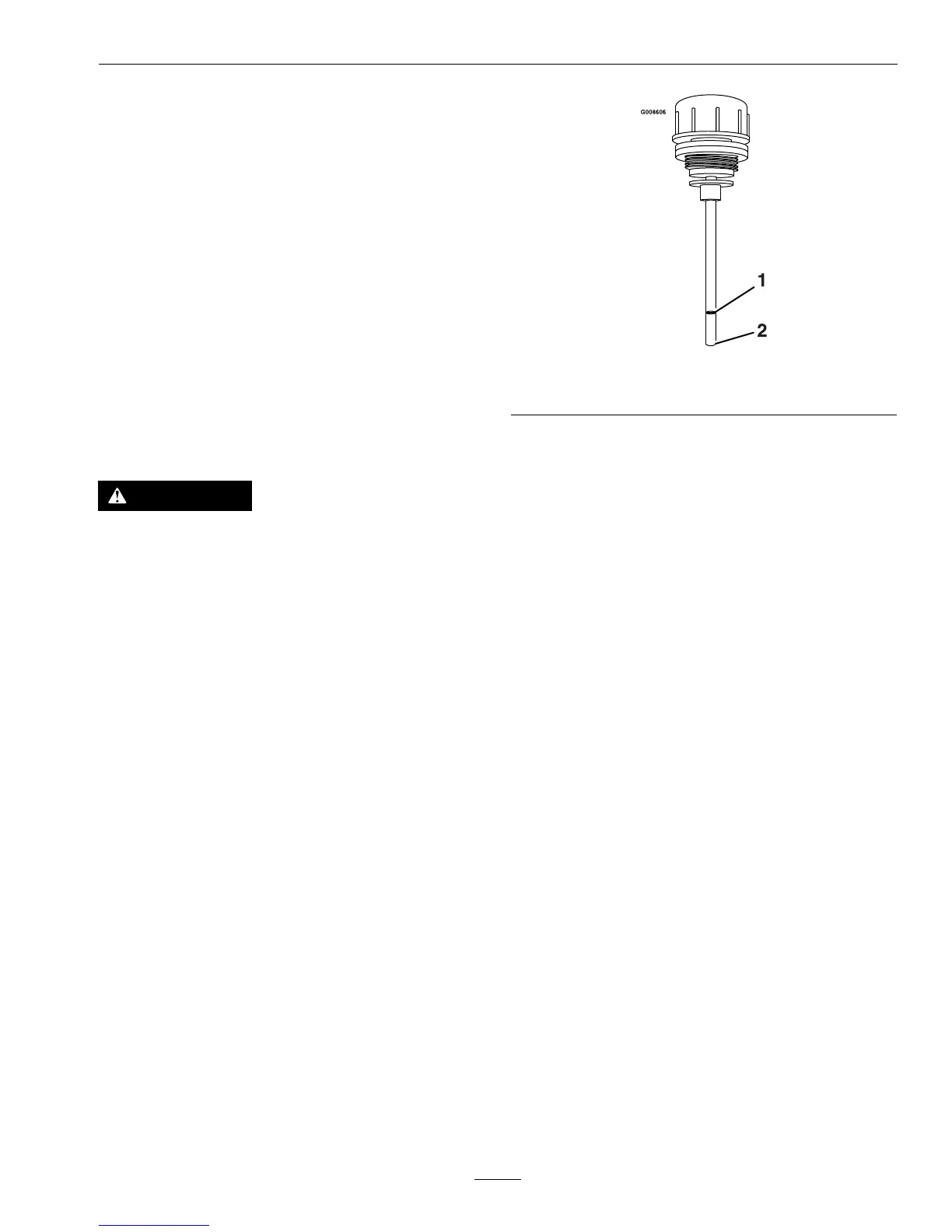

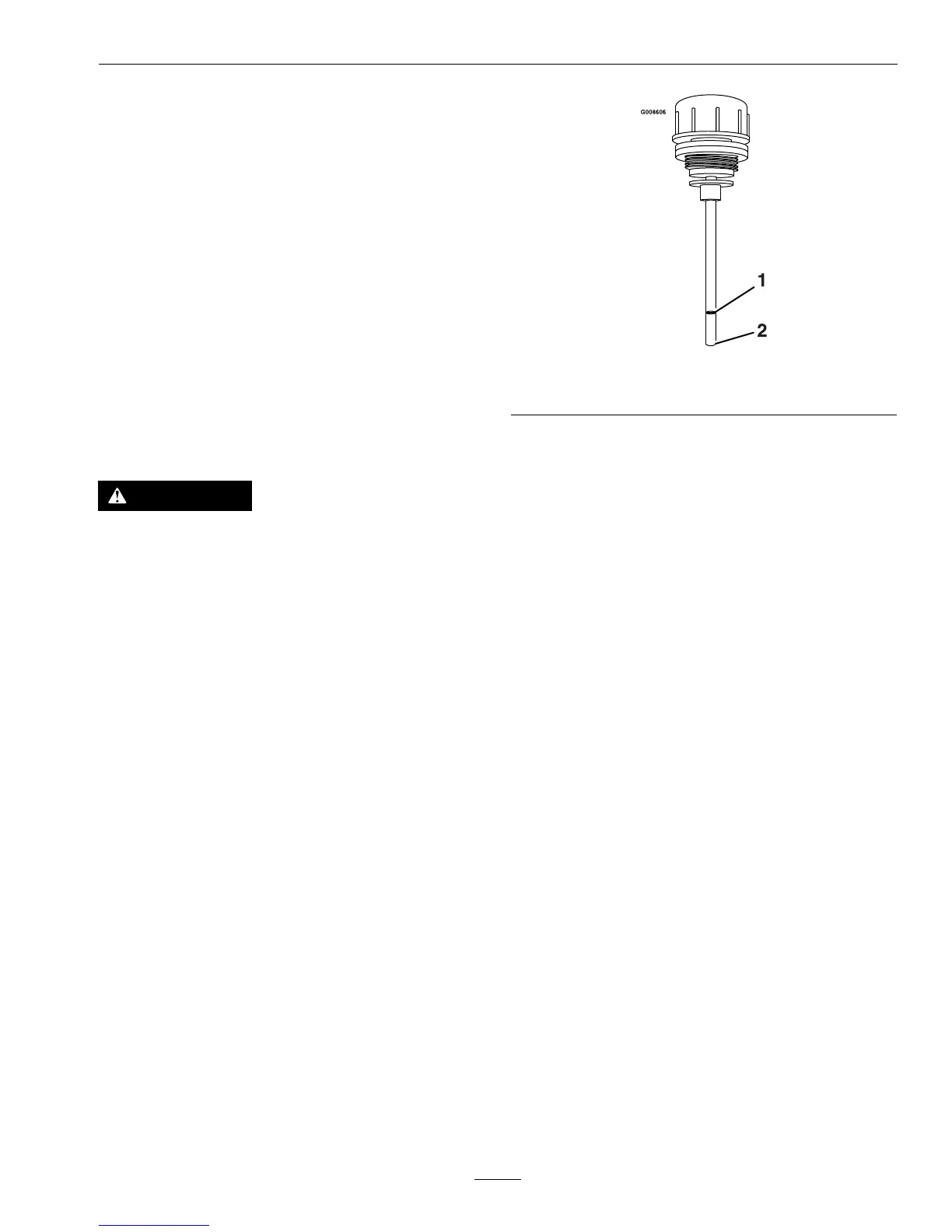

oilonthedipstick.SeeFigure19foroillevels.

Figure19

1.Full2.Add

Note:Theoillevelonthedipstickwillbe

incorrectiftheoilischeckedwhentheunitishot.

7.Ifthedipstickoilleveldoesnotregisteronthe

dipstick,addExmarkPremiumHydroOil.Do

Notoverll.

8.Replacehydraulicreservoircapandtightenuntil

snug.DoNotovertighten.

CheckTirePressures

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto15psi(103kPa).

4.Therearcastertireissemi-pneumaticanddoes

notneedtobeinated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.TilthopperupandcheckpumpandPTOdrive

beltsforwear,cracking,orcontamination.

3.Beltsarespringtensionedandnoadjustmentis

necessaryunlessbeltsarereplaced.SeePTO

35

Loading...

Loading...