Operation

g303981

Figure14

1.Deckheightchange

assistlever

2.Handle

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

positionwhentheheightofcuthaschanged.

1.Stopthemachineandmovethedriveleversto

theneutrallockposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthenylocnut,

springdiscwasher,axleroller,andbolt.

6.Adjustanti-scalprollersfornormaloperating

conditions.Placerollersinoneofthepositions

showninFigure15.Rollerswillmaintain3/4

inches(19mm)clearancetothegroundto

minimizegougingandrollerwearordamage.

Note:ForMaximumDeckFlotation,place

rollersoneholepositionlower.Rollersshould

maintain1/4inch(6.35mm)clearancetoground.

DoNotadjustrollerstosupportthedeck.

Note:Rollermayneedtoberemovedwhen

mowingat1inch(25mm).

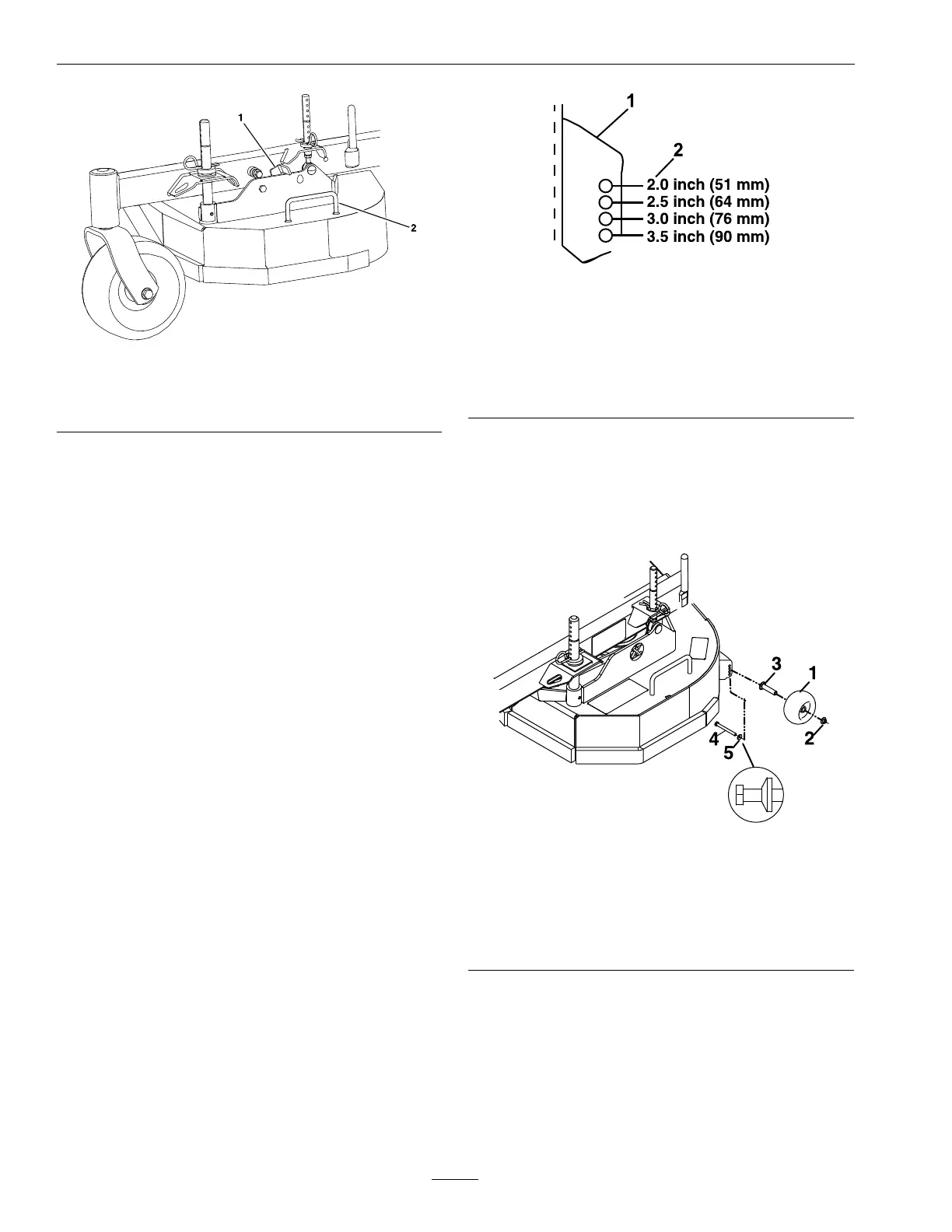

g224809

Figure15

Forcuttingheightsabove3.5inches(38mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

7.Besurerollerboltsareinstalledwiththespring

discwasherbetweenheadoftheboltand

mountingbracket.

8.Torquethe3/8-16nylocnutto50–55ft-lb(68-75

N-m)(Figure16).

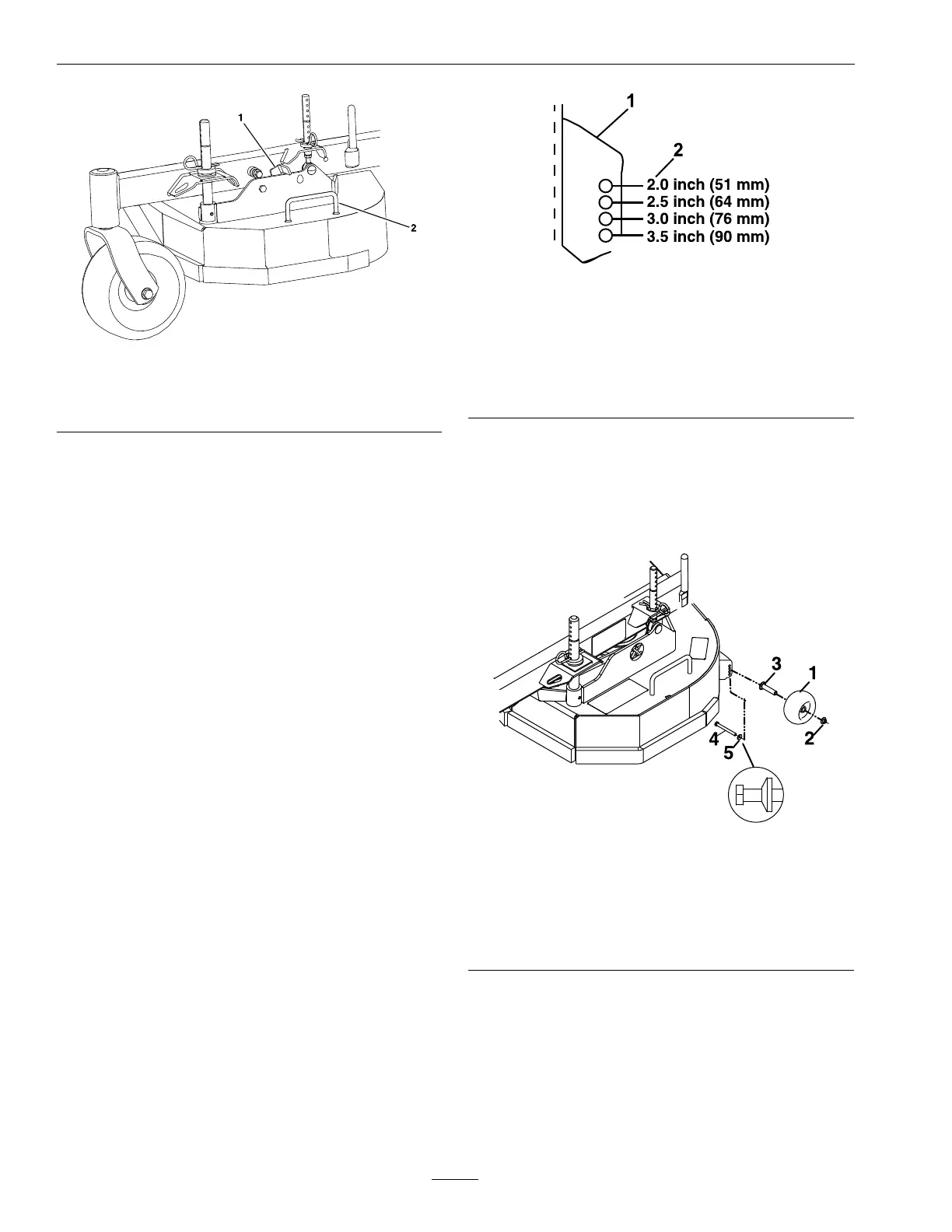

g304045

Figure16

1.Anti-scalproller

4.3/8-16x33/4Grade8

bolt

2.3/8nyloc-torqueto

50–55ft-lb(68-75N-m)

5.Springdiscwasher

(conetowardsbolt)

3.Axleroller

AfterOperation

GeneralSafety

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

24

Loading...

Loading...