48

#

$

!

"

%

Planer-Thicknesser

A 941 / AD 941 / AD 951

1. Before beginning any maintenance work on the

machine, switch it off and secure it against acciden-

tally being switched on again.

2. If required, retool from surface planing to thickness

planing.

3. Extraction system must be connected.

4. Every time the machine is put into operation, test the

kickback guards to ensure that they are functioning

properly.

5. Adjust the thicknessing height.

6. Switch machine on.

AD 941

Raise or lower the gear lever:

• Position up: Feed 6 m/min

• Position down: Feed12 m/min.

AD 951

Select the feed speed with the potentiometer.

Start the motor and engage the gearbox with the

button.

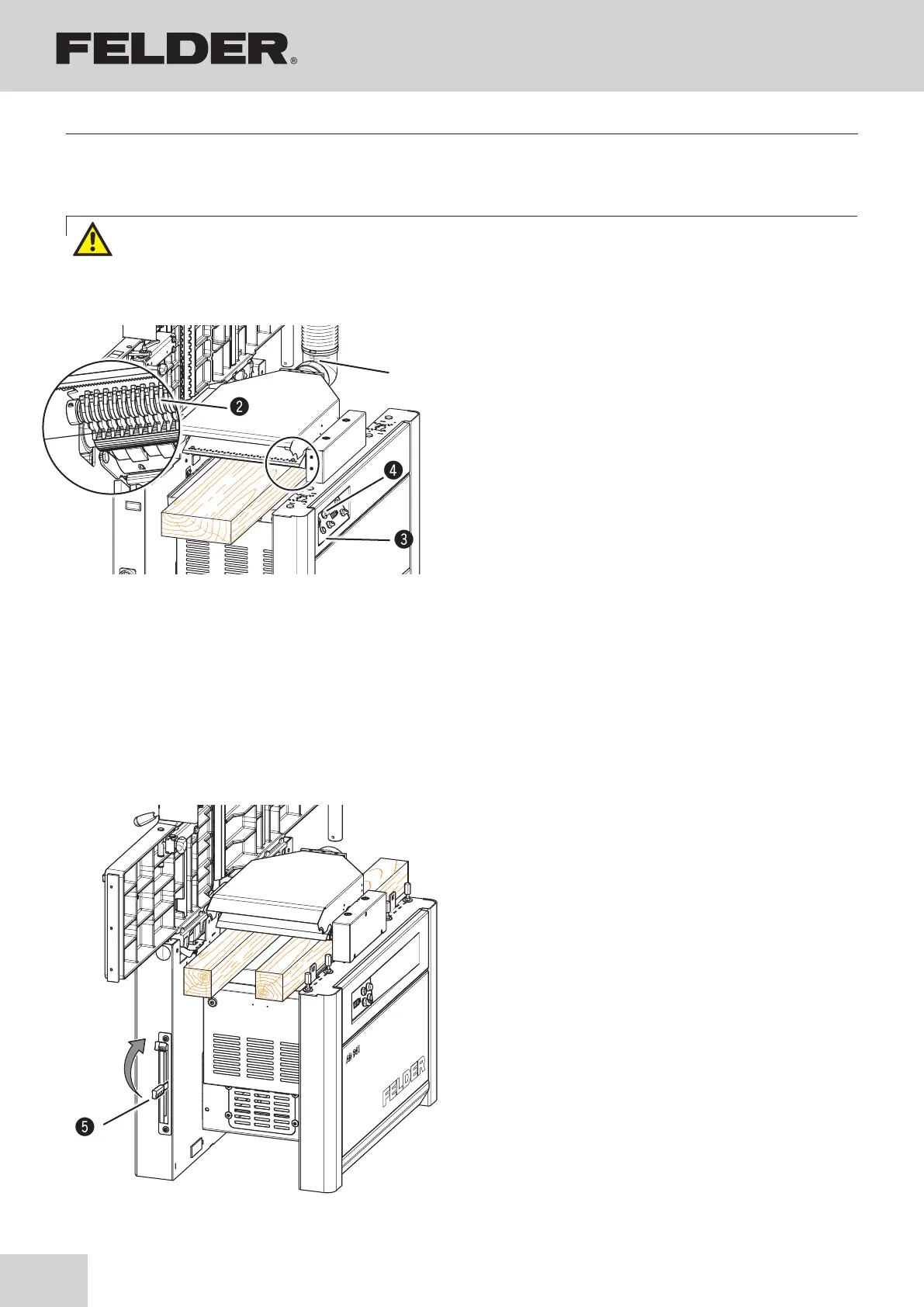

Machining the workpiece:

Place the surface-planed side of the workpiece on

the thicknesser table and push into the machine until

it is drawn in by the feed rollers.

Infeed roller - standard:

A maximum of 2 workpieces can be planed to thickness

simultaneously. These must be pushed in at each end of

the feed roller.

Maximum offset from workpiece to workpiece 1 mm.

Infeed roller - rubber or segmented:

Several workpieces with differing thicknesses can be

machined.

The maximum difference between workpiece to

workpiece measures 1 mm.

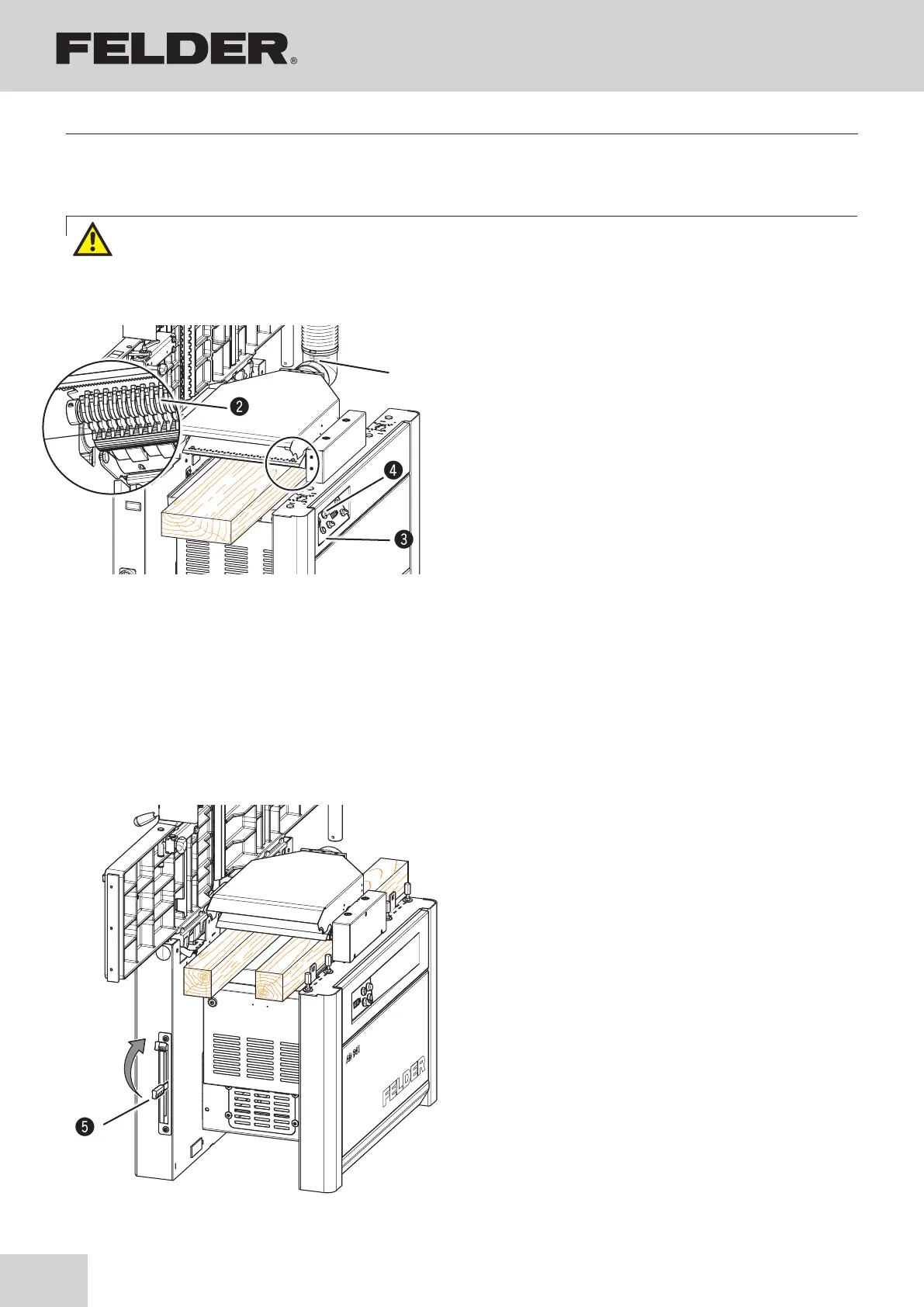

Fig. 9-10: Thickness planing

Fig. 9-9: Thickness planing

!Vacuum hose

"Kickback guards

#ON/OFF feeder switch

$Potentiometer

%Gear lever (AD 941)

9.5.2 Thickness planing

Operation

Warning! Risk of injury through accidental contact with the rota-ting cutterblock

Never reach into the infeed or outfeed side while the machine is running (during machining or idling)!

Loading...

Loading...