Maintenance

Note:DoNotchangehydraulicsystemoil(except

forwhatcanbedrainedwhenchanginglter),unless

itisfelttheoilhasbeencontaminatedorbeen

extremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

HydraulicSystemAirPurge

ServiceInterval:Asrequired

Airmustbepurgedfromthehydraulicsystem

whenanyhydrauliccomponents,includingoil

lter,areremovedoranyofthehydrauliclinesare

disconnected.

Thecriticalareaforpurgingairfromthehydraulic

systemisbetweentheoilreservoirandeach

chargepumplocatedonthetopofeachvariable

displacementpump(Figure25).Airinotherpartsof

thehydraulicsystemwillbepurgedthroughnormal

operationoncethechargepumpis“primed”.

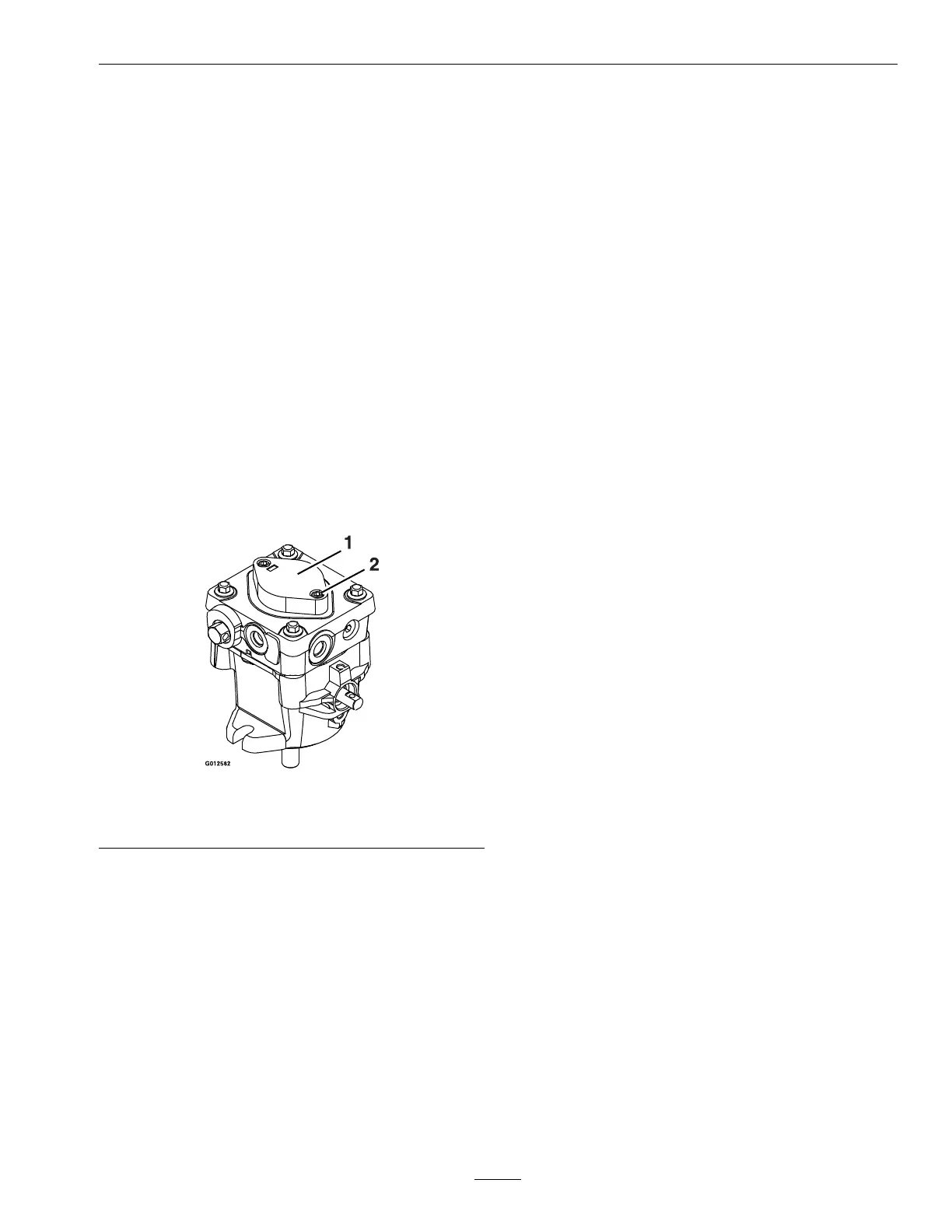

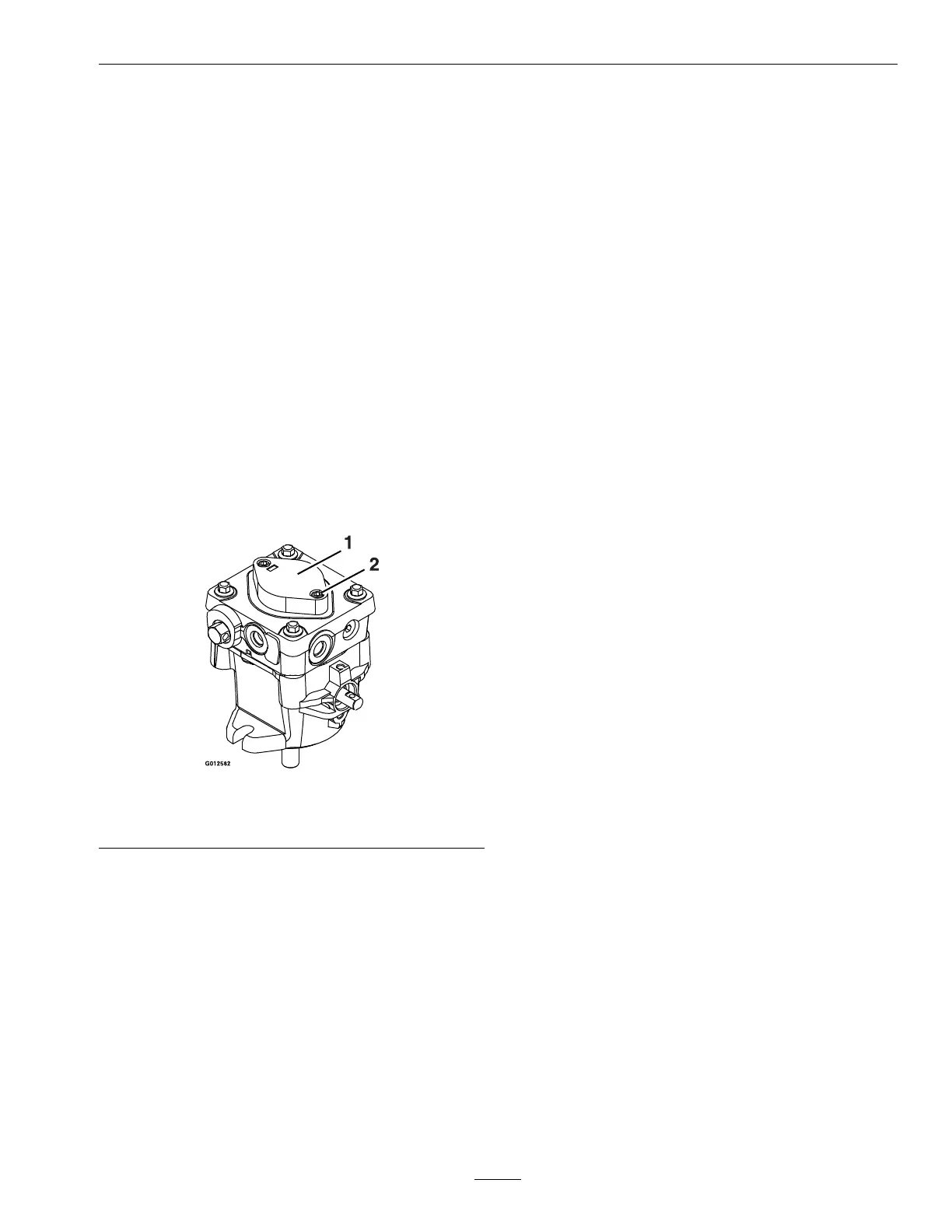

g012852

Figure25

1.Chargepumpcap2.Loosen11/2turnsonly

1.Stopengineandwaitforallmovingpartstostop.

Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

2.CheckoillevelasstatedinCheckHydraulicOil

Levelsection.

3.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movemotioncontrollevers

inward(together)andmovebothleversforward

withequalpressure.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwardposition.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinue

withstep4.

4.Thoroughlycleantheareaaroundeachofthe

chargepumphousings.

5.To“prime”chargepump,loosentwohexsocket

headcapscrews(showninFigure25)11/2turns

only.Makesureengineisnotrunning.Lift

thechargepumphousingupwardandwaitfor

asteadyowofoiltoowoutfromunderthe

housing.Retightenthecapscrews.Dothisfor

bothpumps.

Note:Hydraulicreservoircanbepressurizedup

to5psitospeedthisprocess.

6.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps4and5abovefortherespective

pump.Ifwheelsrotateslowly,thesystemmay

primeafteradditionalrunning.Checkoillevel

asstatedinChecktheHydraulicOilLevel

section.

7.Allowunittorunseveralminutesafterthecharge

pumpsare“primed”withdrivesysteminthefull

speedposition.CheckoillevelasstatedinCheck

theHydraulicOilLevelsection.

8.Checkhydrodrivelinkageadjustmentasstatedin

HydroDriveLinkageAdjustmentsectionin

Adjustments.

WheelHubNutTorque

Specication

ServiceInterval:Aftertherst100hours

Every500hoursthereafter

Torquethenutonthewheelmotortaperedshaftto

115-135ft-lb(156-183N-m).

Note:DoNotuseanti-seizecompoundonthe

wheelhub.

CheckSparkArrester

(ifequipped)

ServiceInterval:Every50hours

37

Loading...

Loading...