TemplateA4_v20130506

22

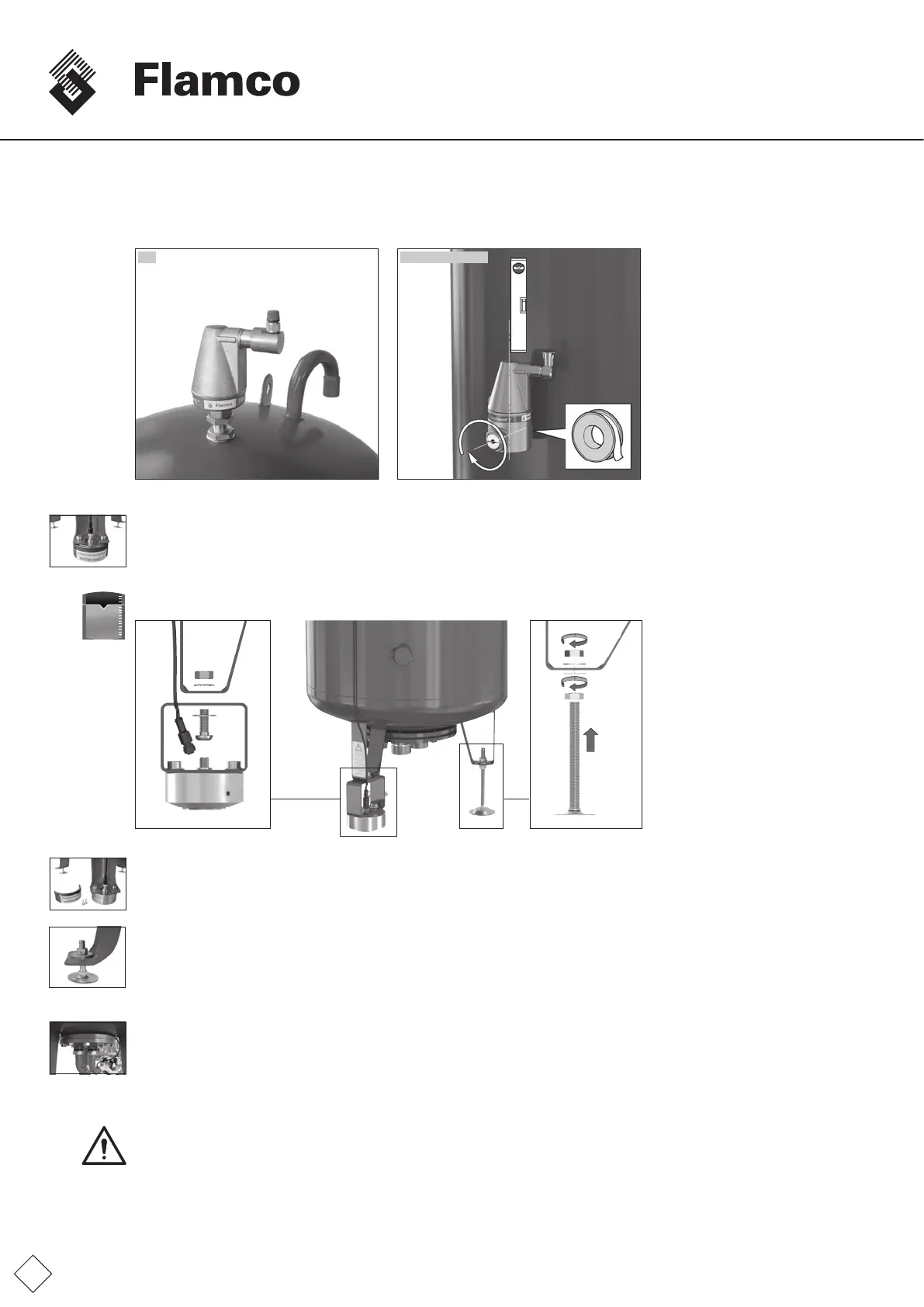

6. Assembly

6.1 Setup

A/B C

(Flamcomat starter)

• Fittheautomaticvent(suppliedseparately).

• Removethetransportsealbythevolumesensoroncethebasicvesselhasbeensetupintheproposedplaceandnofurther

positionalchangesarenecessary.Avoidimpactonthesensorandmakesurethesensorisonasurfacewhichdoesnotimpair

thefunctionofthesensorpressure-pad.

• Installationoftheweight-capacitysensorandtheadjustablefeet.

• Usingthefoot-heightadjuster,adjustthevesseluntilitisvertical.Usetwoverticalmagneticspiritlevels.

• Ensurethatnoexternaladditionalforcescanbeexertedonthebasicvessel(e.g.toolslaidonthevessel,thingsleaningonthe

sides).

• Donotxthebasicvesseltothegroundonwhichitiserected(donotuseanysortoffasteningwhichcanadverselyaffectthe

vessel,e.g.sinkingthefeetintoconcreteorlime,weldingofthevesseloritsfeet,clampsandtiesonthebodyofthestructure

orappurtenances).

• Placethecontrolmodule,thebasicvesselandtheauxiliaryvesselatthesameheight.

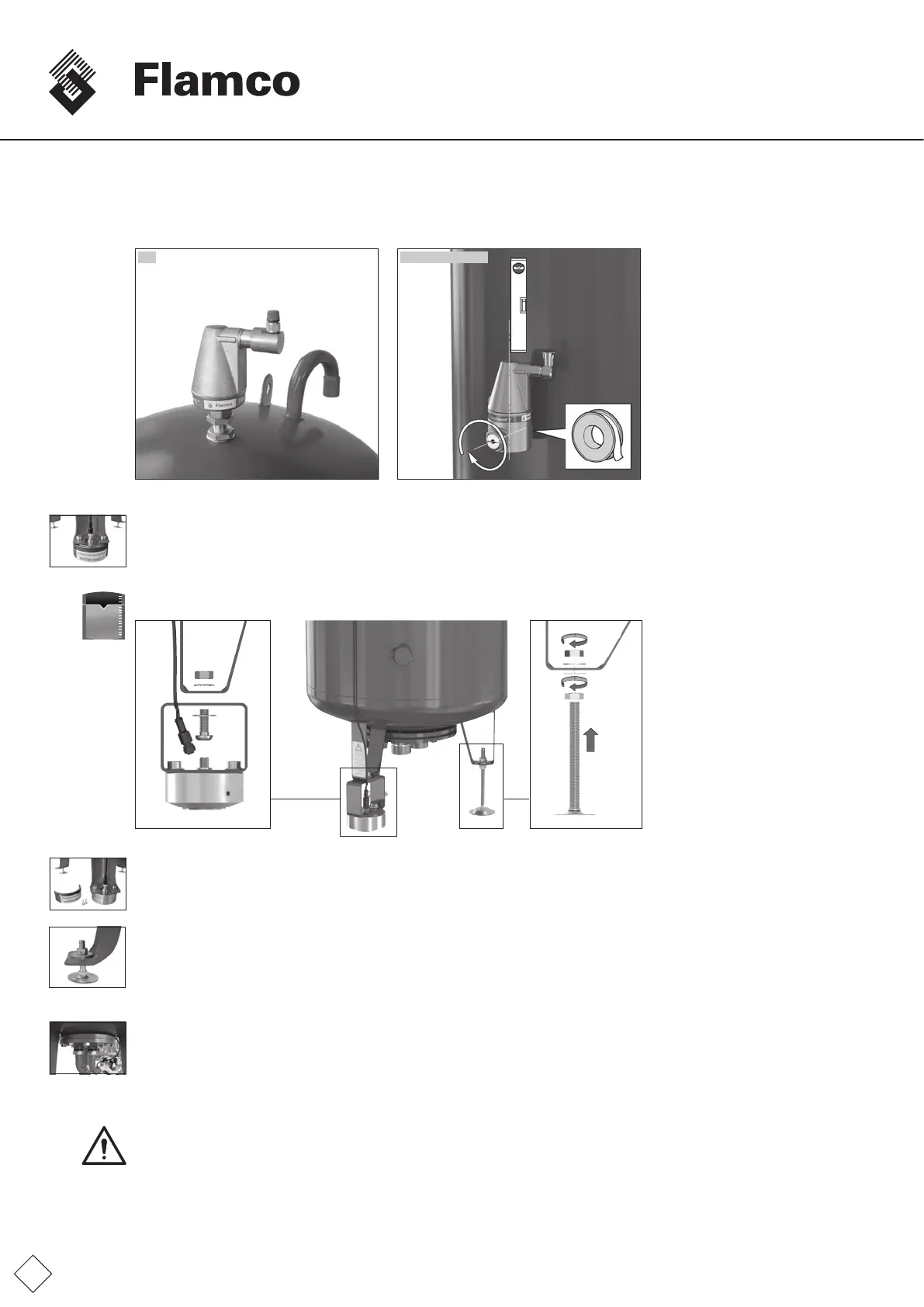

6.2 Vessel connection

Thevesselconnectionisproducedasanelectricorhydraulicconnectiontothepumpmodule.Fortheinstallationdiagram

andexampleinstallationseeappendix1.Pleaseobservethefollowingpointspriortollingandcommissioningofthepressure

expansionvessels:

• Installtheconnectionassemblybetweenthevesselandthecontrolmodule.

Caution:Ensurethattheconnectionbetweenthepumpmoduleandthebasicvesselismadewiththesuppliedexiblepressure

hoses(connectionassembly).

Fig. FM.030.V01.15

1000 Ltr

≤

Fig. FM.031.V01.15

Fig. FM.032.V01.15

Fig. FM.033.V01.15

Loading...

Loading...