AXLES, TIRES, and TRACKS Liquid Fertilizer Applicator A10 / A13 / A18 / A24 Page 45

Check Track Alignment

1. Prior to checking track alignment, the implement should be empty and spring tensioning

mechanism set properly with no pre-load.

2. Pull the implement on a flat surface for a suitable timeframe allowing the belts to relax and

move freely on the undercarriage rollers.

3. Drive in a straight line for roughly 200 ft and coast the tractor to a stop. Place the tractor

in PARK and apply the emergency brake. Do not apply braking action during this process

as sudden stops can affect track position during the alignment process.

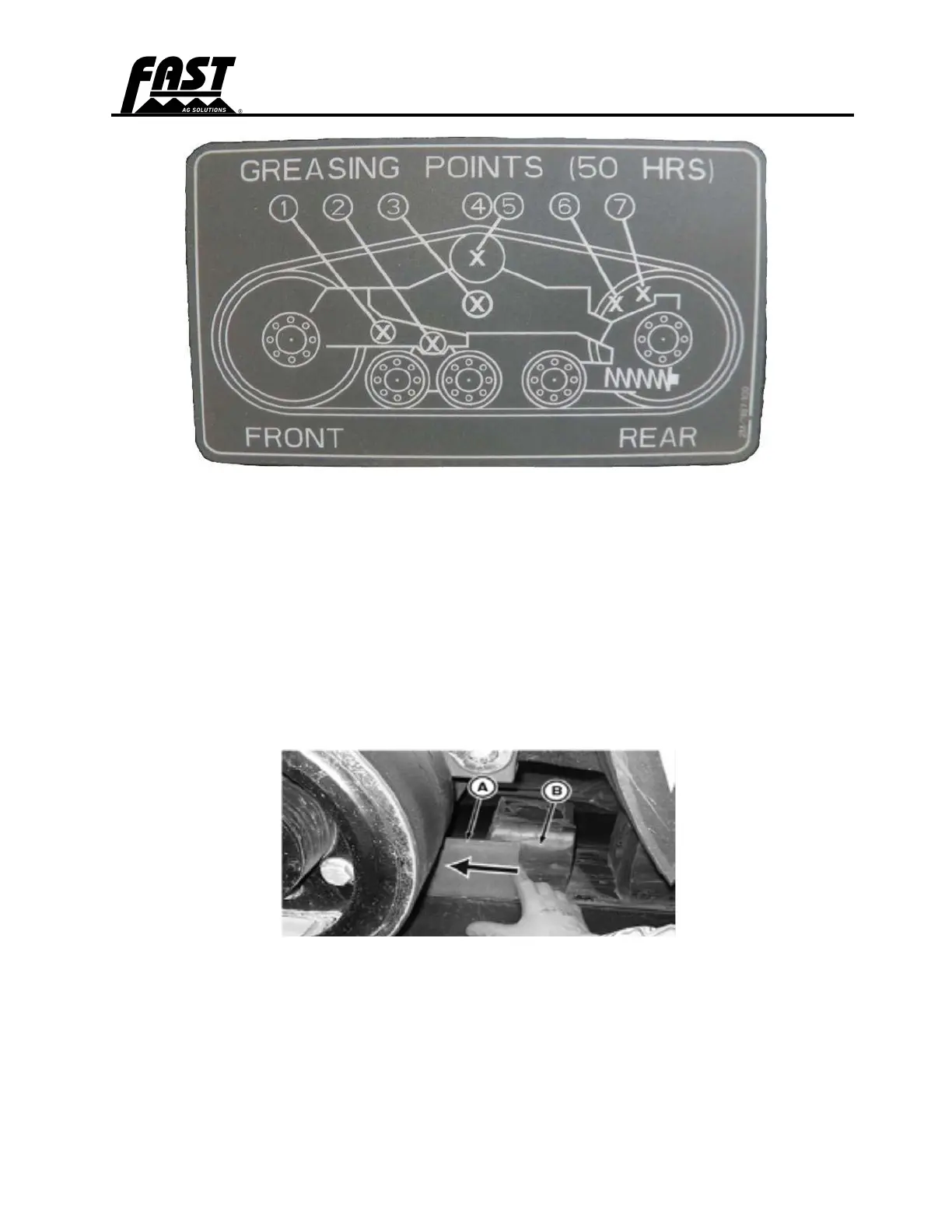

4. Using a ¼” x 4” x 8” shim (A) slid between the front mid-roller and guide lugs (B). Bridge

guide lugs with the shim maintaining pressure on a minimum of 2 lugs.

5. If the shim fits freely between the lugs and mid-roller on both sides of the undercarriage,

the alignment is correct. It the shim binds and does not fit between the mid-rollers / guide

lugs, track adjustment is necessary.

Loading...

Loading...