TIGHTENING HARDWARE Liquid Fertilizer Applicator A10 / A13 / A18 / A24 Page 74

Figure 16: Common imperial bolt grade markings

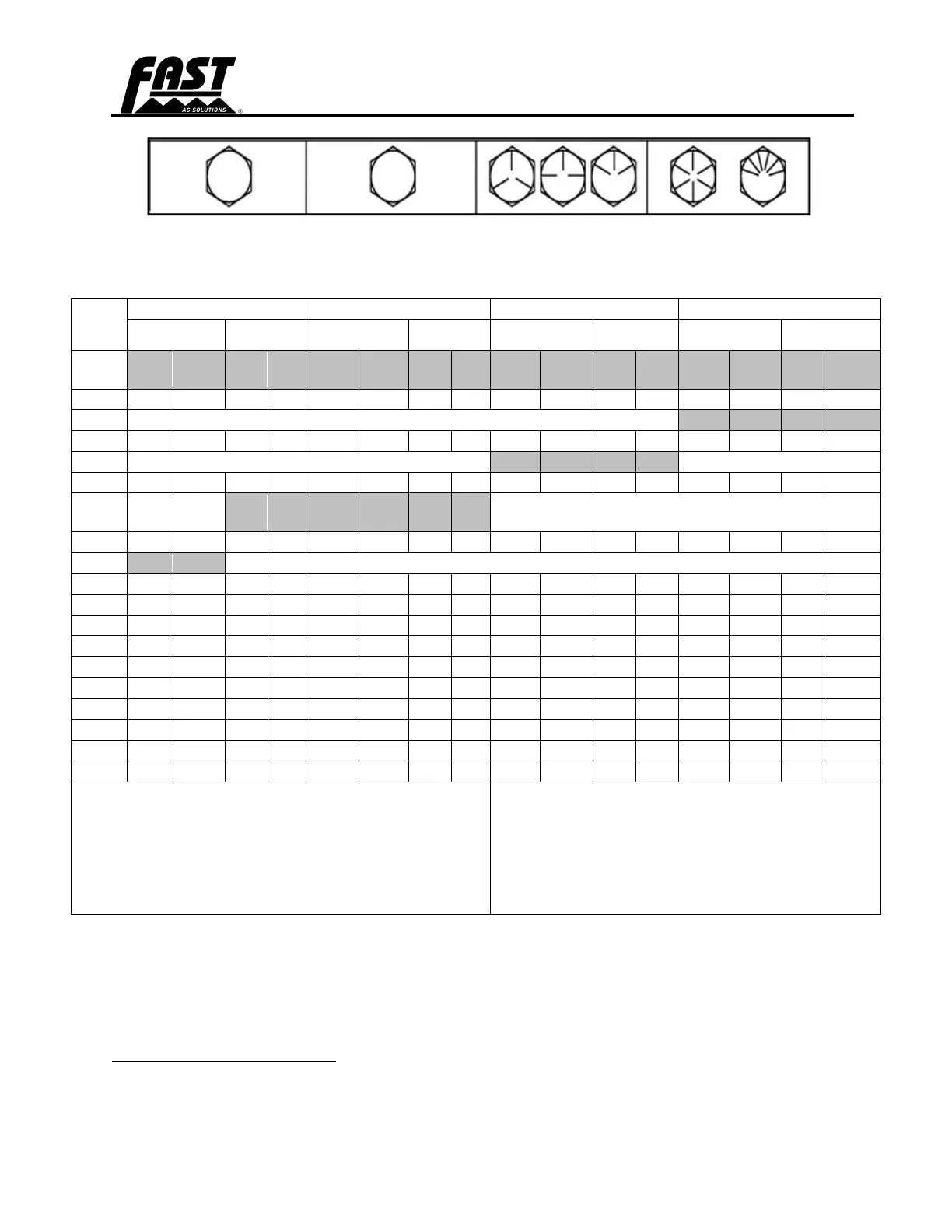

Unified Inch Bolt and Screw Torque Values

Torque values listed are for general use only, based on the

strength of the bolt or screw. DO NOT use these values if a

different torque value or tightening procedure is given for a specific

application. For plastic insert or crimped steel type lock nuts, for

stainless steel fasteners, or for nuts on U-bolts, see the tightening

instructions for the specific application.

Shear bolts are designed to fail under predetermined loads.

Always replace shear bolts with identical grade.

Replace fasteners with the same or higher grade. If higher

grade fasteners are used, tighten these to the strength of the

original. Make sure fastener threads are clean and that you

properly start thread engagement. When possible, lubricate

plain or zinc plated fasteners other than lock nuts, wheel bolts,

or wheel nuts, unless different instructions are given for the

specific application.

Grade 2 applies for hex cap screws (not hex bolts) up to 6 in. (152 mm) long. Grade 1 applies for hex cap

screws over 6 in. (152 mm) long, and for all other types of bolts and screws of any length.

“Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings,

or 7/8 in. and larger fasteners with JDM F13C, F13F or F13J zinc flake coating.

“Dry” means plain or zinc plated without any lubrication, or 1/4 to 3/4 in. fasteners with JDM F13B, F13E

or F13H zinc flake coating.

Loading...

Loading...