39

212UAB

! "

Planer-Thicknesser

A 941 / AD 941 / AD 951

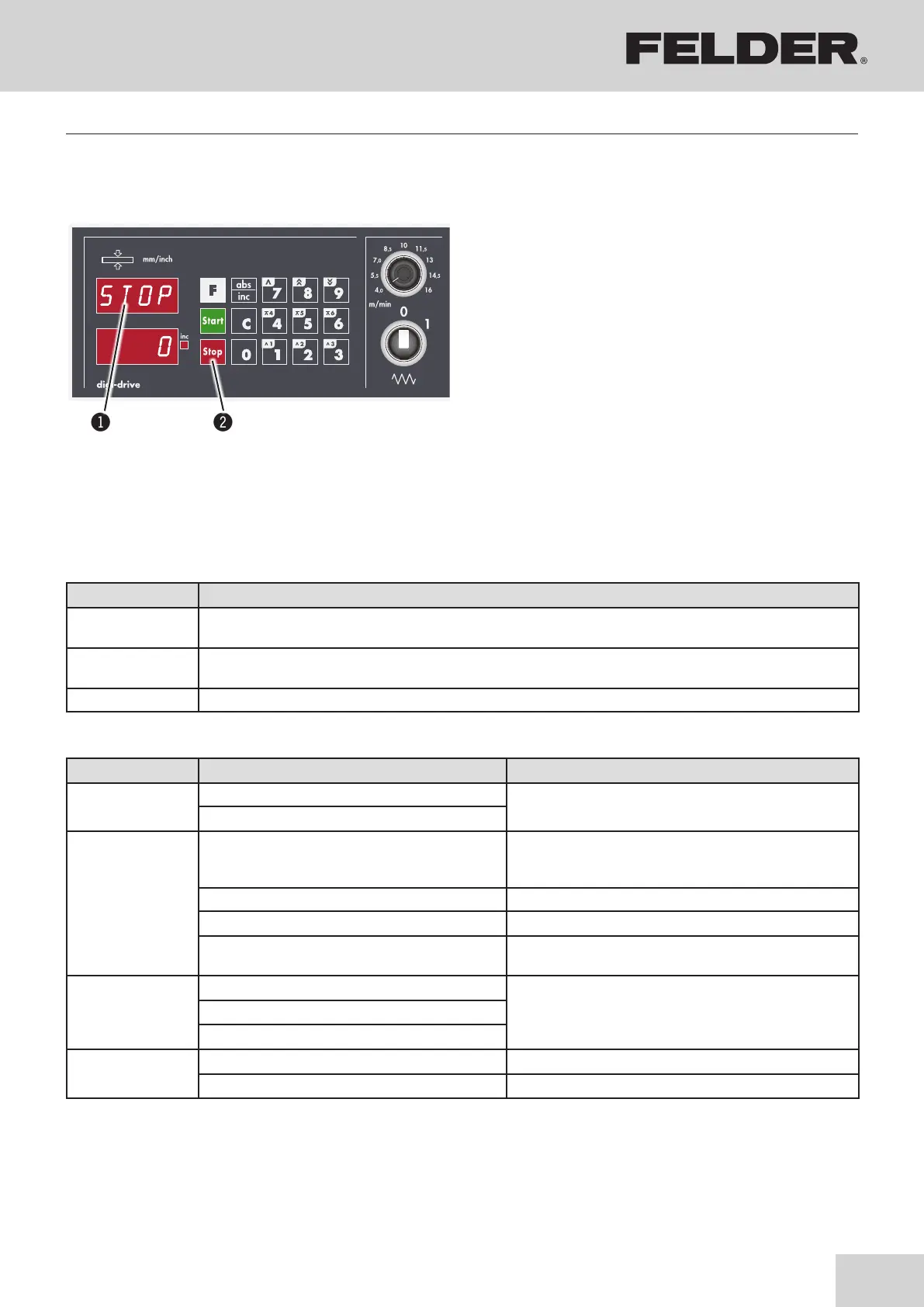

Fig. 8-15: Error messages

8.9.8 Error messages

If an error occurs, the error number or alternatively the

error text is displayed in the actual value display.

Error codes are deleted by pressing the Stop key.

!Actual value display

"Stop key

Making adjustments and preparations

Error codes Cause Solution

ENCO The direction of rotation is connected incorrectly

Please contact customer service.

Measuring system error

CURR

Axle drive is overloaded

(Collision with the workpiece)

Remove blockage

1. Thicknesser table: place to the bottom

2. Remove workpiece

Axis not calibrated (block) Calibration of control unit

Motor defect Please contact customer service.

Soiled mechanics (Thicknesser table height

spindles and chain drive)

Cleaning, Lubrication

See chapter entitled >Service<

SHOR

Cable scrimped

Please contact customer service.Motor defect

Error in electrical system

STOP

Emergency stop actuated Unlock the emergency stop switch

Extraction hood open Close dust extraction hood correctly (Thickness planing)

Note: Press the Stop key to delete error messages.

Status messages Description

–

END Upper limit switch

Thickness planing - The mechanical end position has been reached

_END Lower limit switch

Thickness planing - The mechanical end position has been reached

–

–

END Height limit switch triggered (Thickness planing)

8.9.9 Error messages - Cause and problem elimination

Loading...

Loading...