Principle of Operation

June 2017

Instruction Manual

D103176X012

55

Appendix A Principle of OperationA‐1‐

DVC2000 Operation

The DVC2000 digital valve controller uses a traditional 4-20 mA input signal and converts it into a pneumatic output

pressure that is delivered to the control valve actuator. Accurate control of the position of the valve is enabled by valve

stem position feedback. The way in which the DVC2000 accomplishes this is through a two-stage positioner design.

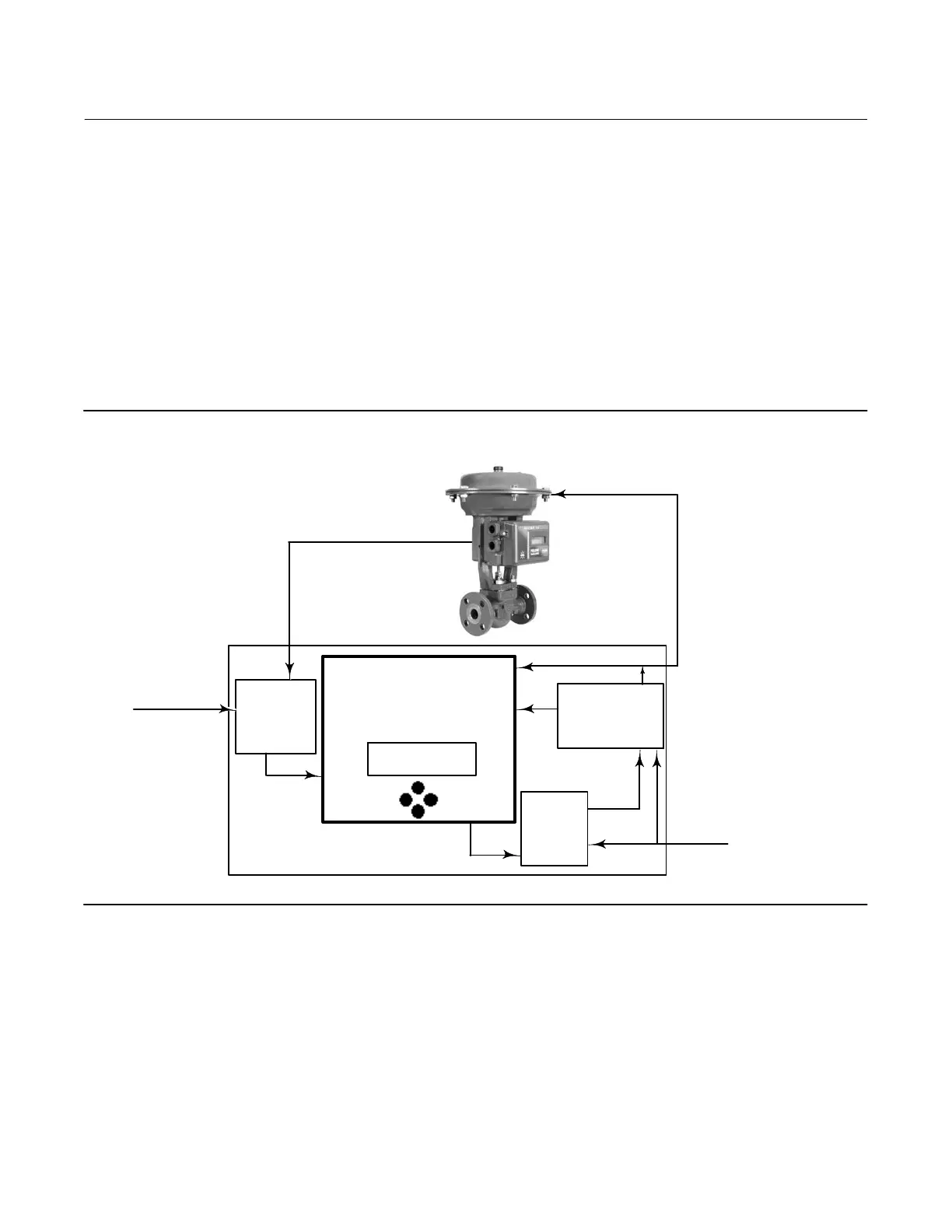

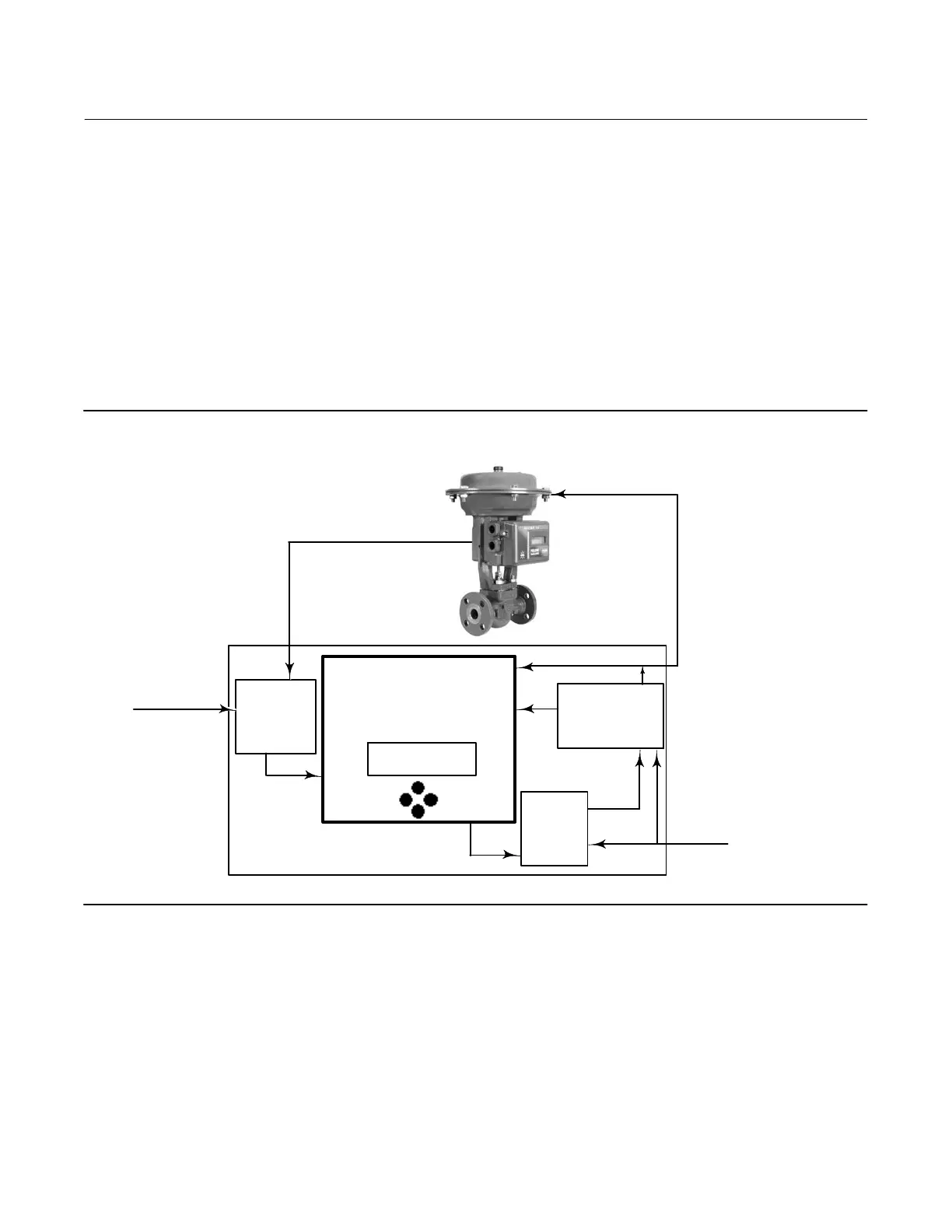

Refer to figure A‐1 for a block diagram of the positioner operation.

Figure A‐1. FIELDVUE DVC2000 Digital Valve Controller Block Diagram

INPUT SIGNAL

(4-20 MA, 9 VOLTS)

TERMINATIONS

&

POSITION

SENSOR

BOARD

MAIN BOARD

ASSEMBLY

ACTUATOR

PRESSURE

SENSOR

TRAVEL = 66.8%

14.6 MA 0.29 BAR

MINOR LOOP

FEEDBACK

DRIVE

SIGNAL

I/P

CONVERTER

(PRE-

AMPLIFIER

AIR SUPPLY

OUTPUT

SINGLE ACTING

RELAY

(POWER

AMPLIFIER)

I/P

PRESSURE

SIGNAL

NON-CONTACT

POSITION FEEDBACK

A traditional 4-20 mA signal provides the set point and power to the instrument. At the same time, the HART protocol

provides instrument and process data through digital communications. The instrument receives this set point and

positions the valve where it needs to be.

D The input signal provides electrical power and the set point simultaneously. It is routed into the terminal board

through a twisted pair of wires. The terminal board contains the termination points for the loop signal (+11/-12). If

the options board is installed, an additional options board set includes additional terminals for the transmitter

output (+31/-32), switch #1 output (+41/-42), and switch #2 output (+51/-52).

D The input signal is then directed to the main electronics board assembly where the microprocessor runs a digital

control algorithm resulting in a drive signal to the I/P converter.

Loading...

Loading...