TemplateA4_v20130506

16

5.5 Component parts, equipment

Type

Température de service mini. / maxi. admissible

Surpression de service admissible

Surpression d`essai

Capacité nominale

N° de série

litres

bar

bar

Type

Typ

Serial-No.

Serien-Nr.

Nominal volume

Nenninhalt

Permissible working overpressure

Zulässiger Betriebsüberdruck

Test overpressure

Prüfüberdruck

Permissible working temperature min. / max.

Zulässige Betriebstemperatur min. / max.

litre

Liter

Flamco STAG GmbH

39307 Genthin

GERMANY

°C

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Année de fabrication

Year of manufacture

Herstellungsjahr

:

:

:

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

2.2

2.3

2

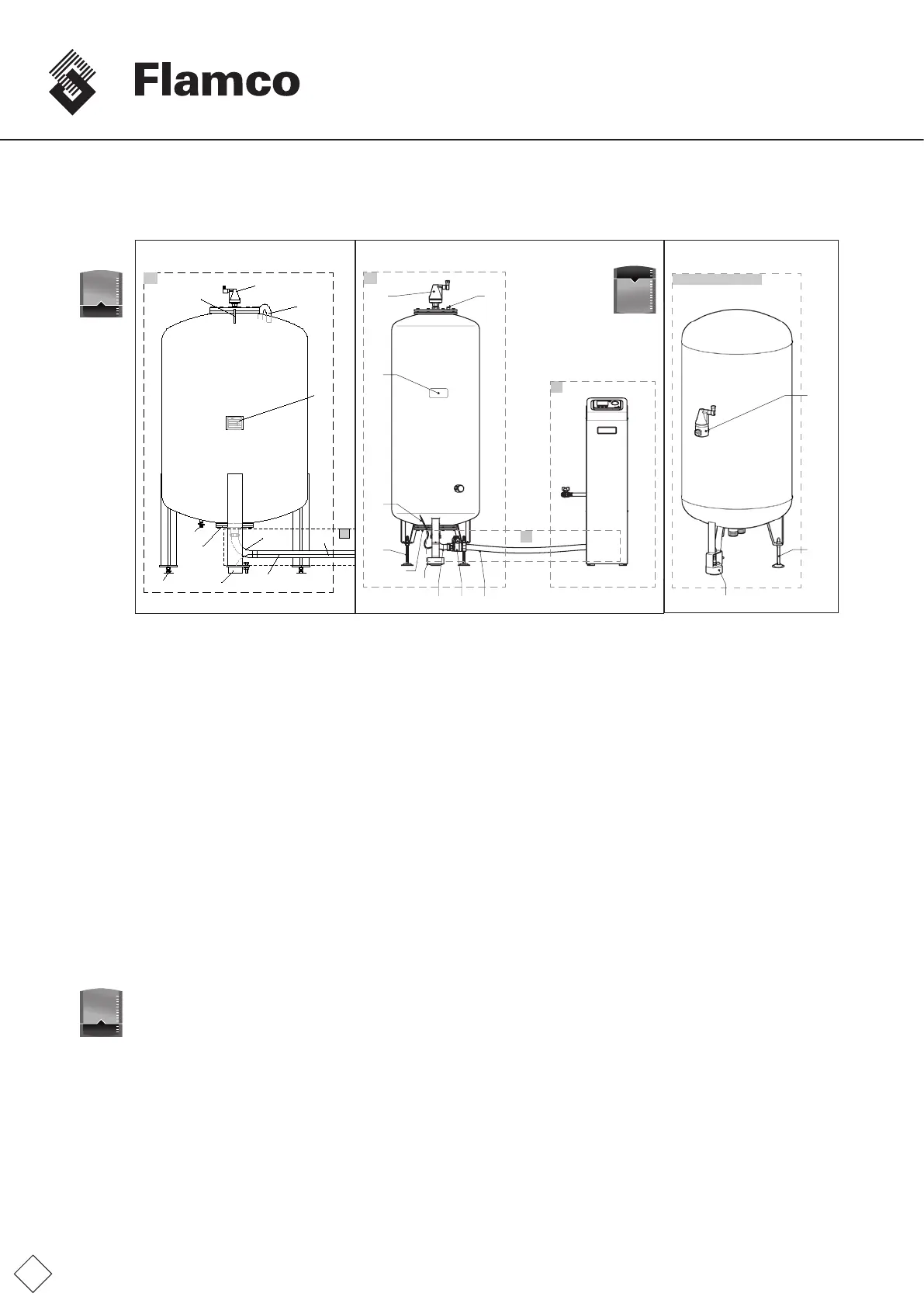

Fig. FM.017.V01.15

1A

1

1.1

3

2

1.5,

1.6

1.10

1.7

2.1

1.8

1.31.2

2.3 2.2

1000 Ltr

≤

1B

1C (Flamcomat starter)

1.2*

1.6

1.7

1 Basic steel vessel (1A/B with built-in,

exchangeable butyl-rubber diaphragm for

absorption of the expansion water under

atmospheric separation conditions).

1.1 Nameplate-Vessel:

1.2 Bleedervalve,oatventwith

air-intakepreventertodissipate

extractedgasesintotheatmosphere

*Incl.Vacuumsafetyvalve

1.3 Atmosphericpressurebalancingconnection

Interiorofvessel(spacebetweeninnervessel

surfaceandouterdiaphragmsurface)

1.5 Flange,vesselconnectionwithinternally

tteddegassingequipment,screw

union,connectionarray

valveoutowlineandpumpsuctionline,

eachwithatgasket(labelling)

1.6 Adjustablefeet.

1.7 Capacitysensorwithscrew-typeround

plugconnectortosignalwire

1.8 Signalwirelevelsensor

1.10 Markingsforpumpandvalveconnection

1.4 Liftinghook,loadsuspensionfortransport

1.9 Lockshieldvalveforcondensatedrainage

2 Connection assembly, pre-installed, including

at seal

2.1 Self-draininglockshieldvalve(vessel)withat

seal,controlunitport

2.2 Flexiblepressure/suctionhose

2.3 Pipebend,atsealing,vesselconnector(DN32:

400 - 1000 liter, DN40: 1200 - 1600 liter.)

3 Pump module, control module, including type

plate

3.1 Pumppressurepipe,systemsupply(marking)

3.2 Pressure sensor

3.3 Pump 1 with manual de-aeration

(hexscrewwithseal)

3.4 Pump 2 with manual de-aeration

(hexscrewwithseal)

3.5 Pump1,wetrunner,self-priming

Aspeedselectswitch,max. position!

BVent(slotted-headscrewwithseal)

3.6 Pump2,wetrunner,self-priming

Aspeedselectswitch,max. position!

BVent(slotted-headscrewwithseal)

3.7 Valvedischargepipe,systemdischarge(marking)

3.8 Particlelter

3.9 Non-returnvalve

3.10 Manualregulatedvalve1(diagram)

3.11 Manualregulatedvalve2(diagram)

3.12 Solenoidvalve,overowvalveno.1

3.13 Solenoidvalve,overowvalveno.2

3.14 Top-upline,incorporatingtheshut-offvalve

(lockshieldvalve),exiblepressurehose,solenoid

valve,top-upvale,no.3,andcheckvalve

(optional)

3.16Safetyvalve(vessel)

3.17Lockshieldvalvesystemconnection(optional)

3.18Automaticdeaeratorwithair-intakepreventer

(MP,DP60-1-50)

3.19 Controlunit,SPCx-lwincludingtypeplate

3.20 Controlunit,SPCx-hwincludingtypeplate

3.21 Bleedpump

3.22 Front panel

3.23 Manualregulatedvalve3(diagram)

1000 Ltr

>

1000 Ltr

>

Loading...

Loading...