TWINFLEX

®

pro² Control Panel Engineering and Commissioning Manual

75

Cable Continuity & Insulation Test Results

After installation of the cable, and termination into all the relevant back-boxes, install a wire link

between the zone +ve and –ve connections at the last device in order to be able to take cable continuity

readings, removing it to take insulation readings. Make sure that all the cables are dressed smoothly

and neatly into their back-boxes in order that they will not be disturbed after the readings are taken.

The commissioning engineer will require these readings, along with correctly marked ‘as-wired’

drawings, before attending site to commission the system.

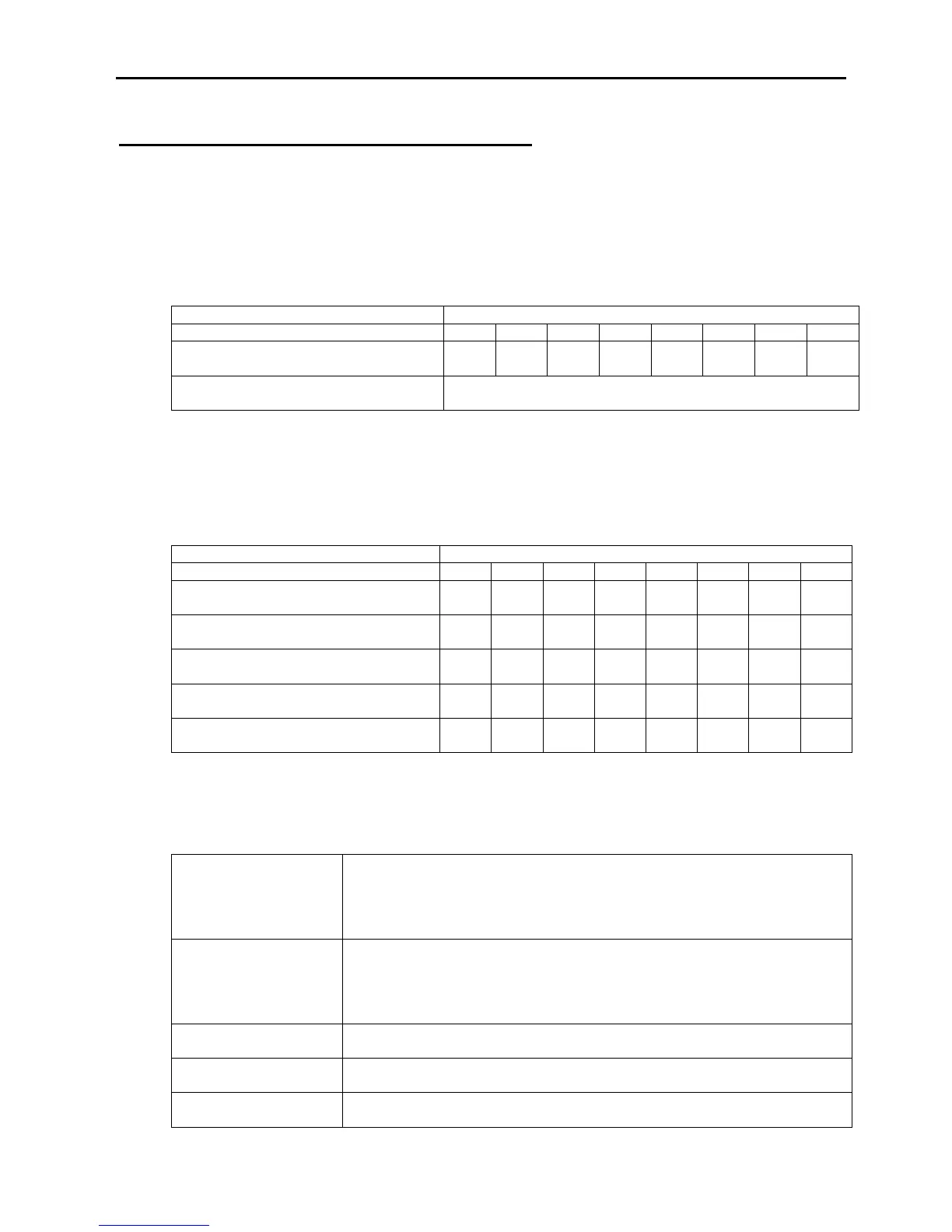

Continuity Reading (ohms)

Zone +ve to –ve with a temporary link

at the last device.

A reading of approximately 1 ohm per 100 metres of 1.5 mm

2

cable is expected and any significant

variation from this should be investigated. If the above readings are satisfactorily showing circuit

continuity then you may also take the reading below, remembering to remove your temporary link at the

last device.

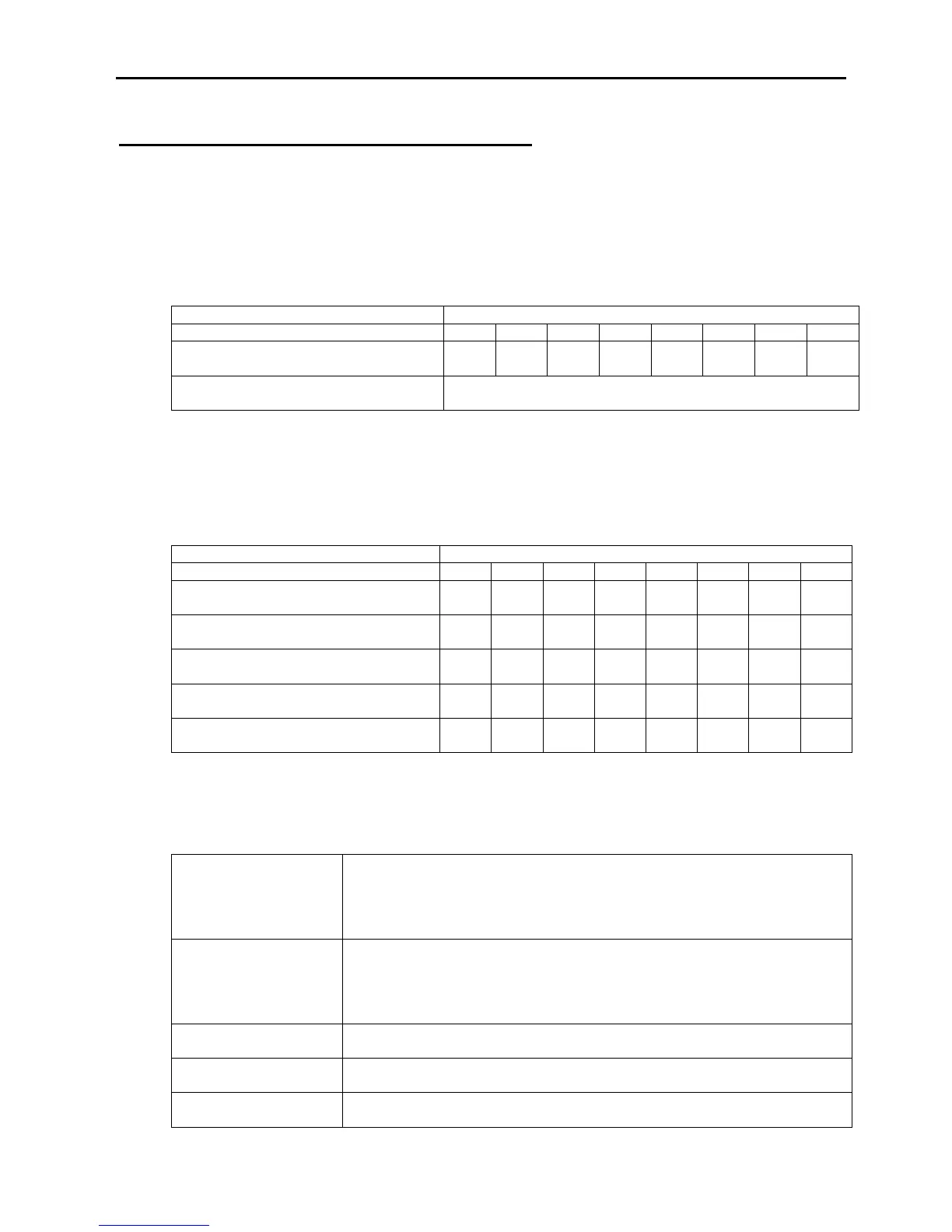

Insulation Reading ( M ohms)

Screen to mains Earth: with scrn

disconnected from panel

A reading in excess of 1M ohm is expected and any significant variation from this should be

investigated. If the readings are satisfactory then the zone wiring is largely proven other than for faults

such as complete polarity reversal.

www.acornfiresecurity.com

www.acornfiresecurity.com

Loading...

Loading...