AXLES, TIRES, and TRACKS Liquid Fertilizer Applicator A10 / A13 / A18 / A24 Page 44

2. Check for material buildup between mid-wheels and idler wheels. Buildup can damage or

crush guide lugs and can increase chances of derailing the track. If guide lug tip damage

is seen, it may be due to material buildup.

3. Look over mid rollers and idler wheels for visible cracks around the bolt pattern or the rim.

If seen, contact your Fast Ag Solutions dealer for the best recommendation of repair or

replacement.

Track Service

Idler Wheels and Mid-Rollers

Idler Wheel Hub Oil Level

Idler Wheel and Mid-Roller Cap Screws

Mid-Wheel, Wedges, Idler, and Mid-Roller Cap Screws

If the Applicator is operated with loose cap screws, they may become worn and it may be

necessary to replace them.

Re-tighten track cap screws after working 3 HOURS, 10 HOURS and DAILY during the first week

of operation.

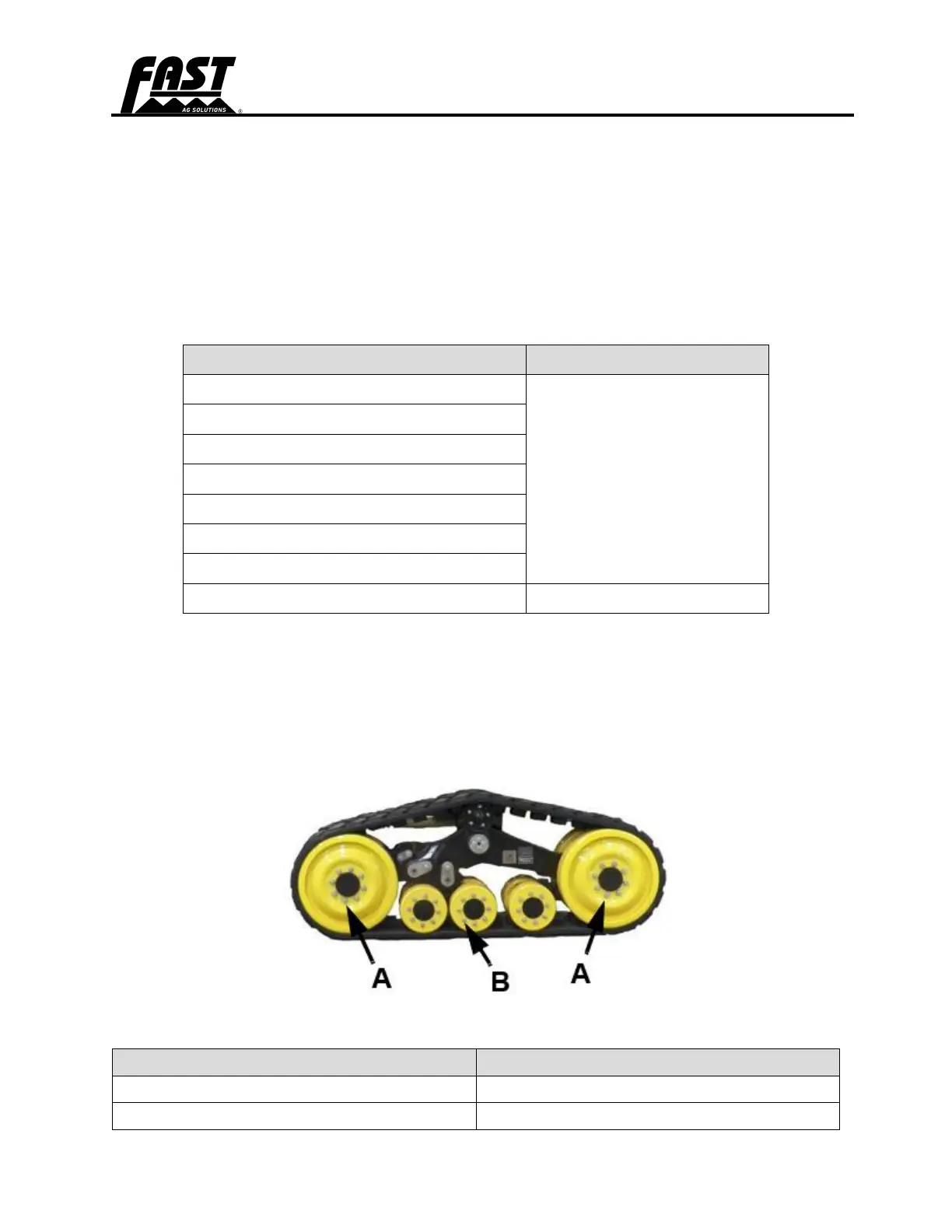

Inspect and re-torque idler wheel (A) and mid-roller (B).

Loading...

Loading...