Maintenance

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Carefullycleanareaaroundlter.Itisimportant

thatnodirtorcontaminationenterhydraulic

system.

3.Unscrewltertoremoveandallowoiltodrain

fromreservoir.

Important:Beforereinstallingnewlter,ll

itwithExmarkPremiumHydrooilandapply

athincoatofoilonthesurfaceoftherubber

seal.

Turnlterclockwiseuntilrubbersealcontactsthe

lteradapter,thentightenthelteranadditional

2/3to3/4turn.

4.FillreservoirasstatedinCheckHydraulicOil

Levelsection.

ExmarkPremiumHydroOilisrecommended.

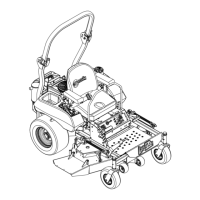

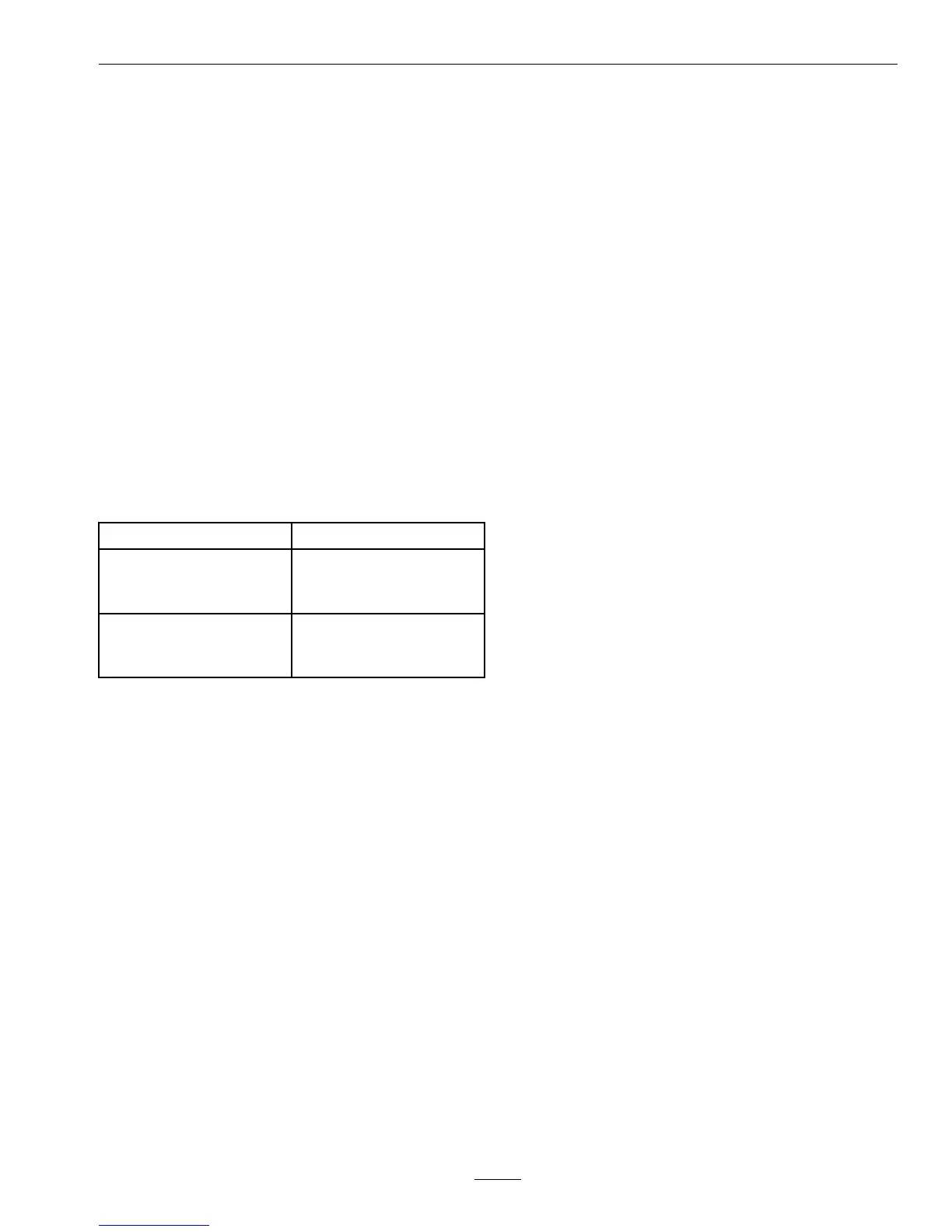

Refertothechartforanacceptablealternative:

HydroOil

ChangeInterval

ExmarkPremiumHydro

Oil(Preferred)

Afterrst100hours

*Every500hours/yearly

thereafter

Mobil115W50Afterrst100hours

*Every250hours/yearly

thereafter

*Mayneedmoreoftenundersevereconditions.

5.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

6.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

leverstothefullspeedandrunforseveral

minutes.Shutdownmachineandrecheckoil

level.

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

CheckWheelHubLocknuts

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Torqueto275–350ft-lb(373–475N-m).

CheckWheelLugNuts

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Torqueto85-105ft-lb(122-129N-m)crosspattern.

FuelTank—Mounting

HardwareSpecications

ServiceInterval:Asrequired

Wheninstallingthenutsonthefueltankstuds,fully

tightenthenylocnutandbackoff1/2turn.This

allowsfornormalfueltankexpansionandcontraction

withchangesintemperatureandfuellevels.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpdrivesheavesetscrews.

•SquareheadsetscrewsonHydropumpcontrol

arms.

•Sheaveretainingboltintheendofengine

crankshaft,blowershaftandjackshaft.

•Casterwheelspacernuts.

•Fueltankbulkheadttingnuts.

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

Fueltankstuds,wherestudsareinsertedintotank.

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

Dielectricgreaseshouldnotbeappliedtosealed

connectors.

39

Loading...

Loading...