surface looks hazy at the measurement spot. The fact that haze can be seen means that there is scat-

tered light. (A perfectly smooth surface will scatter no light, and thus the measured spot will not be

visible.) Usually roughness less than 2.5 nm will not be visible, while roughness greater than about

25 nm will be extremely hazy.

FILMeasure assumes a Gaussian distribution of the surface height irregularities about the mean and

it assumes that the roughness is small compared to the wavelength. FILMeasure reports the rms

roughness value.

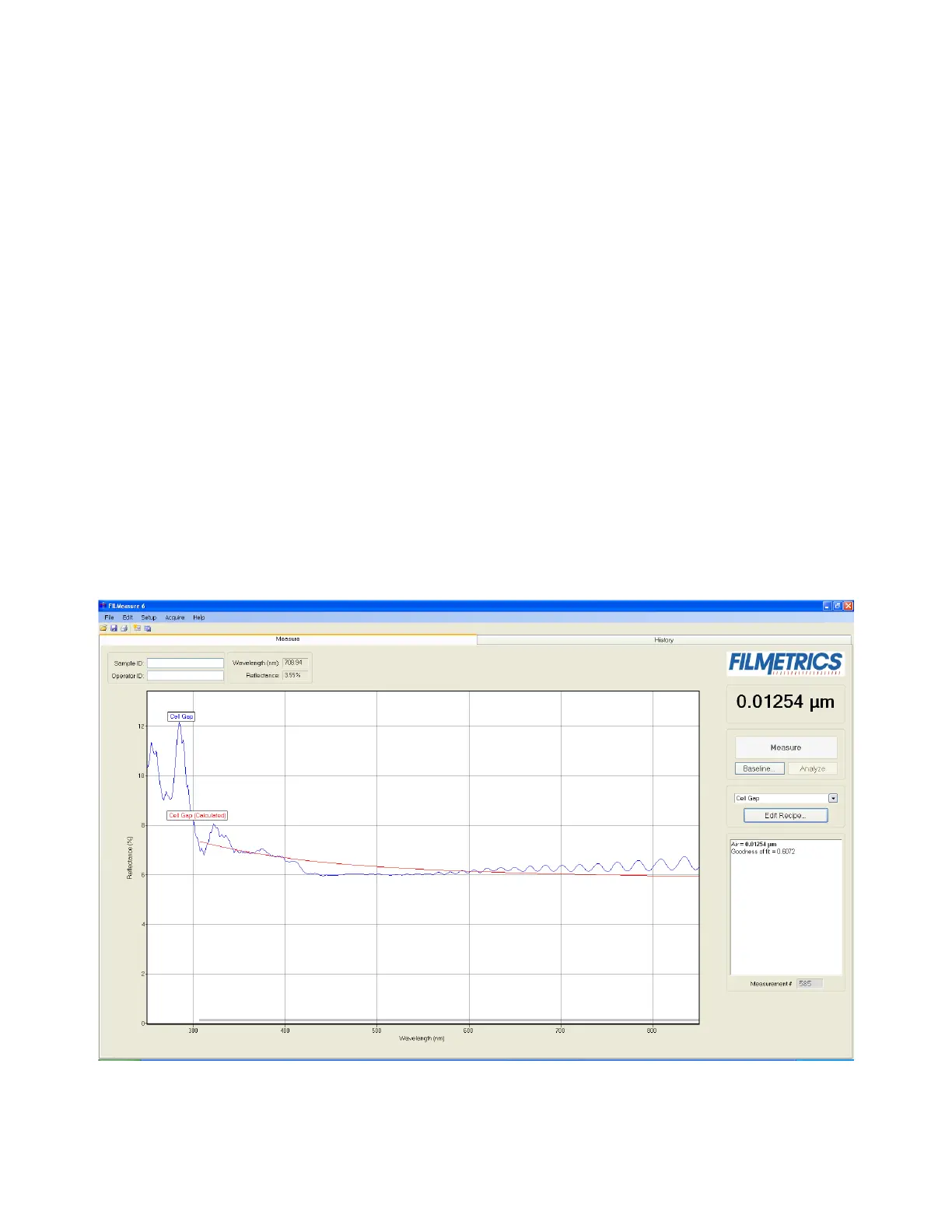

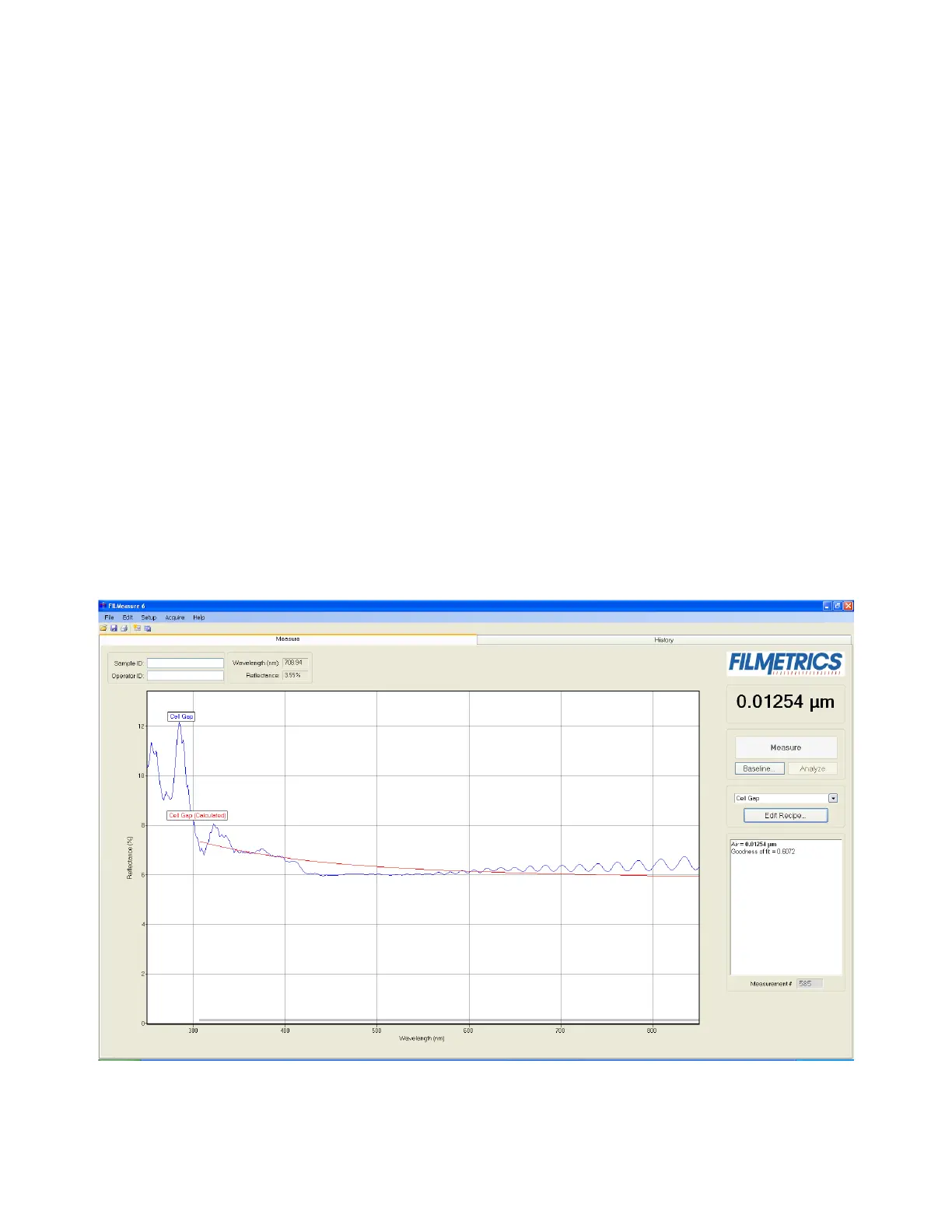

Restricting the wavelength range of the analyzed reflectance spectrum

Occasionally the spectrum from measured films is adversely affected by factors such as absorbing

dyes, birefringence, or non-uniformity – all of which are difficult to model properly. It is often still

possible to make accurate thickness measurements of these films by analyzing only unaffected por-

tions of the spectra. The portion of the spectrum that is used to calculate film properties is deter-

mined by the graphic display or by Edit Recipe>Analysis Options. An example of the difference

is shown below.

Another faster method of controlling wavelength analysis range is with the gray bar at the bottom

of the graph. Drag either end of the bar to a new position on the x-axis to change the analyzed

range without altering the graph dimensions or editing the recipe.

Example of a non-ideal film (spectrum with no oscillations at lower wavelengths) that requires reduced wave-

length range for accurate measurement.

Loading...

Loading...