AXLES, TIRES, and TRACKS Liquid Fertilizer Applicator A10 / A13 / A18 / A24 Page 35

AXLES, TIRES, and TRACKS

Setting Axle Width

IMPORTANT: Adjust track axles out of

the shipping width before

transporting or application. Set axles

to the widest setting possible to

match row width. Use only the holes

with measurements. See axle width

charts.

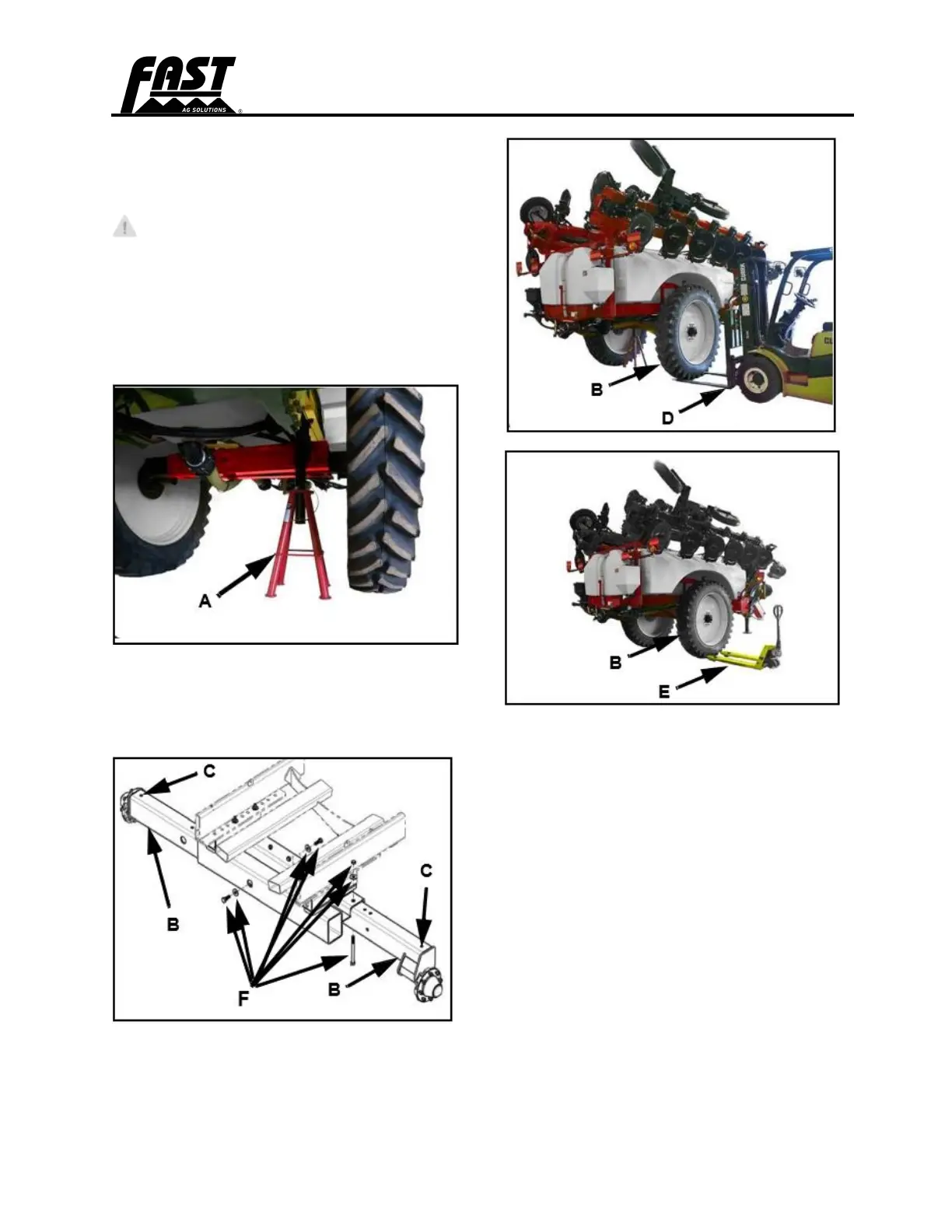

1. Jack one side up on frame in front of

axle and support the frame on the

rear of the axle with jack stands (A).

10-ton jack stand shown.

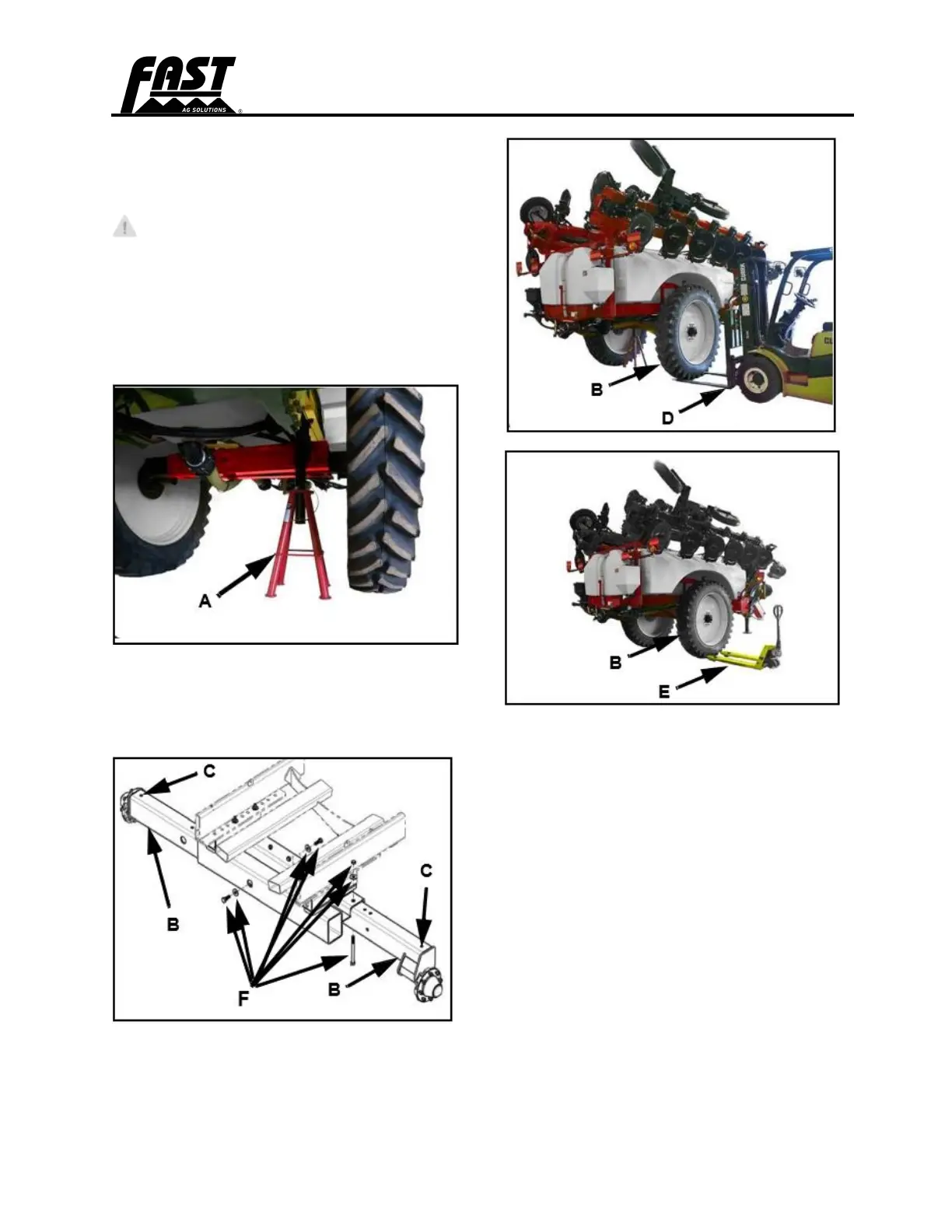

2. Remove the axle bolts (F) and slide

the axles (B) out of shipping holes

(C).

3. Using a forklift (D) or pallet jack (E),

slide the wheel and axle tube (B) out

to the holes matching row width (See

axle width charts). Axles (B) must be

moved out from shipping holes (C) to

match crop spacing, to prevent crop

damage, and for stability. Set both

axles to the same width.

4. Reinstall the axle hardware with the

threads facing up.

5. Torque the 5/8” bolts to 149 N-m (110

ft-lbs.) and the 3/4” bolts to 271 N-m

(200 ft-lbs.).

6. Repeat for the other side.

Loading...

Loading...