UNLESS OTHERWISE STATED, PARTS WHICH HAVE

BEEN PROTECTED BY

THE MANUFACTURER ARE NOT TO BE ADJUSTED BY THE INSTALLER.

Please ensure that any plastic coatings are removed prior to use. Before operation, pan requires to be

thoroughly cleaned and dried.

Discolouration of heated parts is caused by factory

testing to ensure a satisfactory unit. It does not affect

quality or performance.

1.1 MODEL NUMBERS, NETT WEIGHTS & DIMENSIONS.

Pan oil capacity:

18 litres cold, good quality oil (to –MIN- mark)

1.2 SITING

Each unit must be installed on a firm level floor in a well- lit draught free position. The fryer should

be installed in a freestanding position to prevent any possibility of

sideways tipping under force.

The means of restraint may be the manner of installation, such as connection to

a battery of

appliances or installing the fryer in an alcove, or by separate means, such as adequate ties.

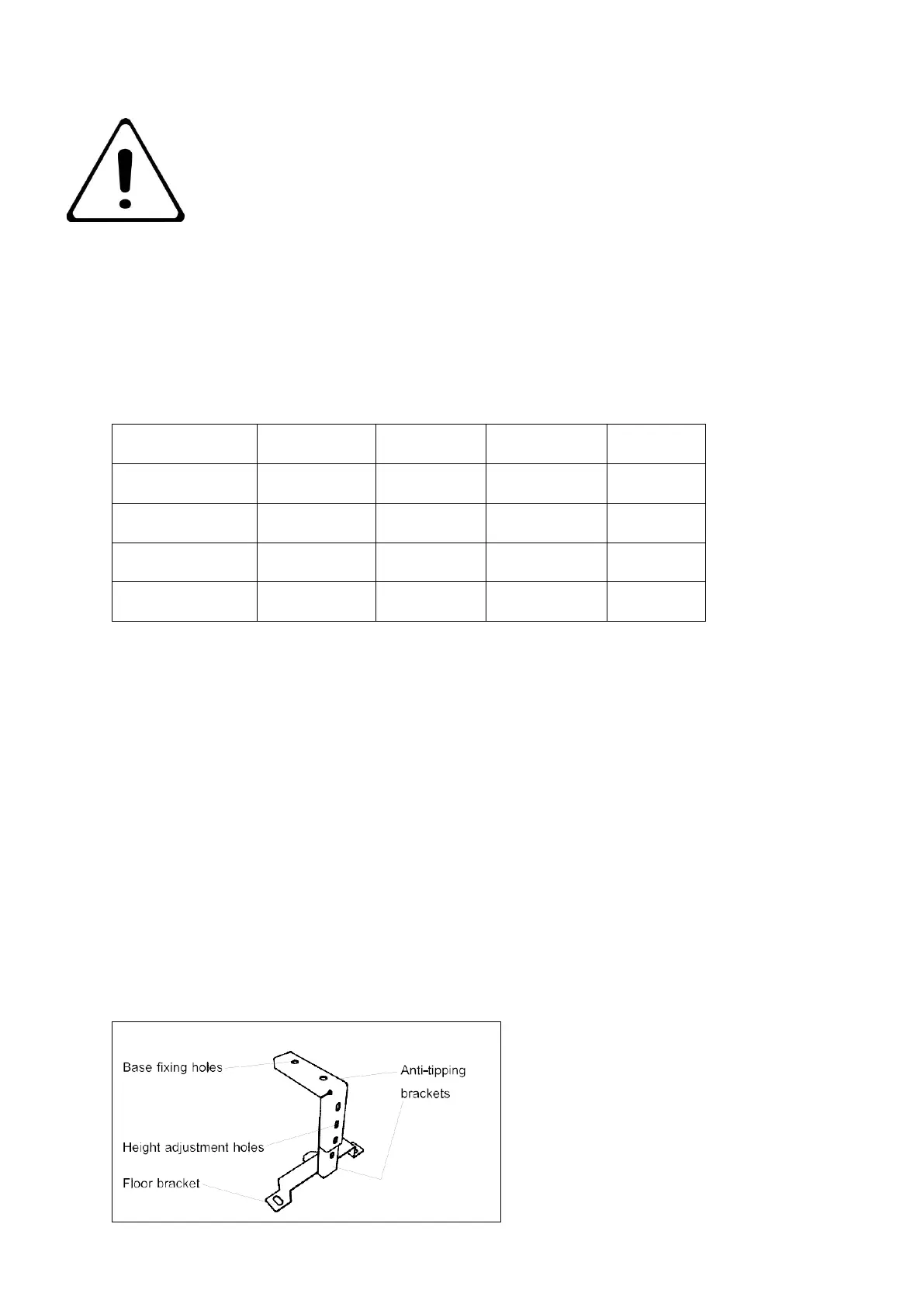

Anti-tipping Kit

An anti-tipping mechanism is supplied with unit. If these are to be fitted, the brackets must be fitted

to locate the fryer in the correct position relative to any walls as detailed below. Fixing holes are

provided in the fryer base to accommodate the bracket. The bracket should be fitted

as detailed

in Figure 1. The retaining chain has a quick release eyelet. Secure to fixing point and secure

bracket to floor after alignment with anti-tipping device attached to

the fryer. Adjust to slide below

floor bracket.

Loading...

Loading...