50Fläkt Woods 8666 GB 2010.06

Specifications are subject to alteration without notice

Installation and maintenance instructions

Control equipment

Alarm guide

When the red LED on the handheld terminal starts to ash

an alarm has been generated. To check the alarm, press the

alarm button (4) once. Detailed information is displayed.

To reset the alarm press the button again and reset it by

changing Conrm/Reset to Active. If the LED lights con-

tinuously an alarm persists. Read the alarm guide para-

graph above for more information.

General fault-tracing

1. Read off the alarm from the handheld terminal.

2. Check the connections on terminal blocks and

quick connectors.

3. Check the component from which the alarm

was generated.

4. Check the connection of the component.

5. Check the contact function on the digital alarms in the

controller, compare with the drawing and component.

6. Check the parameter settings.

Below is a list of possible error messages and proposed

corrective action/causes.

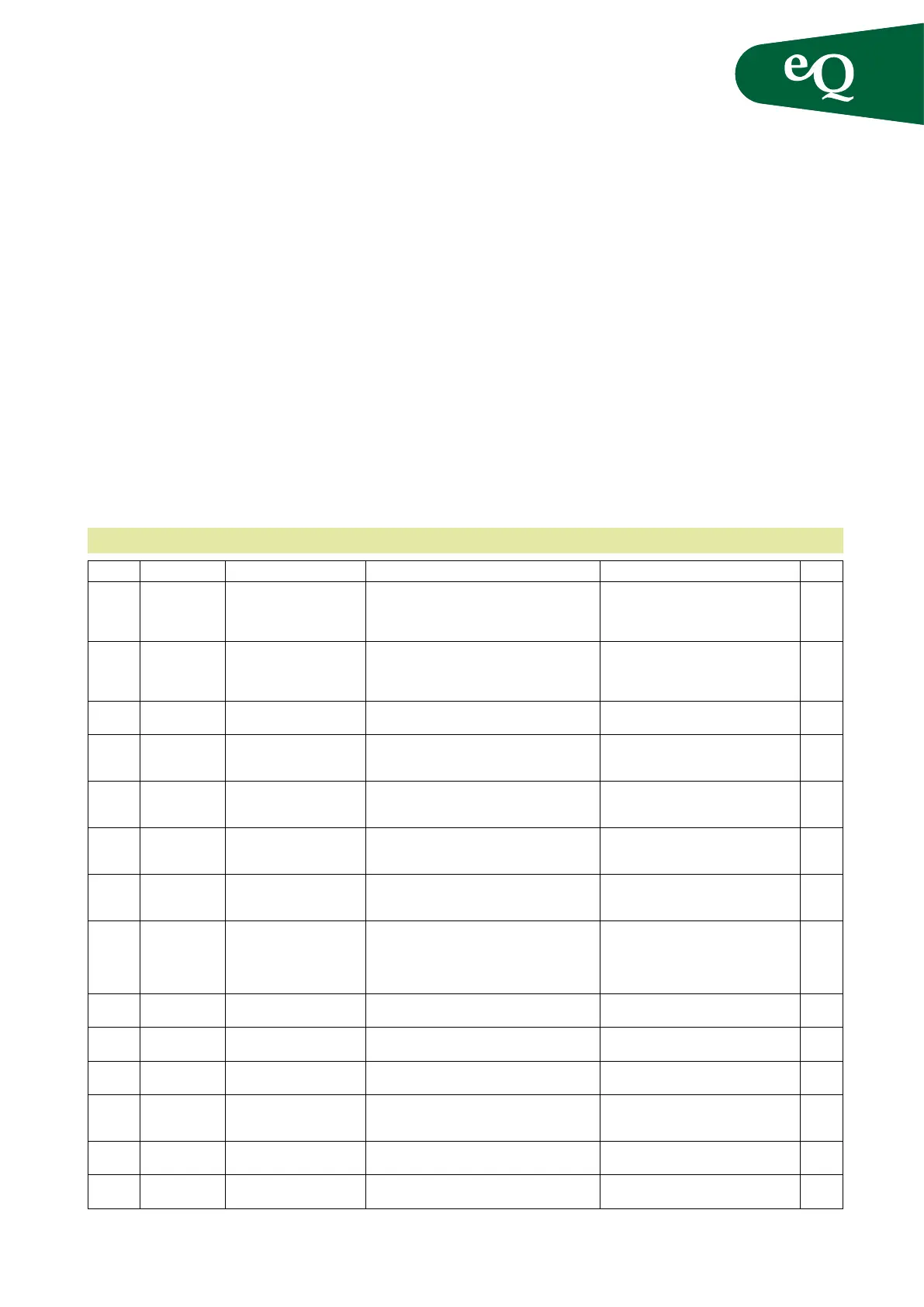

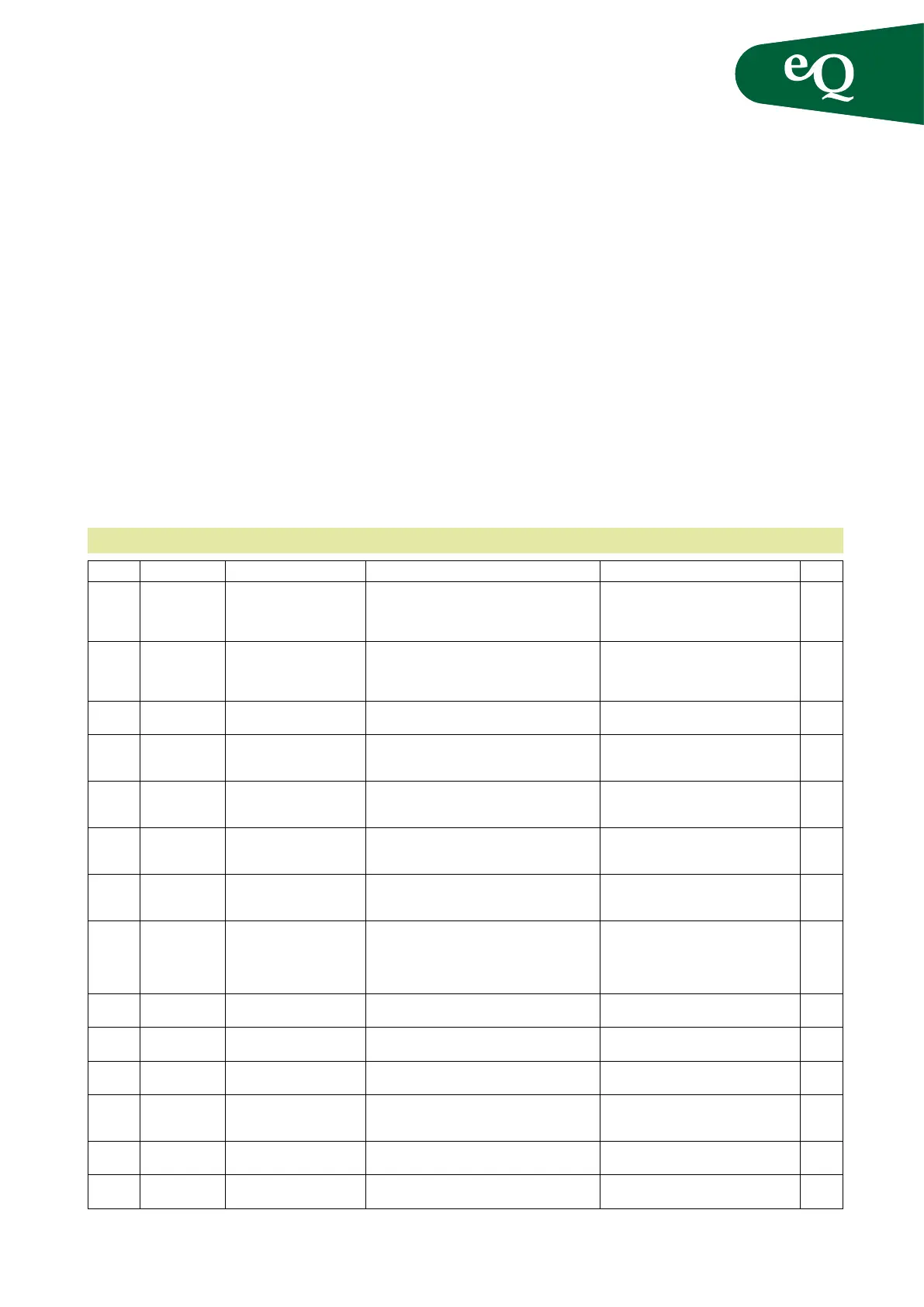

Alarm Alarm text Cause Action – Operation Action – Startup Type

Fire

alarm

Fire alarm:

Alarm

The Fire terminal block in

the control panel indicates

an alarm

Check the connected re control centre on the air

handling unit.

Is re extinguishing equipment connected

to the control plate? If not check the jump-

er on the “Fire” terminal block. Check the

contact function for the “Fire” input.

A

Pump/

Alarm

heating/

cooling

Alarm pump

heating: Alarm

Motor protection alarm

pump heating water

Check the pump motor protection. Check the contact function on the Alarm

CP1/GT7 terminal block. Check that the

motor circuit breaker is on.

B

Alarm electric

heating: Alarm

Integrated electric heater

alarm signal triggered

Check the electric heater thermal overload

protection.

Check the contact function on the

Alarm CP1/GT7 terminal block.

A

Alarm recovery:

Alarm

The recovery control unit

indicates an alarm.

Check the alarm on the control unit. Reset the

control unit by switching off the power to it. Fault

trace using the heat exchanger instructions.

Check connections. Reset the control unit

by switching off the power to it. Fault

trace using the heat exchanger instructions.

B

Pump recovery

alarm: Alarm

Energy recovery pump mo-

tor protection alarm

Check the pump motor protection. Check the contact function on the “Alarm

HEX” terminal block. Check that the mo-

tor circuit breaker is on.

B

Cooling pump

alarm: Alarm

Cooling pump motor

protection

Check the pump motor protection. Check the contact function on the Alarm

CP2/DX terminal block. Check that the

motor circuit breaker is on.

B

Alarm DX

cooling

Alarm from cooler Check the alarm output on the cooler. Check the contact function on the Alarm

CP2/DX terminal block. Check that the

cooler is not in alarm mode.

Extra

heating/

cooling

pump/

alarm

Alarm pump

Extra heating

Pump alarm Extra heating Check the extra heating/preheater pump motor

protection.

Check the contact function. Check that the

motor circuit breaker is on.

Alarm Extra

electric heating

Alarm Extra electric heating Check the extra electric heater thermal overload

protection.

Check the contact function. Check that the

motor circuit breaker is on.

Alarm Extra

cooling pump

Extra cooling pump alarm Check the extra cooling coil pump motor

protection.

Check the contact function. Check that the

motor circuit breaker is on.

Alarm Extra DX

cooling

Alarm Extra DX cooling Check the alarm output on the cooler. Check the contact function. Check that the

cooler is not in alarm mode.

Filter Filter alarm:

Alarm

Combined lter alarm signal

in SAF and EAF. SAF lter

or EAF lter in alarm.

Check all lters. Check that all lter monitors are set to

nal pressure drop.

B

Alarm Filter clogged in supply

air unit

Check supply air lter. Check that lter monitors are set to nal

pressure drop.

B

Alarm extract

air lter

Filter clogged in extract

air unit

Check the extract air lters. Check that lter monitors are set to nal

pressure drop.

Alarm list

Loading...

Loading...