35

AD 951

212UBB

"!

&

#

$%

"

!

Planer-Thicknesser

A 941 / AD 941 / AD 951

The digital indicators may lose their calibration

during transport. To set the indicator precisely,

open the clamping screw and remove from the

handwheel. Turn it until the mea-sured value of

a previously processed workpiece is precisely

displayed.

Reinsert the indicator into the handwheel and

carefully tighten the clamping screw.

!Digital clock

"Clamping screw

Digi-Drive or Power-Drive:

Procedure: see the following pages

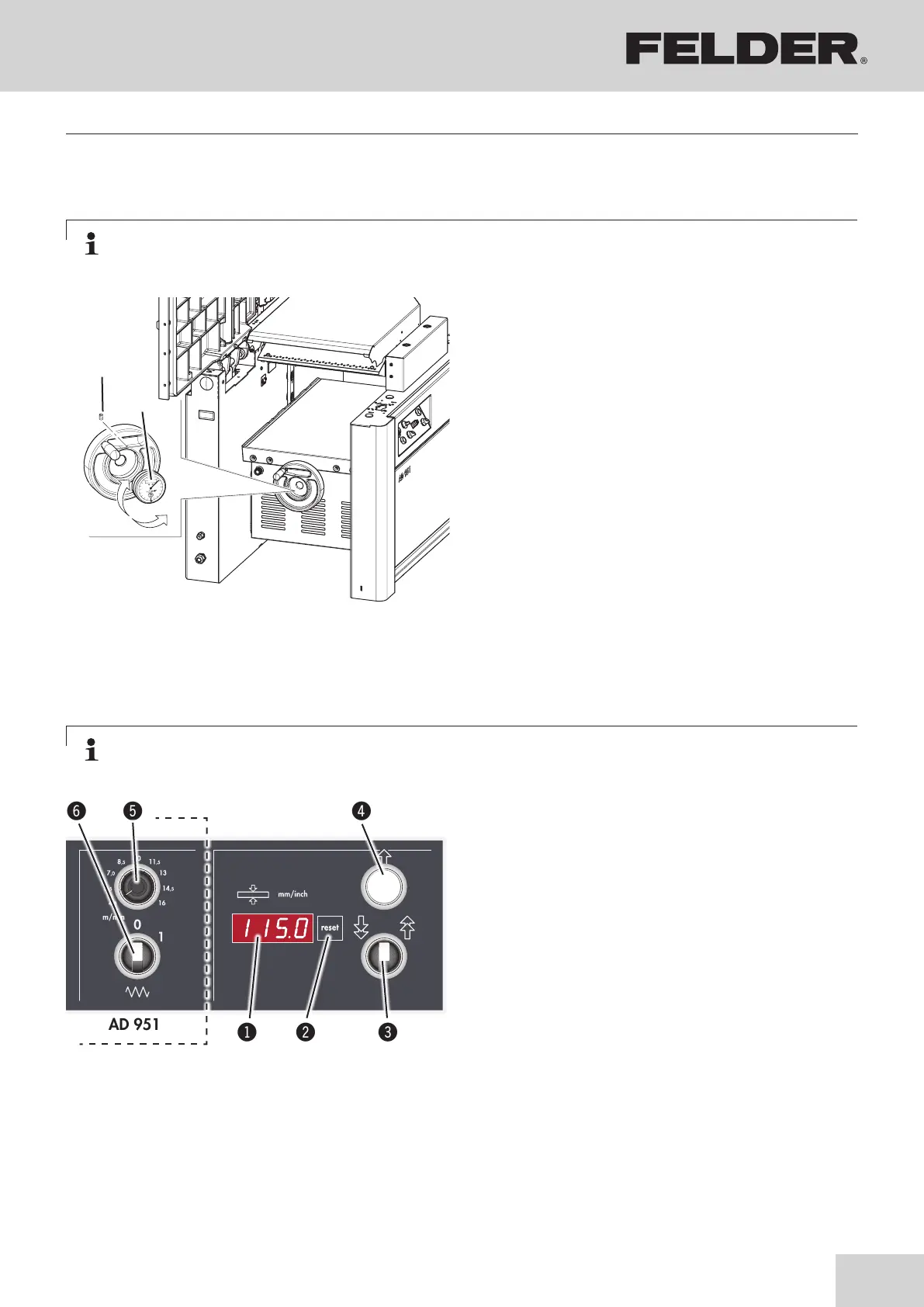

Fig. 8-8: Standard equipment (with the handwheel)

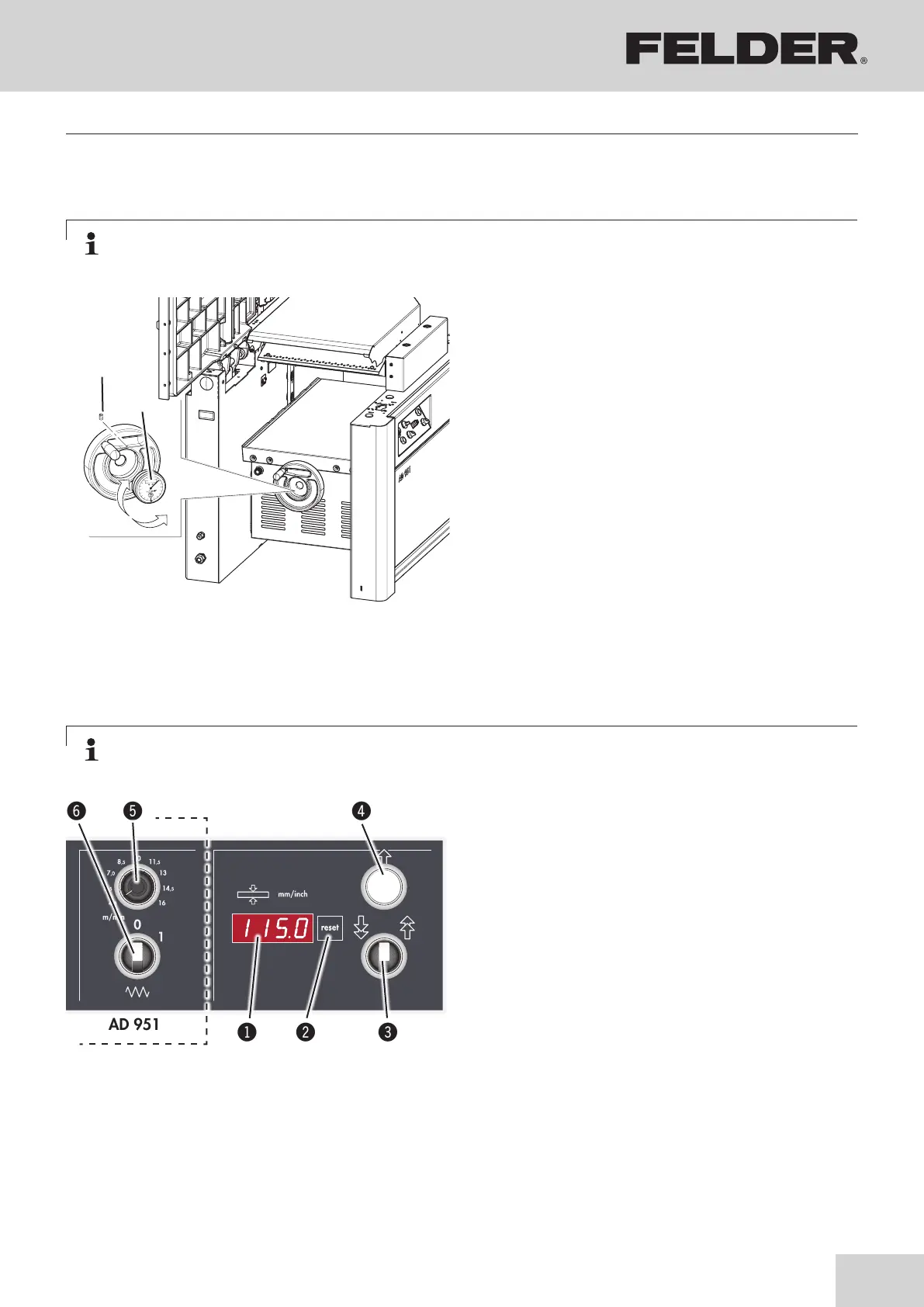

Set the thicknesser height:

• Setting the planer table height using key in steps of

0,1 mm / 0,005 “.

• To move, use the quick motion use switch.

Calibration of control unit:

• Move the thicknesser table to 20 mm/0,790 “

position (using a test piece).

• Press Reset key for 10 seconds.

Conversion mm/inch

• Press Reset key while switching on the machine

(main switch).

!Actual value display

"Reset button

#Quick motion switch

$Set the thicknesser height

%Potentiometer

&ON/OFF feeder switch

8.7 Height adjustment of the thicknesser table with the handwheel

Note:

To compensate for the thread clearance, adjust the thicknessing table from bottom to top.

Note:

To compensate for the thread clearance, adjust the thicknessing table from bottom to top.

8.8 “Power-Drive” equipment

Fig. 8-9: Power-Drive

Making adjustments and preparations

Loading...

Loading...